Geotextile 400g m²

1. High weight and strong load-bearing capacity: The weight of 400g/㎡ brings stronger structural strength, which can withstand the crushing of heavy vehicles and equipment, suitable for high load scenarios.

2. Excellent barrier performance: The tight fiber structure effectively separates different soil layers, prevents particle mixing, and maintains the stability of the engineering structure.

3. Outstanding durability: Thickened material enhances tear and wear resistance, longer service life in complex environments, and reduces replacement frequency.

4. Good water stability: While ensuring permeability, it can stabilize soil moisture and reduce the loss of base caused by rainwater erosion.

5. Wide applicability: It can be used in various high-intensity demand scenarios such as road base, water conservancy projects, landscape sites, etc., with high cost-effectiveness.

Products Introduction:

Geotextile 400g m² is a high-performance geotextile with high weight, made of high-quality polyester or polypropylene fibers, processed through advanced needle punching or weaving techniques. The weight of 400g/m ² gives it a more solid structure. As an important geosynthetic material, it can play multiple roles such as isolation, reinforcement, protection, and filtration in various engineering projects. Whether it is large-scale infrastructure construction or small and medium-sized engineering operations, this geotextile can provide reliable guarantees for engineering structures with its stable performance, effectively improving the overall quality and durability of the project.

Product Features:

1. Super strong bearing capacity: The high weight of 400g/m ² endows this geotextile with excellent tensile strength and tear strength, which can easily cope with the long-term effects of heavy loads. In projects such as roads and dams that bear high pressure, it can effectively resist deformation and damage, ensuring the stability of the engineering structure.

2. Excellent isolation performance: Its tight fiber structure can accurately separate materials such as soil and sand with different particle sizes, prevent various materials from mixing with each other, avoid structural strength decline caused by material mixing, and maintain the integrity of each layer of the project structure.

3. Excellent filtration and drainage performance: While effectively blocking soil particle loss, it allows water to pass smoothly, achieving good filtration and drainage effects, reducing the pressure caused by accumulated water in the project, and lowering the risk of structural erosion.

4. Super durability: The thickened material gives it stronger resistance to wear and corrosion, and can resist the erosion of natural factors such as acid and alkali substances, microorganisms, and ultraviolet rays. It can also maintain stable performance in harsh environments, greatly extending its service life.

5. Wide adaptability: It has good flexibility and plasticity, and can be flexibly cut and laid according to the terrain and size requirements of different projects. The construction process is convenient and efficient, and can adapt to various complex engineering environments.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

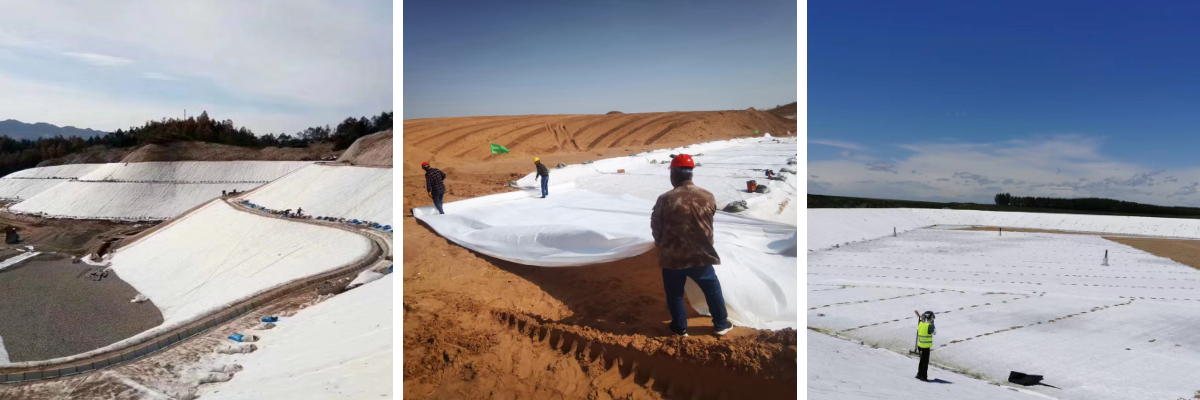

1. Road engineering: In the roadbed treatment of highways and railways, laying Geotextile 400g/m ² can enhance the bearing capacity of the roadbed, reduce roadbed settlement, and also serve as isolation and filtration to prevent the mixing of roadbed soil and base materials, thereby improving the service life of the road.

