HDPE Membrane

• The material is non-toxic and harmless, does not pollute water and soil, can be recycled after being discarded, and meets environmental protection requirements.

• It has a long lifespan, low construction cost, outstanding cost-effectiveness in large-scale projects, and can be recycled and reused.

• It has strong environmental adaptability, can resist high and low temperatures, and is resistant to ultraviolet aging.

• It has outstanding mechanical properties, high tensile strength, good toughness, puncture resistance, deformation resistance, and can adapt to foundation settlement.

• It has excellent anti-seepage performance, a very low coefficient of permeability, and a remarkable effect in blocking liquid leakage.

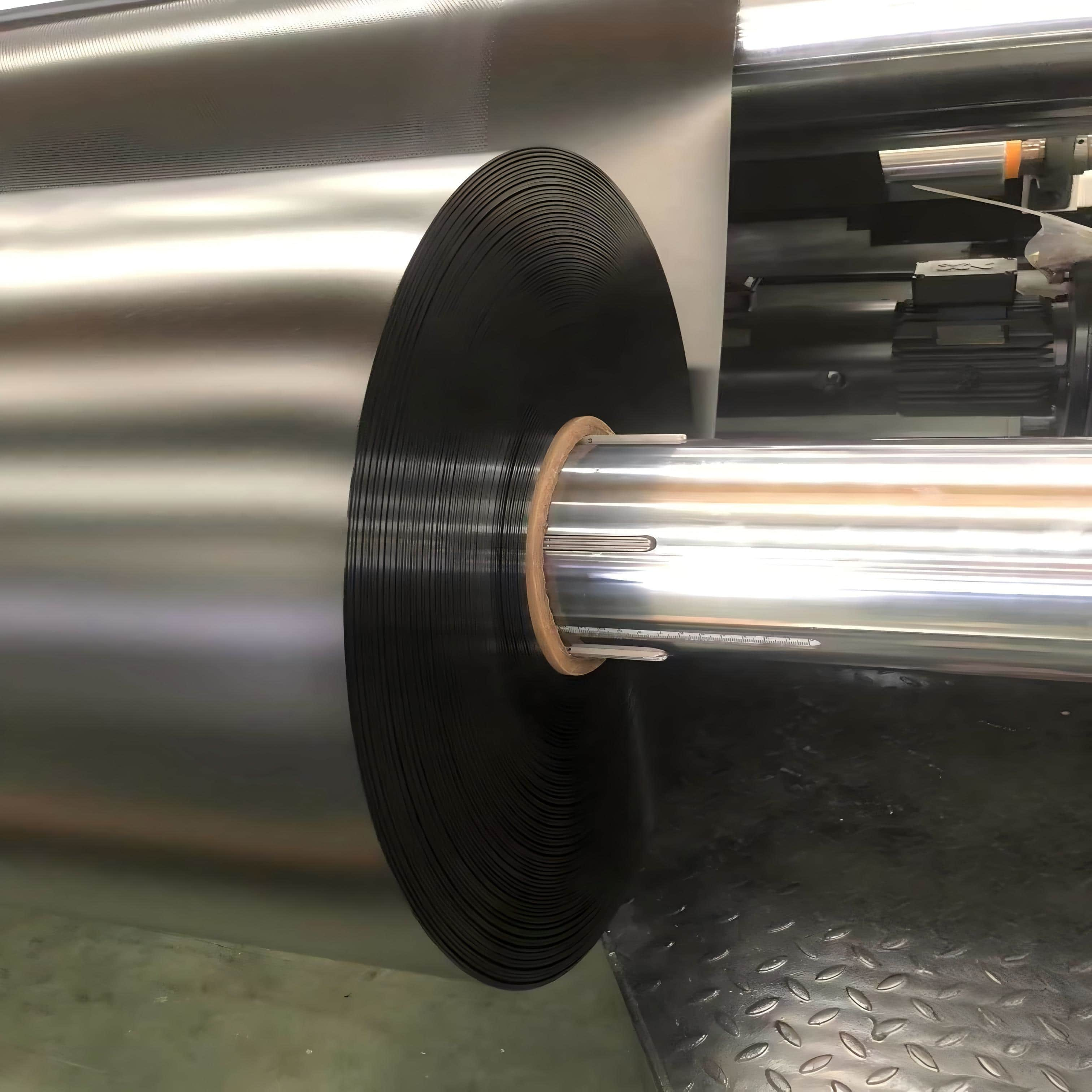

Product Introduction:

HDPE Membrane is a flexible anti-seepage material made from high-density polyethylene (HDPE) resin through extrusion calendering or blow molding processes. It features excellent impermeability, chemical corrosion resistance, and resistance to environmental stress cracking.

Performance Characteristics

1.Tensile strength: It reflects the ability of the geomembrane to resist tensile failure. Generally, the geomembrane is required to have a certain tensile strength to ensure that it will not break due to stress during construction and use.

2.Elongation at break: It indicates the maximum elongation that the geomembrane can withstand before breaking. A higher elongation at break means that the geomembrane has better flexibility and the ability to adapt to deformation.

3.Puncture resistance: It is used to measure the ability of the geomembrane to resist puncture by sharp objects. In engineering environments where sharp objects may be present, such as landfills, geomembranes with high puncture resistance should be selected.

