Construction Site Access Roads: Stabilizing Soft Ground with Woven Geotextile

Introduction: The Critical Challenge of Soft Ground Access

Every development challenge starts with access, however soft, unstable floor can give up development earlier than it even starts. Weak subgrades—saturated clay, natural silt, or free sand—lack the energy to aid heavy development traffic, main to ruts, differential settlement, and project-paralyzing mud. Traditional strategies like over-excavation and alternative with imported mixture are regularly prohibitively high priced and time-consuming. Today, engineers and contractors increasingly more turn to a greater wise and not pricey first step: the set up of high-strength woven geotextile. This engineered material acts as a foundational reinforcement layer, reworking susceptible soils into stable, dependable systems for brief roads, laydown areas, and crane pads. This article explores how woven geotextiles supply an imperative answer for development get admission to over smooth ground, making sure tasks remain on time table and inside budget.

The Science of Separation and Stabilization: How Woven Geotextile Works

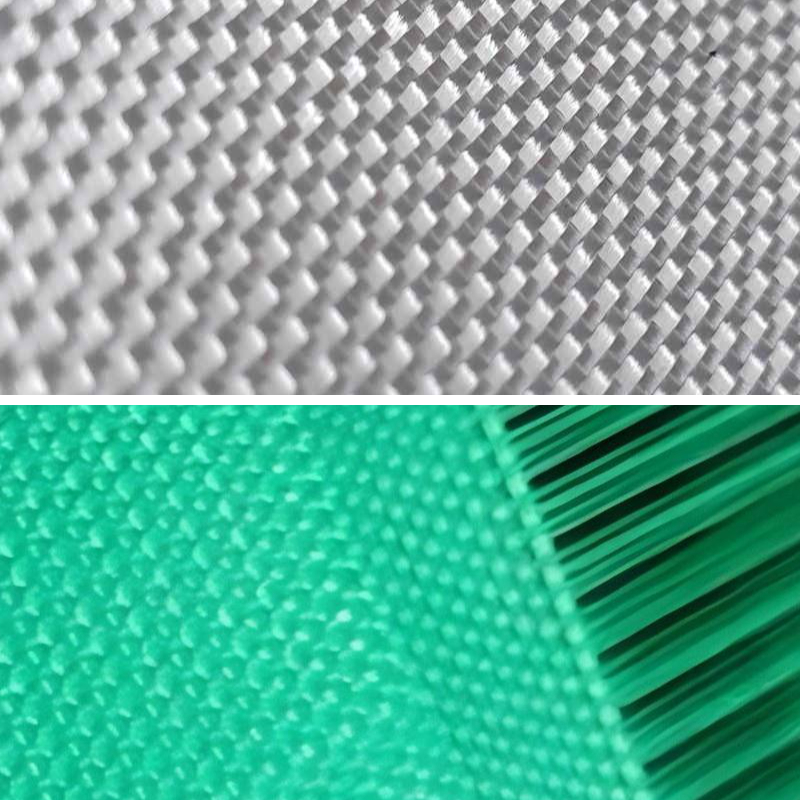

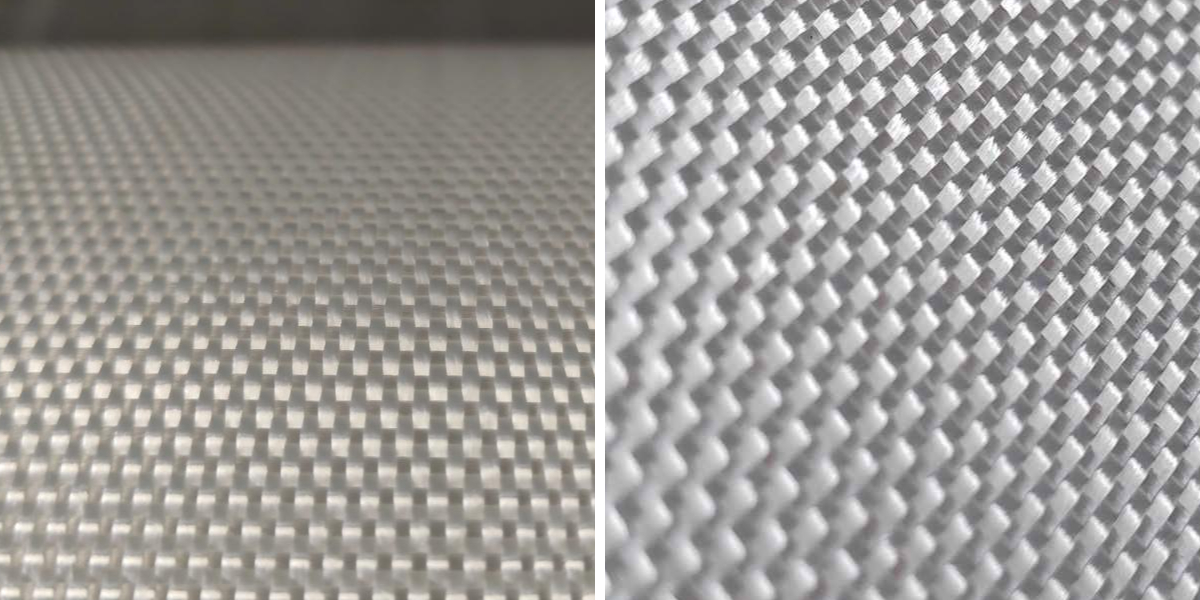

Woven geotextiles are manufactured from high-tenacity polypropylene or polyester yarns woven into a stable, permeable material with excessive tensile strength. Their overall performance in floor stabilization hinges on three core mechanical functions: separation, reinforcement, and filtration.

Separation is the principal role. When positioned between the vulnerable subgrade and the overlying gravel base course, the geotextile prevents the two materials from intermixing. Without this barrier, the mixture would punch down into the smooth soil, and the nice soil particles would contaminate the aggregate, extensively decreasing its load-bearing capacity. The material continues the structural integrity of the mixture layer intact.

