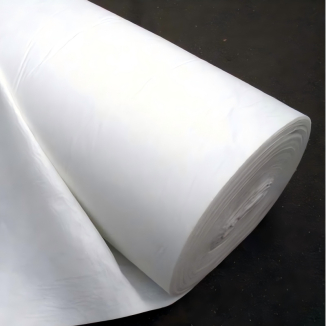

Geomembrane Sheet

1.Excellent Anti-Seepage Performance

Resistant to acid, alkali and chemical media erosion, effectively blocking liquid penetration.

2.Strong Mechanical Strength and Durability

Boasting a tensile strength of 15–35 MPa, they adapt to foundation deformation. Their buried service life exceeds 50 years, with stability in environments ranging from -70°C to +60°C.

3.Convenient and Efficient Construction

Supplied in rolls, they are easy to lay. Thermal welding ensures seam strength up to 80% of the base material, improving construction efficiency by 60% and reducing costs by 30%–50% compared to traditional solutions.

4.Environmental Friendliness and Economic Efficiency

Non-toxic and recyclable (with some degradable options), geomembranes offer low comprehensive costs, require no maintenance, and ensure long-term anti-seepage stability.

Product Introduction:

Geomembrane Sheet is an impermeable membrane manufactured from polymer materials such as polyethylene (PE), polypropylene (PP), or ethylene-vinyl acetate (EVA) copolymer through blown film extrusion, calendering, or composite processes. Its core function is to provide highly effective liquid containment, while also offering high strength, aging resistance, and easy installation, making it the essential material for modern engineering impermeable systems.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

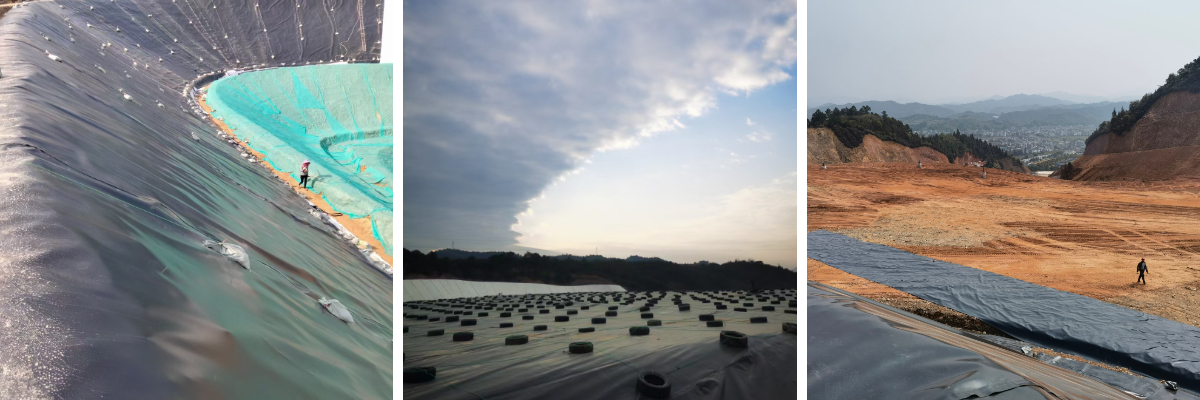

1.Environmental Engineering

Landfill Liners: Base and cover systems for solid/hazardous waste landfills.

Wastewater Treatment: Liners for oxidation ponds and sludge containment.

Hazardous Waste Storage: Multi-layer containment systems for industrial waste.

2. Water Conservancy Projects

Reservoir Seepage Control: Dam core waterproofing.

Canal Linings: Prevents water loss in irrigation channels.

Seepage Cutoff: Controls phreatic lines in embankments.

3. Transportation & Energy

Tunnel/Metro Waterproofing: Composite lining systems.

Oilfield Drilling Pits: Contains drilling mud and chemicals.

LNG Tank Foundations: Vapor barriers for cryogenic storage.

4. Agriculture & Aquaculture

Pond Liners: For fish farms and water storage.

Saline-Alkali Soil Remediation: Isolation layers for land reclamation.

Irrigation Canals: Minimizes water seepage.