Geo Fabric

1.High mechanical strength:

Tensile strength can reach 5-80 kN/m depending on specifications, capable of withstanding long-term loads and adapting to foundation deformation.

2.Weather resistance and durability:

Resistant to UV radiation, aging, acid-base corrosion, suitable for harsh environments.

3.Good water permeability and filtration:

Permeability coefficient matches different soil conditions, enabling both drainage and stability of soil particles.

4.Convenient construction:

Lightweight and rollable, easy to cut and splice.

Product Introduction:

Geo Fabric is permeable geosynthetic materials manufactured from synthetic fibers (such as polyester PET or polypropylene PP) through needle-punching, weaving or thermal bonding processes. These engineered fabrics are widely used in civil engineering, environmental protection and infrastructure construction, providing essential functions including reinforcement, separation, filtration, drainage and protection.

Performance Characteristics:

1.Filtration: Geotextiles can effectively prevent soil particles from passing through while allowing fluids such as water and air to flow, thereby serving a filtration function.

2.Drainage: Geotextiles possess good water permeability, enabling the rapid discharge of water from the soil mass, reducing pore water pressure within the soil, and enhancing the stability of the soil.

3.Separation: Geotextiles can isolate two types of soil or materials with different properties, preventing them from mixing and maintaining their respective performance characteristics.

4.Reinforcement: Geotextiles exhibit high tensile strength and elongation, enhancing the shear strength and overall stability of the soil, thus acting as a reinforcement.

5.Protection: Geotextiles can resist erosion from natural factors such as ultraviolet radiation and chemical corrosion, protecting the soil from damage.

6.Ease of Construction: Geotextiles are lightweight, easy to cut, and simple to lay, resulting in high construction efficiency and low costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

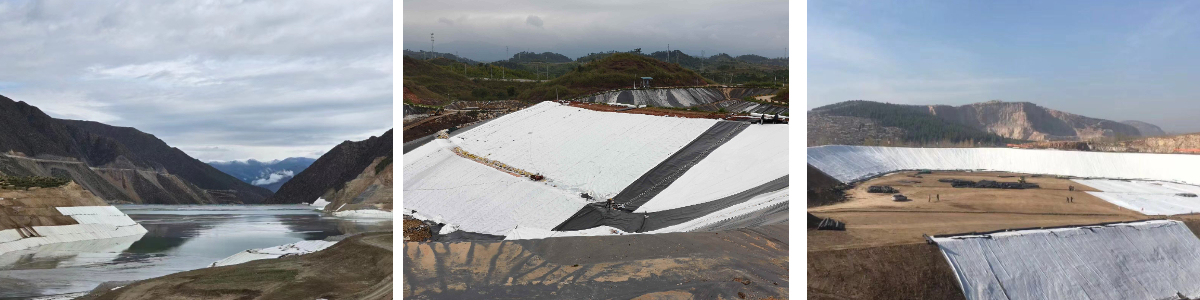

1.Hydraulic Engineering:

Dike Reinforcement: Laying geotextiles on the surface of dikes enhances their resistance to scouring and improves their stability.

Reservoir Seepage Prevention: As part of the reservoir's seepage prevention layer, geotextiles prevent water leakage from the reservoir.

Canal Lining: Laying geotextiles on the inner walls of canals reduces the scouring and erosion caused by water flow.

2.Civil Engineering:

Subgrade Reinforcement: Laying geotextiles within the subgrade enhances its load-bearing capacity and stability.

Retaining Walls: Laying geotextiles on the back face of retaining walls serves as a drainage layer, reducing the water pressure behind the wall.

Tunnel Engineering: Laying geotextiles behind tunnel linings plays a role in drainage and separation.

3.Traffic Engineering:

Highway Maintenance: Laying geotextiles at cracks on highway pavements prevents the cracks from expanding and extends the service life of the highway.

Railway Subgrade: Laying geotextiles within railway subgrades improves their stability and load-bearing capacity.

4.Environmental Engineering:

Landfill Sites: Laying geotextiles at the bottom and slopes of landfill sites prevents leachate leakage, protecting the environment.

Sewage Treatment: Laying geotextiles in sewage treatment tanks serves as a filtering layer to remove suspended solids from the sewage.