Nonwoven Geotextile Fabric

•High strength and durability

•Efficient Filtration and Drainage Performance

•Environmental Protection and Sustainability

•Convenient construction and cost optimization

•Weather resistance and anti-aging

•Customized solutions

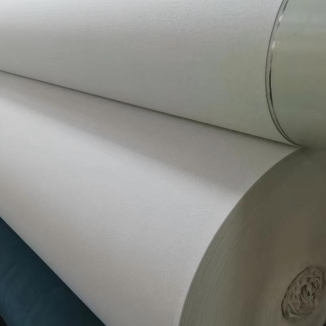

Product Introduction:

Nonwoven Geotextile Fabric is a new type of geotechnical material made from high - molecular polymers such as polyester, acrylic, nylon, and polypropylene through the needle - punching process. It combines the advantages of various fibers and has good comprehensive performance.

Product Parameters:

project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

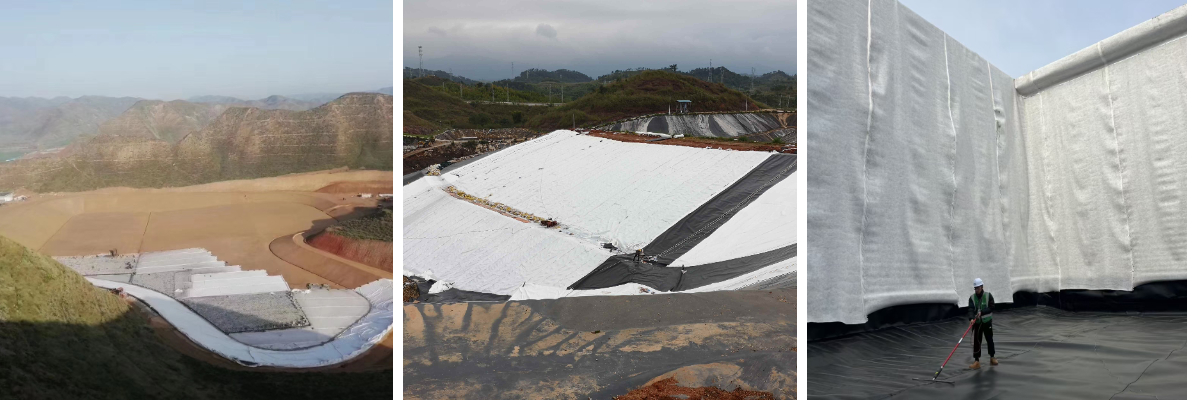

Water Conservancy Projects:

Seepage prevention: The combination of composite geotextile and HDPE membrane blocks water penetration and prevents reservoir leakage (such as the seepage prevention project of a hydropower station dam in Africa);

Drainage: Needle-punched geotextile accelerates the discharge of water accumulated in the dam body, reduces seepage pressure, and avoids the risk of piping;

Protection: Woven geotextile is used for slope and bank protection to resist water scouring and protect the soil structure of the riverbank.

Transportation Projects

Reinforcement: The long - filament geotextile enhances the tensile strength of the subgrade and reduces settlement (for example, the subgrade reinforcement of a certain highway in Southeast Asia has extended the service life by 15 years);

Separation: The short - filament geotextile separates soil layers with different particle sizes, prevents material mixing, and ensures the stability of the subgrade;

Filtration: The non - woven geotextile intercepts sediment in the subgrade water, avoids pipeline blockage, and reduces maintenance costs.

Environmental Projects

Anti-seepage and Filtration: Composite geotextiles (fabric + membrane) are used in landfill liner systems to prevent harmful leachate from contaminating the soil (meeting US EPA standards);

Soil and Water Conservation: Degradable geotextiles are used for mine greening, promoting vegetation growth and preventing soil erosion (such as the ecological restoration project in Australian mining areas);

Sludge Dewatering: High-strength geotextiles, combined with filter presses, accelerate the efficiency of sludge dewatering in sewage treatment.

Municipal & Construction

Roof Drainage: The three-dimensional composite geotextile realizes the dual functions of drainage and water retention in green roofs, reducing the building load;

Playground Reinforcement: Woven geotextiles are used for the foundation of football fields, enhancing the anti-rolling performance and maintaining the flatness of the field;

Foundation Pit Support: High-strength geotextiles are combined with soil nailing walls to improve slope stability and are suitable for deep foundation pit projects.

Agriculture & Landscaping

Farmland Moisture Conservation: Needle-punched geotextiles are used to cover farmland, reducing water evaporation and improving drought resistance (suitable for arid regions such as Middle East agricultural projects);

Green Slope Protection: Coconut fiber geotextiles (degradable) are used for slope greening, fixing grass seeds while providing nutrients to promote vegetation growth;

Saline-alkali Land Improvement: Permeable geotextiles isolate the saline-alkali layer and, in conjunction with the drainage system, reduce the soil salt content.