4.Chemical corrosion resistance: The geomembrane should have good chemical corrosion resistance and be able to withstand the erosion of various acids, alkalis, salts, and other chemicals to ensure its stable performance over long-term use.

5.Aging resistance: In outdoor environments, the geomembrane will be affected by factors such as ultraviolet radiation, oxygen, and temperature, leading to aging. High-quality geomembranes should have good aging resistance and be able to maintain their performance over a long period.

6.Permeability coefficient: It is an important indicator for measuring the anti-seepage performance of the geomembrane. Generally, the permeability coefficient of the geomembrane is required to be less than 10⁻¹¹ cm/s to ensure its good anti-seepage effect.

Product Parameters:

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

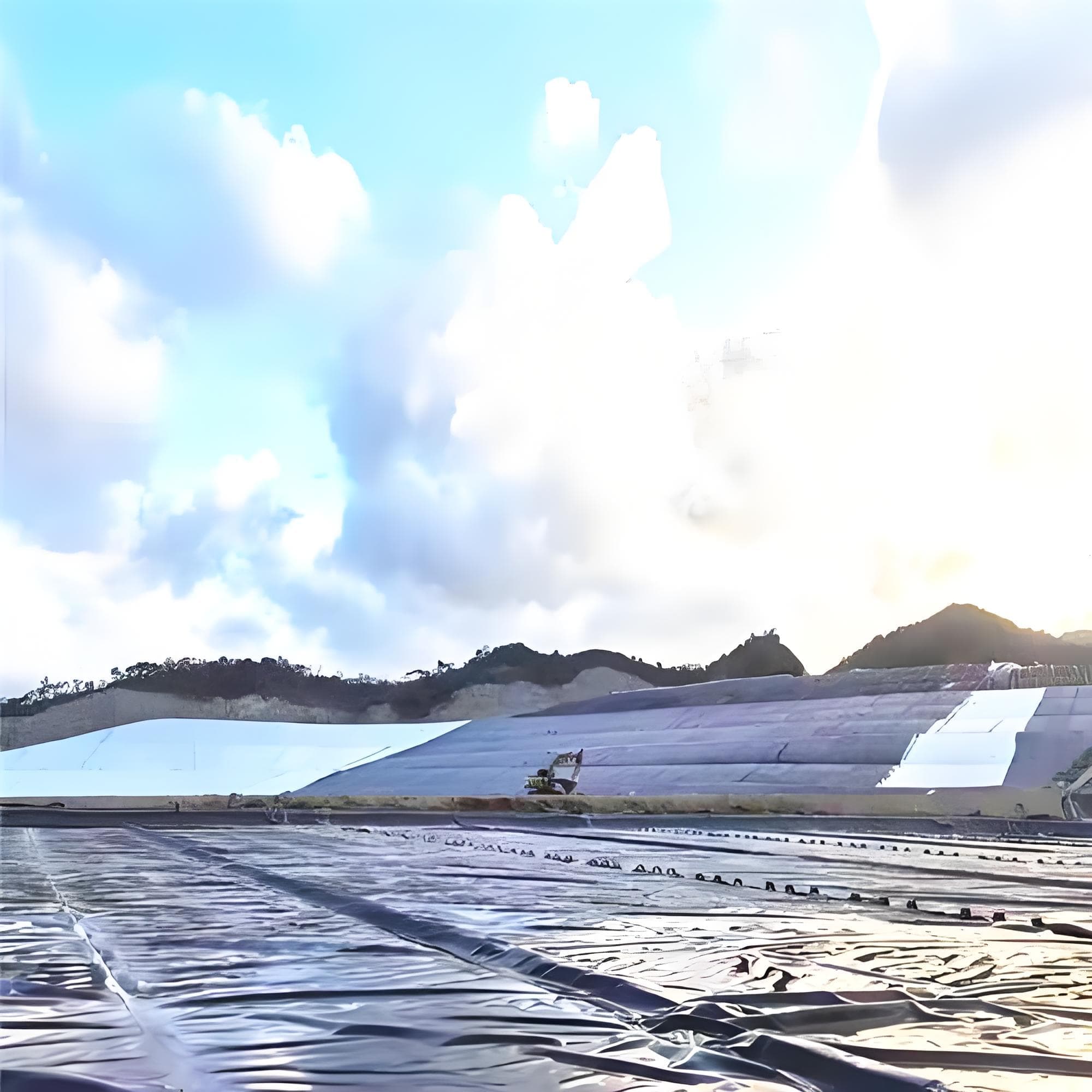

Product Applications:

1.Environmental Engineering

Landfills: Base liner systems, final cover systems

Wastewater treatment plants: Equalization ponds, anaerobic pond liners

Hazardous waste facilities: Containment of toxic substance leakage

2.Hydraulic Engineering

Reservoirs/Artificial lakes: Bottom and slope impermeabilization

Canals/Rivers: Anti-seepage lining to reduce water loss

Dams: Core walls or inclined wall seepage control structures

3.Municipal & Construction

Underground works: Waterproofing layers for basements and tunnels

Landscape water features: Impermeable liners for constructed wetlands and fountain pools

Green roofs: Root-resistant waterproofing for vegetated roofs

4.Agriculture & Mining

Livestock farms: Biogas digesters, oxidation pond liners

Tailings ponds: Heavy metal pollution containment

Salt pans/Evaporation ponds: Brine containment for crystallization