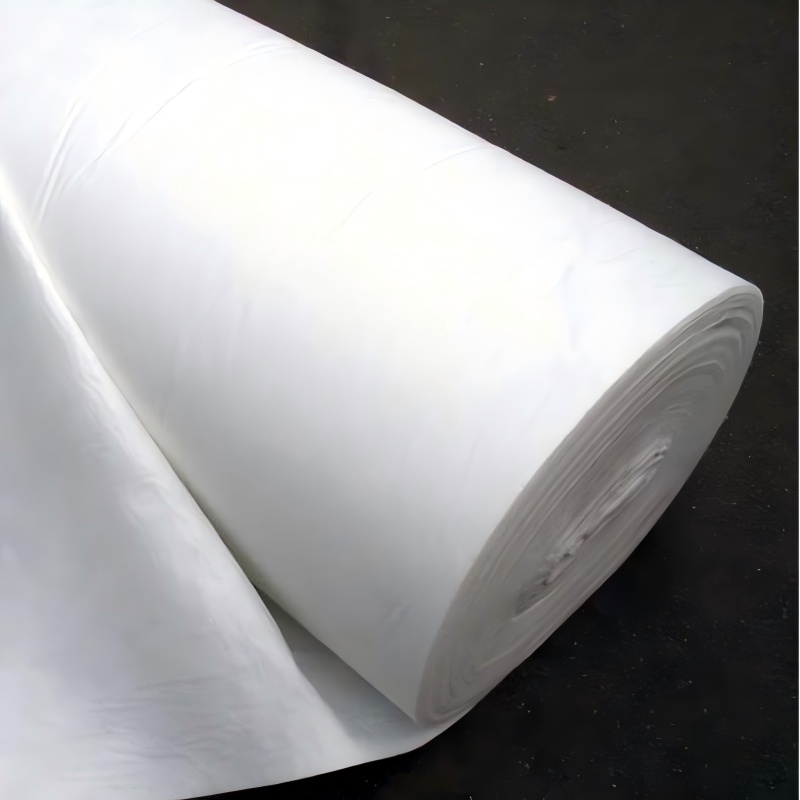

Geotextile 300g m2

1. Engineering stability:

Enhance the shear strength of soil to prevent foundation settlement or landslides.

2. Cost effectiveness:

Replace traditional sand and gravel materials, reduce construction costs and schedule.

3. Environmental friendliness:

Reduce the extraction of natural materials, and some materials can be recycled.

4. Multifunctionality:

Woven, non-woven, or composite geotextiles can be selected according to different needs.

Product Introduction:

Geotextile 300g m2 is a permeable geosynthetic material made from synthetic fibers such as polyester and polypropylene through needle punching, weaving, or thermal bonding processes. The finished product is in the form of a cloth, with a width of typically 4-6 meters and a length of up to 50-100 meters. According to the production process and function, geotextiles can be divided into three categories:

Non woven geotextile: Short fibers or long fibers are fixed into a three-dimensional mesh structure through needle punching or thermal bonding processes, with strong permeability and low cost, suitable for isolation and filtration scenarios.

Woven geotextile: woven from synthetic fibers into a regular grid, with high strength and strong deformation resistance, commonly used for reinforcement and load-bearing engineering.

Composite geotextile: Combining non-woven fabric with PE film (such as one cloth and one film, two cloths and one film), it has both anti-seepage and drainage functions and is suitable for anti-seepage engineering.

Core Features

1. High strength and durability:

Synthetic fibers endow geotextiles with excellent tensile strength, which can maintain stable performance in both dry and wet conditions. The tensile strength can reach 2-3 times that of short fiber geotextiles (long fiber geotextiles).

Wear resistance, anti-aging, service life up to decades, adapt to extreme environments (such as frozen soil, high temperature).

2. Permeability and Filtration:

The pores between fibers allow water flow to pass through while blocking sediment and fine particles, preventing soil erosion. For example, in dam engineering, long fiber geotextile can be used as a filter layer to protect the stability of the dam structure.

3. Corrosion resistance and antimicrobial properties:

Long term corrosion resistance in soil and water with different pH levels, without damage from microorganisms or insects, suitable for chemical contaminated sites or humid environments.

4. Construction convenience:

The material is lightweight, flexible, easy to transport, cut and lay, and can be sewn, welded or naturally overlapped, greatly reducing construction costs and time.

5. Environmental Protection and Economy:

Non toxic and harmless, recyclable, reducing natural stone mining; Single layer materials achieve multiple functions of isolation, drainage, and protection, reducing overall costs by more than 30%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Traffic engineering:

Highway/railway subgrade: Lay non-woven geotextile to isolate soft soil layers and fillers, prevent material mixing, and improve bearing capacity. For example, the permafrost area of the Qinghai Tibet Railway uses geotextile isolation layers to effectively solve the problem of frost heave.

Slope protection: Short fiber needle punched geotextile covers the slope surface, combined with grass planting to achieve ecological slope stabilization and reduce soil erosion.

2. Water conservancy engineering:

Dam anti filter layer: Long filament geotextile allows water flow but blocks sediment, protecting the dam structure.

Drainage system: Three dimensional geotextile is buried in soft soil areas to guide groundwater discharge and prevent roadbed collapse.

3. Environmental engineering:

Landfill site: Composite geotextile (cloth+membrane) is used to construct an anti-seepage barrier to prevent pollutants from seeping into groundwater.

Ecological restoration: Cover polluted soil with short fiber cloth, isolate harmful substances, and promote vegetation restoration.

4. Municipal engineering:

Underground engineering: Textile geotextile reinforcement is used in subway tunnels to resist soil pressure deformation.

Sponge City: Permeable geotextile is laid on the lower layer of permeable pavement to enhance rainwater infiltration and storage capacity.

5. In the field of agriculture:

Farmland drainage: Wrap the drainage pipes with geotextile to prevent soil blockage and improve drainage efficiency.

Greenhouse: As a foundation reinforcement material, it enhances the stability of the greenhouse.

6. Family scene:

Garden weed prevention: Laying geotextile to suppress weed growth while ensuring breathability and permeability.

Emergency leak prevention: Temporarily cover the leaking points on the roof or balcony to guide rainwater drainage.

Moving and storage: Fragile items in the package are scratch resistant and placed at the bottom of the carriage to prevent the goods from sliding.

Geotextile has become an indispensable material in modern engineering construction due to its multifunctionality, economy, and environmental friendliness. With the development of material technology, new types of geotextiles continue to emerge, further expanding their application boundaries and providing more reliable solutions for engineering safety and ecological protection.