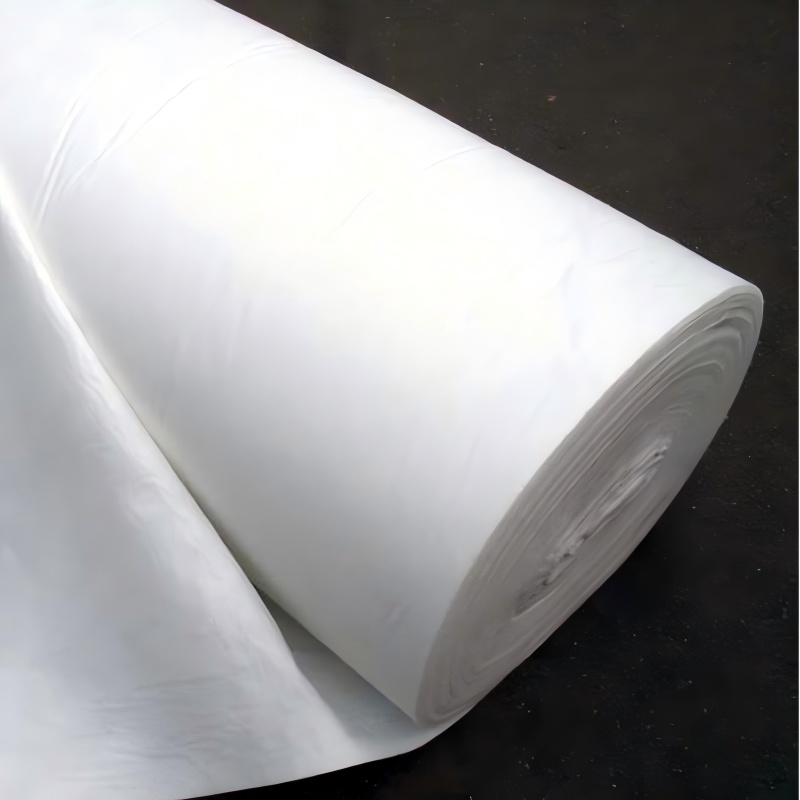

Geotextile 200gr

1. High strength and durability : Made of synthetic fibers, it has excellent tensile, tear, and puncture resistance properties. Corrosion resistant and resistant to microbial erosion, suitable for harsh environments.

2. Excellent permeability and filtration function : Allow water to pass freely while effectively preventing soil particle loss, preventing clogging, and maintaining structural stability.

3. Isolation and anti-seepage function : Prevent mixing of different materials and maintain clear structural layering.

4. Convenient construction and cost savings : Lightweight, easy to transport, lay, and cut, significantly reducing labor and machinery costs, lowering project costs, and shortening construction periods.

Product Introduction:

Geotextile 200gr is a permeable geosynthetic material made of synthetic fibers through needle punching or weaving.

Classified

by manufacturing process: Needle punched non-woven geotextile, made of polyester short fibers or polypropylene short fibers through needle punching method; Weaving geotextiles made from synthetic fibers such as polyester and nylon through weaving techniques; Non woven geotextiles are made from synthetic fibers such as polyester and polypropylene through thermal bonding or needle punching processes.

Characteristic

1. High strength: Using plastic fibers, it can maintain sufficient strength and elongation in both dry and wet conditions, and can withstand large tensile and compressive forces.

2. Corrosion resistance: It can resist corrosion for a long time in soil and water with different acidity and alkalinity, and adapt to various harsh soil and water environments.

3. Good permeability: There are gaps between the fibers, which have good water permeability, allowing water to pass smoothly while preventing the loss of soil particles.

4. Good antimicrobial properties: It is not damaged by microorganisms or insects, and can maintain stable performance for a long time.

5. Convenient construction: The material is light, flexible, and easy to transport and lay, which can reduce the difficulty and cost of construction.