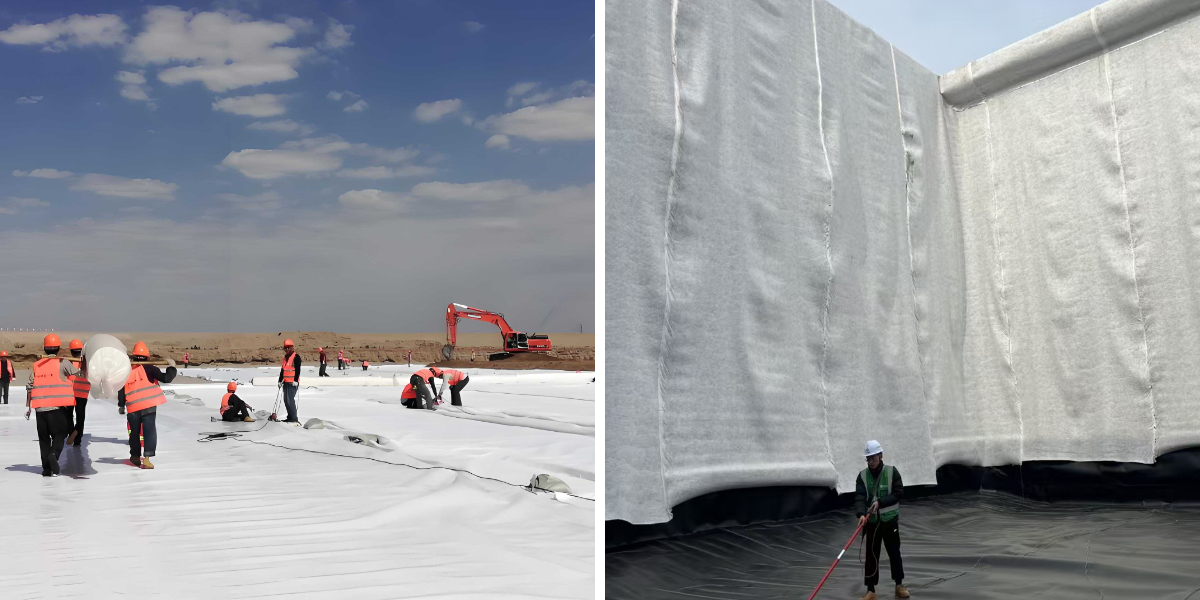

2. Water conservancy engineering: Suitable for the construction and repair of water conservancy facilities such as dams and channels, it can effectively reinforce dam structures, prevent soil erosion, and reduce the pressure caused by water accumulation through its drainage performance, ensuring the safe operation of water conservancy projects.

3. Municipal engineering: In municipal pipeline laying, landfill and other projects, it can be used as an isolation layer and protective layer to prevent harmful substances from penetrating, protect the surrounding environment, and enhance the stability of the engineering structure.

4. Mining engineering: In scenarios such as tailings treatment and yard construction in mines, this geotextile can serve as an isolation, reinforcement, and filtration agent, reducing environmental pollution caused by slag leakage and ensuring the safe operation of mining engineering.

5. Construction engineering: Used for building foundation treatment, underground garage roof drainage, etc., it can improve the bearing capacity of the foundation, optimize the drainage system, and reduce the damage to the building structure caused by groundwater problems.

Geotextile 400g/m ², with its high weight advantage of 400g/m ², has outstanding features such as super load-bearing capacity, excellent isolation performance, excellent filtration and drainage performance, super durability, and wide adaptability. Its application scenarios cover multiple fields such as road engineering, water conservancy engineering, municipal engineering, mining engineering, and construction engineering. In various engineering projects, it can effectively improve the stability and durability of engineering structures, reduce maintenance costs, and play a positive role in environmental protection. It is a high-quality geotextile product with reliable performance and strong practicality, providing strong guarantees for the smooth and long-term stable operation of various projects.