HDPE Geocell Thickness & Cell Size Guide: How to Choose for Your Project’s Load Needs

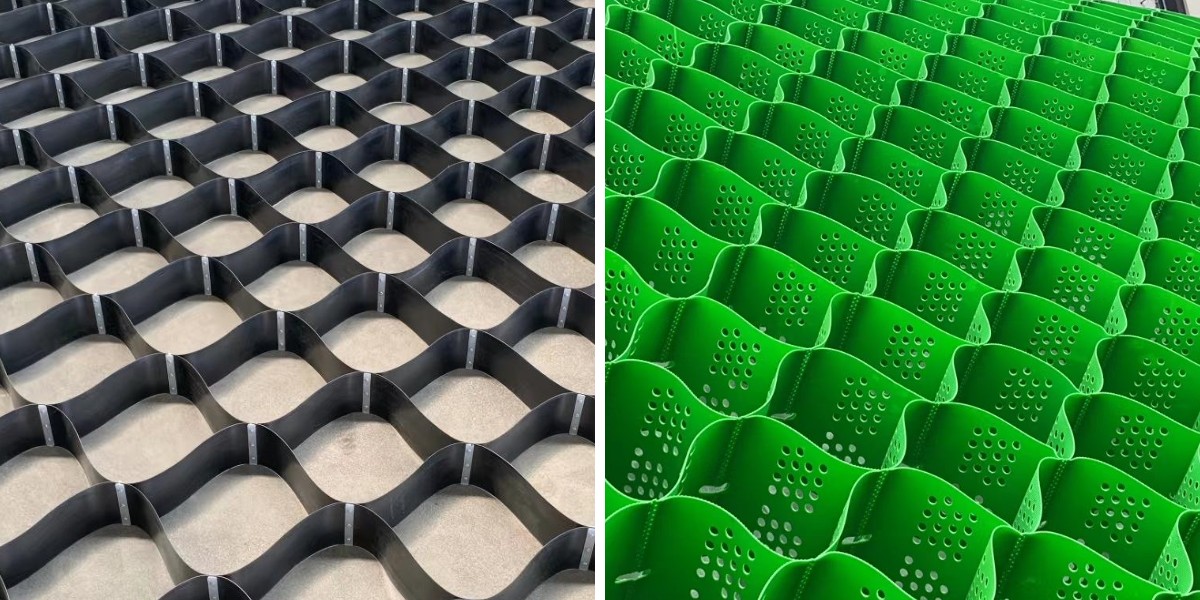

Geosynthetic substances have revolutionized civil engineering and building projects, supplying inexpensive options for soil stabilization, erosion control, and load support. Among these, HDPE geocell (High-Density Polyethylene Geocell) stands out for its versatility and durability, making it perfect for initiatives ranging from street development to slope reinforcement. However, choosing the proper HDPE geocell requires cautious consideration of thickness and mobile size—two indispensable elements that at once affect load-bearing ability and long-term performance. This information breaks down the key concerns for deciding on HDPE geocell thickness and mobilephone size, explores the position of geocell fabric properties, and highlights how these selections optimize geocell erosion manage and load management. Whether you’re working on a residential driveway or a heavy-duty industrial site, this article will assist you make knowledgeable choices tailor-made to your project’s special load needs.

1. Key Factors Influencing HDPE Geocell Thickness Selection

HDPE geocell thickness is a important determinant of its structural integrity and potential to face up to utilized loads. Thickness degrees normally from 1.5mm to 6mm, with every variant designed for precise load intensities and undertaking conditions. The choice manner have to align with three core factors: expected load magnitude, set up environment, and geocell cloth quality.

First, expected load magnitude is the most crucial factor. Light-duty projects, such as residential walkways, backyard paths, or small parking areas with occasional automobile visitors (up to five tons), can make use of thinner HDPE geocell (1.5mm–2.5mm). These thinner cells provide adequate flexibility and cost-effectiveness except compromising fundamental load support. In contrast, heavy-duty applications—including industrial yards, highways, airport runways, or areas with ordinary heavy equipment (10+ tons)—require thicker geocells (4mm–6mm). Thicker HDPE geocell boasts greater tensile energy and puncture resistance, stopping mobilephone deformation or rupture below excessive pressure.