6. Complete specifications: With a width of up to 9 meters, it is the widest product in China, with a unit area mass of 100-1000g/m ², which can meet different engineering needs.

Role

1. Isolation: Isolate building materials with different physical properties to prevent loss or mixing between two or more materials, maintain the overall structure and function of the materials, and enhance the load-bearing capacity of the structure.

2. Filtration (reverse filtration): When water flows from the fine soil layer into the coarse soil layer, its good breathability and permeability are utilized to allow water to pass through, while effectively intercepting soil particles, fine sand, small stones, etc., maintaining the stability of water and soil engineering.

3. Drainage: It has good water conductivity and can form drainage channels inside the soil to discharge excess liquids and gases from the soil structure.

4. Reinforcement: Enhance the tensile strength and deformation resistance of soil, strengthen the stability of building structures, and improve soil quality.

5. Protection: When water flows on the soil, it can diffuse, transmit or decompose concentrated stress, preventing the soil from being damaged by external forces and protecting the soil.

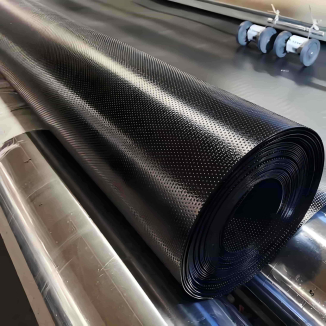

6. Anti puncture: Combined with geomembrane to form a composite waterproof and anti-seepage material, it plays a role in preventing puncture and protecting the geomembrane from sharp objects.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and Traffic Engineering

Highway and railway subgrade reinforcement

Isolation function: prevent the mixing of soft soil and gravel layer in the roadbed, and maintain structural stability.

Drainage function: Accelerate roadbed drainage and prevent moisture accumulation from causing softening.

Reinforcement function: Enhance the bearing capacity of the roadbed, reduce settlement and cracks.

Airport runway and parking lot

Prevent the mixing of base materials (such as gravel) with the underlying soil to extend their service life.

Reduce the impact of frost heave and reflection cracks.

2. Water conservancy engineering

Embankment and River Protection

Anti filter layer: prevents soil erosion caused by water flow erosion, while allowing water infiltration.

Slope protection reinforcement: combined with geogrids or gabions to enhance slope stability.

Drainage system

Used for drainage structures such as blind ditches and collection wells to prevent clogging and improve drainage efficiency.

Reservoir and channel anti-seepage

Composite geotextile (such as geomembrane+non-woven fabric) is used for anti-seepage and reducing water leakage.

3. Environmental Engineering

Landfill site

Anti leakage layer: Composite geotextile (HDPE geomembrane+non-woven fabric) prevents pollutants from infiltrating groundwater.

Drainage layer: Collect leachate to prevent pollution from spreading.

Wastewater Treatment and Artificial Wetlands

As a filtering layer, it purifies suspended solids in wastewater.

4. Construction Engineering

Basement waterproofing and drainage

Prevent groundwater infiltration while directing water flow to the drainage system.

Roof greening

As an isolation layer, it prevents soil erosion while maintaining smooth drainage.

5. Agriculture and Horticulture

Farmland drainage

Laying in underground drainage ditches to prevent soil compaction and increase crop yields.

Soil and Water Conservation

Used for slopes, terraces, etc. to prevent soil erosion.

Greenhouse greenhouse

As a ground cloth, it inhibits weed growth and maintains soil moisture.

6. Mining and tailings treatment

Tailings pond anti-seepage: prevent heavy metal pollution of groundwater.

Yard coverage: Reduce dust and prevent pollution caused by rainwater erosion.

7. Coastal and Ocean Engineering

Anti erosion and shore protection: prevent wave erosion and protect the coastline.

Artificial island construction: used for foundation reinforcement and drainage.

Geotextile has become an indispensable material in modern engineering due to its high strength, permeability, isolation, construction convenience, and environmental advantages. It can not only improve engineering quality but also reduce costs and environmental impact.