Geotextile 25m

1. High strength: It has good tensile and tear resistance, and can enhance soil stability.

2. Durability: corrosion resistance, anti-aging, suitable for long-term projects.

3. Permeability: allows water to pass through while preventing soil erosion, serving as a filter.

4. Convenient construction: lightweight, easy to cut and lay, reducing construction costs.

5. Environmental friendliness: It can reduce the use of natural materials and lower the impact on the environment.

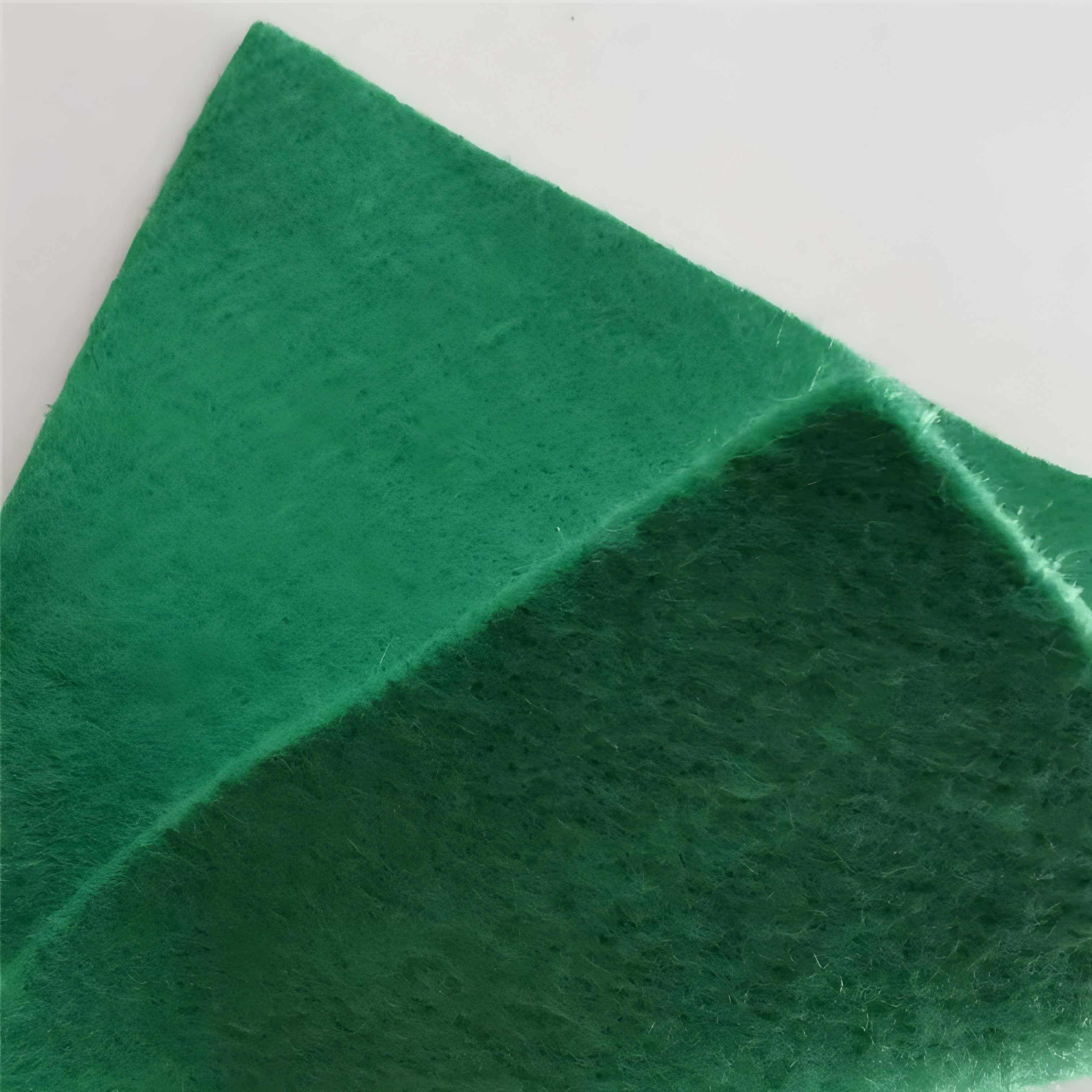

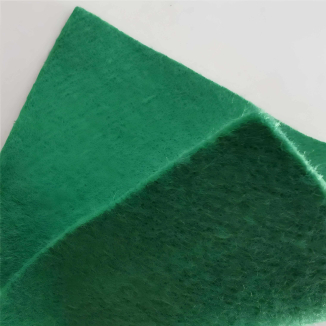

Product Introduction:

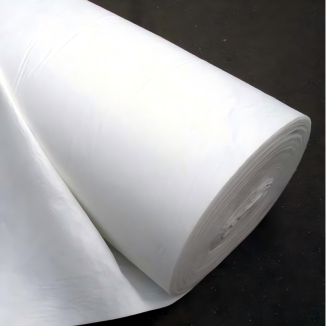

Geotextile 25m is a permeable geosynthetic material made of synthetic fibers such as polyester (PET) and polypropylene (PP) through needle punching, weaving, or thermal bonding processes. The finished product is in the form of a cloth, with a width of generally 4-6 meters (some up to 9 meters) and a length of 50-100 meters. According to the manufacturing process and structure, geotextiles can be divided into three categories:

Non woven geotextile: Short fibers or long fibers are fixed into a three-dimensional mesh structure through needle punching, thermal bonding, or chemical bonding processes. It has the characteristics of strong water permeability and low cost, and is suitable for isolation and filtration scenarios.