Reinforcement is carried out via the fabric's tensile strength. As load is applied, the geotextile stretches slightly, mobilizing its energy to distribute the load over a wider region of the vulnerable subsoil. This reduces factor pressures and confines the soil, efficiently growing a stiff, mattress-like basal reinforcement geotextile layer that improves the common composite system's performance.

Filtration lets in for vital pore water strain dissipation. The fabric's managed permeability lets water from the harassed soil omit vertically into the drainage layer above besides permitting enormous soil particle migration. This characteristic is quintessential for retaining soil power and accelerating consolidation beneath load.

Key Types and Specifications for Access Road Applications

Selecting the right woven geotextile is fundamental for assignment success. Key overall performance warning signs encompass tensile power (Grab and Wide-Width), puncture resistance (CBR), and permeability. For most get admission to avenue applications, a robust, high-strength woven geotextile is specified.

For Basal Reinforcement: The main layer at once on the subgrade requires excessive tensile energy and terrific puncture resistance. This basal reinforcement geotextile is the workhorse, designed to face up to the set up stresses of combination and the dynamic masses of repeated heavy traffic.

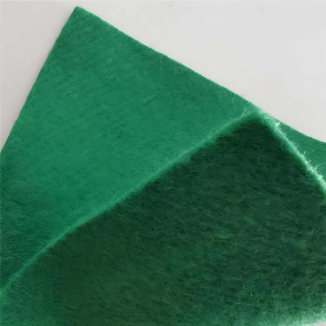

For Erosion Control: On slopes adjoining to the get admission to street or in areas the place runoff is a concern, an Erosion Control Woven Geotextile serves a twin purpose. It stabilizes the soil floor from raindrop affect and overland float whilst additionally offering reinforcement. Its specs may additionally stability electricity with most beneficial permeability for vegetative increase if everlasting seeding is section of the plan.

For Drainage Systems: While non-woven geotextiles are frequently used as filters, a Drainage System Woven Geotextile with greater permeability can be special to wrap round subsurface drains or French drains beside the get admission to road. It prevents fantastic soil from clogging the drainage combination whilst making sure environment friendly water go with the flow away from the stabilized platform.