The set up surroundings additionally influences thickness choices. Projects in harsh conditions, such as rocky terrain, areas with sharp debris, or areas susceptible to temperature fluctuations, gain from thicker geocell material. Thicker HDPE resists abrasion and UV degradation higher than thinner variants, making sure toughness in uncovered environments. Additionally, for geocell erosion manage on steep slopes or water-prone areas, thicker cells grant more suitable structural stability, stopping soil displacement even underneath heavy rainfall or water flow.

Lastly, geocell cloth fine correlates with thickness performance. High-grade HDPE geocell, even in reasonable thickness (3mm–4mm), can outperform low-quality, thinner selections due to steady fabric density and manufacturing standards. Always prioritize HDPE geocell made from virgin polyethylene, as it presents foremost chemical resistance and sturdiness in contrast to recycled blends for fundamental load-bearing applications.

2. Understanding HDPE Geocell Cell Size: Matching to Load Distribution & Soil Type

Cell size—measured as the inside dimension of every hexagonal or rectangular cellphone (typically 100mm to 600mm)—plays a pivotal function in load distribution and soil confinement. The proper telephone measurement ensures that utilized masses are evenly unfold throughout the geocell structure, decreasing stress on the underlying soil. This part explores how mobilephone dimension interacts with soil type, load type, and mission goals, along with geocell erosion control.

2.1 Cell Size and Soil Confinement

Soil kind is a key driver of mobilephone measurement selection. For fine-grained soils (clay, silt), smaller mobilephone sizes (100mm–200mm) are preferred. Smaller cells create tighter soil confinement, stopping nice particles from migrating and improving soil shear strength. This is fundamental for stabilizing susceptible subgrades in street building or slope reinforcement, the place soil motion can compromise load-bearing capacity.HDPE geocell with small cells correctly locks exceptional soils in place, growing a inflexible composite shape that distributes masses evenly.

For coarse-grained soils (sand, gravel), large cellphone sizes (300mm–600mm) are extra suitable. Larger cells accommodate the large soil particles, permitting for most excellent compaction and load transfer. These cells are perfect for heavy-duty tasks like industrial pavements or get admission to roads, the place coarse aggregates are used as infill. The geocell cloth in large cells affords ample pressure to stop combination displacement, even underneath repeated heavy loads.

2.2 Cell Size and Load Type

Different load kinds (static vs. dynamic) require tailor-made phone sizes. Static loads—such as everlasting buildings or stationary machinery—can tolerate large mobile sizes, as the load is allotted uniformly over time. Dynamic loads, along with transferring vehicles, heavy traffic, or vibration, demand smaller to medium mobilephone sizes (200mm–300mm). Smaller cells provide higher resistance to cyclic loading, minimizing geocell deformation and extending undertaking lifespan. For example, motorway tasks with steady automobile visitors count on medium mobile sizes to stability load distribution and cloth cost.

2.3 Cell Size for Geocell Erosion Control

For erosion manipulate applications, mobile dimension is linked to the severity of erosion risk. On mild slopes (less than 30 degrees) with minimal water flow, medium mobilephone sizes (200mm–300mm) are effective, as they preserve soil and vegetation whilst permitting water infiltration. On steep slopes (30 levels or more) or areas with excessive water pace (riversides, drainage channels), smaller telephone sizes (100mm–150mm) are necessary. Smaller cells create a greater compact barrier, stopping soil loss and reinforcing slope stability. HDPE geocell with small cells is additionally best for coastal erosion control, as it resists wave motion and retains sand effectively.

3. Scenario-Based HDPE Geocell Selection: Thickness & Cell Size Combinations

The superior HDPE geocell answer relies upon on the intersection of thickness, mobile size, and challenge requirements. Below are common undertaking scenarios, alongside with encouraged combinations, to illustrate how these elements work together. Each state of affairs comprises geocell fabric issues and geocell erosion manipulate wishes (where applicable).