Woven geotextile: formed by weaving synthetic fibers into a regular grid structure, such as woven or woven fabrics, with the advantages of high strength and outstanding deformation resistance, commonly used in reinforcement and load-bearing scenarios.

Composite geotextile: By combining with other materials, functional upgrades can be achieved, such as combining geotextile with geomembrane to form "one fabric, one membrane" or "two fabrics, one membrane", which has both anti-seepage and drainage functions. It is widely used in landfill sites, artificial lakes and other projects.

Core Features

1. High strength and durability:

Plastic fiber material endows geotextiles with excellent tensile, tear, burst, and puncture resistance, and can withstand complex stresses during construction and use. For example, polyester (PET) geotextile has high tensile strength and modulus, making it suitable for reinforcement projects that can withstand large loads for a long time; Polypropylene (PP) geotextile has low density, low cost, excellent acid and alkali resistance, and is commonly used in filtration and isolation scenarios.

Resistant to chemical corrosion, UV radiation, and microbial invasion, ensuring stable performance even in acidic and alkaline environments, humid conditions, or long-term exposure.

2. Permeability and filtration function:

The gaps between fibers allow water to flow smoothly while effectively intercepting soil particles, fine sand, etc., preventing soil erosion. For example, in dam engineering, geotextile serves as an anti filter layer to prevent water flow erosion from causing dam collapse.

3. Isolation and reinforcement function:

Placed between soil layers or materials with different physical properties (such as gravel and soft soil) to prevent mixing and maintain their respective design functions. Typical application: Isolate soil and sand in highway subgrade to prevent material mixing from causing collapse and extend road life.

After being buried in the soil, it provides additional tensile strength through friction, improves the overall stability of the soil, disperses local loads, and reduces uneven settlement. For example, in slope reinforcement, geotextiles act like "invisible steel bars" to enhance soil tension and reduce landslide risks.

4. Dual functions of protection and drainage:

Buffer the damage to waterproof materials caused by external impacts (such as protective geomembranes), or form flat drainage channels to collect and guide pore water or seepage water. Application scenario: Drainage of water seepage around tunnels to reduce external water pressure on lining; Waterproof protection and drainage of underground structures.

5. Environmental Protection and Economy:

Non toxic and odorless, will not cause harm to human health and the environment, and meets the requirements of green engineering.

The material is light and flexible, easy to transport, lay and construct, and can be manually or mechanically laid to adapt to complex terrains; Support connection methods such as stitching and thermal bonding to ensure construction efficiency.

Low cost and significant comprehensive benefits. For example, using geotextiles can save more than 30% of material and labor costs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Water conservancy engineering

Dam construction: used for the anti filter layer of the dam body to prevent the soil material of the dam body from being carried away by water flow; Laying on the dam slope, combined with vegetation to achieve slope protection and reduce rainwater erosion.

Channel anti-seepage: Covering the inner wall of the channel to reduce water leakage and improve irrigation efficiency.

River management: laid at the bottom of the riverbed to stabilize the river flow and prevent sedimentation caused by sediment erosion.

2. Transportation Engineering

Roadbed treatment: Lay geotextile between the foundation and roadbed filling to isolate different soil layers (such as clay and sand) and avoid uneven settlement caused by mixing; Simultaneously draining the accumulated water from the roadbed to protect its strength.

Road reinforcement: laid on the base of asphalt or cement pavement to enhance the crack resistance of the pavement and extend the service life of the road (especially suitable for soft soil foundation sections).

Tunnel engineering: As a drainage layer behind the lining, it guides the discharge of groundwater and prevents lining seepage.

3. Municipal and Environmental Engineering

Landfill site: As an auxiliary layer of the anti-seepage system, it isolates garbage from soil and prevents leachate from contaminating groundwater; Simultaneously guide the collection of leachate to the treatment system.

Wastewater treatment: used for the filter layer of sedimentation tanks and filtration tanks to purify water quality; Or as a filtering medium for sludge dewatering.

4. Geotechnical and Mining Engineering

Soft soil foundation reinforcement: Enhancing the bearing capacity of the foundation through reinforcement, reducing the settlement of buildings or structures.

Slope protection: Covering exposed slopes and fixing them with anchor rods to prevent soil erosion and landslides; Used for soil improvement and assisting vegetation restoration in mine reclamation.

5. Agriculture and Horticulture

Agricultural water conservancy: used for anti-seepage irrigation channels, drainage systems in rice fields, and improving water resource utilization efficiency.

Horticultural weed prevention: Lay on the ground to suppress weed growth, while maintaining soil permeability and reducing watering frequency.

Geotextile, with its unique performance advantages, has become the core material for solving the problem of "soil water interaction" in modern engineering, promoting the development of engineering construction towards high efficiency, environmental protection, and economy.