Step-by-Step Installation Guide for a Stable Access Road

Proper set up is as necessary as product selection. Following satisfactory practices ensures the geotextile performs as intended.

Site Preparation: Clear and grade the alignment. Remove giant debris, sharp objects, and vegetation that ought to puncture the fabric. The subgrade ought to be formed to supply advantageous drainage the place possible.

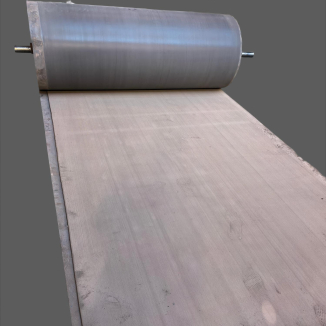

Geotextile Deployment: Rolls of woven geotextile are positioned perpendicular to the street centerline. Unroll the material immediately onto the organized subgrade, making sure it lies flat except immoderate wrinkles. Maintain minimal overlaps (typically 12 to 36 inches, as specified) between adjoining rolls. For quintessential basal reinforcement geotextile applications, seams may also be stitched or pinned to forestall separation below load.

Anchor and Protect: Secure the cloth at the edges the usage of anchor trenches or stakes, specially on slopes. Avoid using gear immediately on the uncovered fabric; use low-ground-pressure tools for mixture placement.

Aggregate Placement: Dump the first raise of chosen combination (usually a clean, overwhelmed stone) from the part of the cloth inward. Spread the cloth the use of a music loader or dozer, working in a manner that minimizes cloth distortion. Build up the combination layer to the designed thickness in managed lifts.

Compaction: Compact the mixture thoroughly. The woven geotextile confines the layer and enhances compaction efficiency, growing a stiff, unified structural section.

Economic and Project Benefits: More Than Just Fabric

Investing in woven geotextile stabilization grants tremendous returns throughout the task timeline.

Reduced Aggregate Consumption: By stopping infection and enhancing load distribution, geotextiles frequently enable for a decreased thickness of luxurious imported aggregate, main to direct fabric savings.

Increased Construction Speed: Access roads can be constructed quicker except ready for floor enchancment or dealing with steady restore of rutted paths. This continues tools and deliveries moving, a integral agenda advantage.

Improved Safety and Accessibility: Stable, mud-free roads beautify web site security for all automobiles and personnel, regardless of climate conditions. They grant dependable get entry to for emergency vehicles.

Environmental Protection: The material minimizes soil disturbance and the want for excavation. When used as an Erosion Control Woven Geotextile on adjoining slopes, it prevents sediment runoff, defending neighborhood waterways and making sure compliance with environmental regulations.

Ease of Demobilization: For brief roads, the geotextile helps clean-up. The combination stays notably uncontaminated and can frequently be recycled or reused elsewhere.

Beyond the Access Road: Related Site Applications

The utility of woven geotextiles extends a long way past the predominant haul road.

Laydown Yards and Storage Areas: Creating secure pads for cloth storage prevents sinking and loss.

Crane and Heavy Equipment Pads: Provides the crucial basis for integral lifts, making sure level, steady aid for outriggers or crawler cranes.

Working Platforms for Foundations: In moist conditions, a geotextile-reinforced platform lets in piling rigs, excavators, and different gear to work safely at the basis location.

Temporary Erosion Control: As an Erosion Control Woven Geotextile, it can be used for slope stabilization, ditch linings, and silt fence options all through construction.

Conclusion: Building a Solid Foundation for Project Success

A development website online is solely as handy as its weakest ground. Specifying and putting in a high-performance woven geotextile is a proven, cost-efficient engineering method to overcome the pervasive assignment of smooth subgrades. By supplying fundamental separation, tensile reinforcement, and filtration, this versatile fabric creates a composite gadget that turns bad soil into a strong, long lasting platform. From its core characteristic as a basal reinforcement geotextile to its roles in erosion manage and bettering web page drainage systems, woven geotextile is an integral device for contemporary construction. For challenge managers, civil engineers, and earthwork contractors, making geotextile stabilization the first step of website online work is a decisive go towards making sure smoother, safer, and greater comparatively cheap challenge execution from the floor up.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province