3.1 Light-Duty Residential/Commercial Projects

Projects like residential driveways, outside patios, or small industrial parking a lot (load capacity: 2–5 tons) require a stability of cost-effectiveness and performance. Recommended: 2.0mm–2.5mm thick HDPE geocell with 200mm–300mm mobile size. This aggregate helps mild car traffic, stabilizes sandy or clay soils, and prevents minor erosion. The geocell cloth (virgin HDPE) ensures resistance to UV rays and occasional moisture, making it appropriate for uncovered out of doors environments. For areas with slight erosion threat (e.g., sloped driveways), this setup additionally affords primary geocell erosion manage by using confining soil particles.

3.2 Heavy-Duty Industrial/Infrastructure Projects

Industrial yards, warehouse floors, or secondary highways (load capacity: 10–20 tons) demand sturdy geocell solutions. Recommended: 4.0mm–5.0mm thick HDPE geocell with 300mm–400mm telephone size. Thicker geocell cloth withstands heavy equipment and cyclic loading, whilst medium mobilephone sizes optimize load distribution over coarse-grained infill (gravel or beaten stone). This aggregate stabilizes susceptible subgrades, reduces pavement thickness requirements (lowering cloth costs), and resists abrasion from heavy equipment. For industrial web sites close to water bodies, this setup additionally enhances geocell erosion manipulate round drainage areas, stopping soil contamination.

3.3 Slope Reinforcement & Erosion Control Projects

Slope stabilization (steepness: 25–45 degrees) and erosion manipulate initiatives (riversides, embankments) require geocell options targeted on soil retention and structural stability. Recommended: 3.0mm–4.0mm thick HDPE geocell with 150mm–200mm telephone size. The reasonable thickness offers sturdiness in opposition to environmental stress, whilst small mobilephone sizes tightly confine soil and vegetation roots. This aggregate prevents slope failure, reduces water-induced erosion, and promotes vegetation boom (critical for long-term erosion control). The geocell material’s UV resistance ensures sturdiness in uncovered slopes, making it appropriate for each rural and city erosion manipulate projects.

3.4 Extreme Load/Harsh Environment Projects

Airport aprons, port terminals, or initiatives in rocky/arid environments (load capacity: 20+ tons) require the most long lasting geocell solutions. Recommended: 5.0mm–6.0mm thick HDPE geocell with 100mm–150mm phone size. The most thickness resists puncture from sharp rocks and excessive loads, whilst ultra-small telephone sizes grant most soil confinement. This aggregate is best for tasks the place structural integrity is non-negotiable, such as areas with heavy plane site visitors or industrial machinery. For arid regions, the geocell cloth additionally minimizes soil moisture loss, aiding confined vegetation increase for extra erosion control.

4. Final Tips for HDPE Geocell Selection & Installation

Beyond thickness and mobilephone size, profitable HDPE geocell implementation relies upon on perfect set up and cloth quality. Always confirm that the geocell cloth meets enterprise requirements (e.g., ASTM D6637) for tensile strength, UV resistance, and chemical resistance. Prior to installation, put together the subgrade by means of casting off debris, leveling the surface, and compacting the soil—poor subgrade training can undermine even the quality geocell selection.

For load-bearing projects, make certain the geocell is stuffed with terrific infill cloth (coarse aggregates for heavy loads, exceptional soils for erosion control) and compacted fully to maximize load transfer. When the usage of HDPE geocell for erosion control, reflect onconsideration on combining it with vegetation (e.g., grass seeds, shrubs) to decorate long-term stability. Finally, seek advice from with a geosynthetic professional to tailor thickness and mobile dimension to your project’s actual load needs, as site-specific stipulations (soil type, climate, load frequency) might also require adjustments.

Conclusion

Choosing the proper HDPE geocell thickness and phone measurement is integral for assembly your project’s load requirements, making sure durability, and optimizing performance—whether for soil stabilization, load support, or geocell erosion control. By aligning thickness with load magnitude and environment, matching cellphone measurement to soil kind and load distribution, and deciding on amazing geocell material, you can create a cost-effective, long-lasting solution. From light-duty residential initiatives to heavy-duty industrial sites, HDPE geocell presents unparalleled versatility when excellent selected. Remember, investing time in appreciation these key elements will limit mission risks, minimize renovation costs, and make sure your geocell device performs as supposed for decades. For complicated projects, partnering with a geosynthetic specialist will similarly refine your selection, guaranteeing most advantageous effects for your unique load needs.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province