Geocell Ge

1.Three-Dimensional Reinforcement & Superior Load-Bearing Capacity

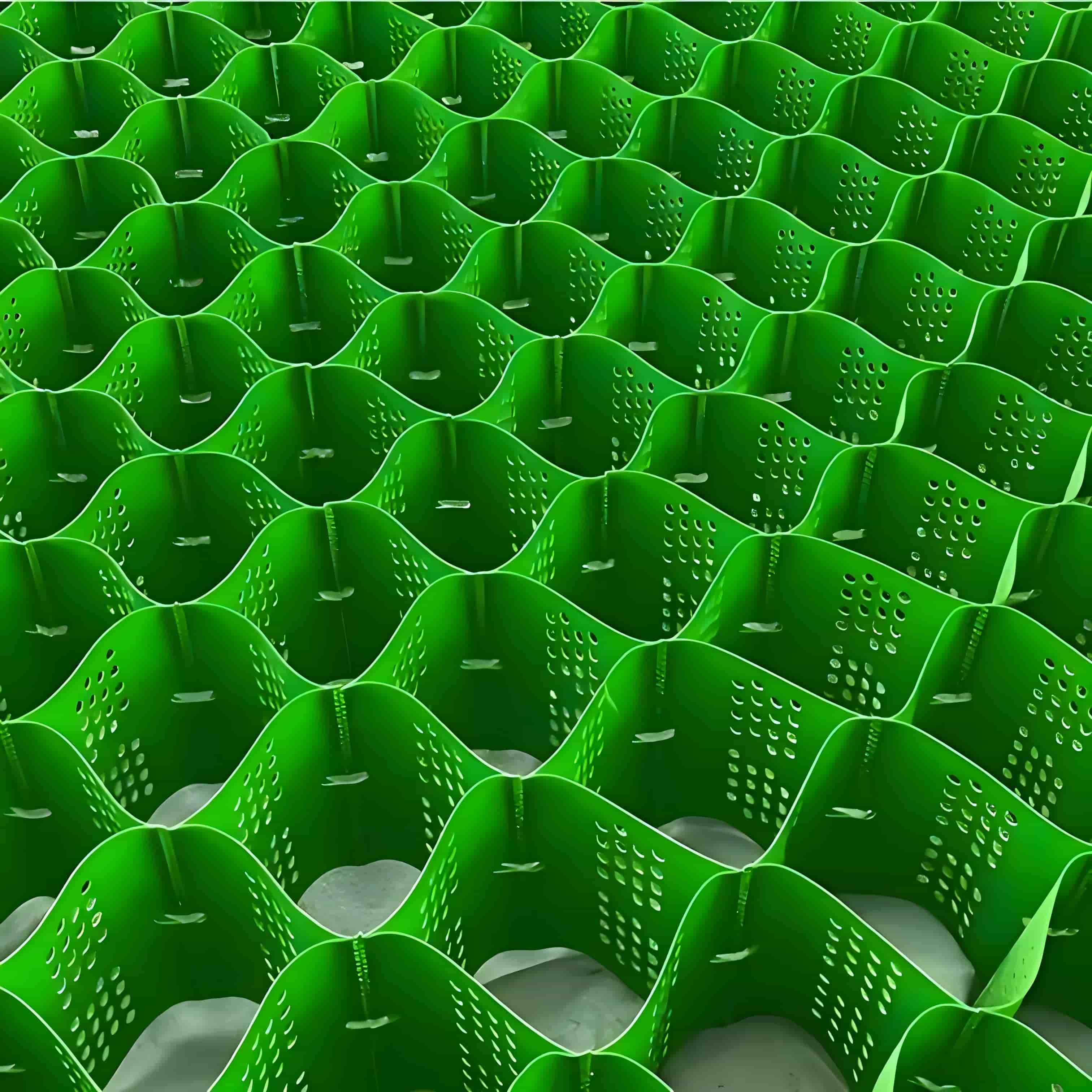

Honeycomb structure provides lateral confinement, forming a composite system with fill materials;Distributed load transfer mechanism effectively prevents differential settlement

2.High-Efficiency Ecological Protection

Open-cell design enables vegetation growth (vegetation coverage rate >90%);100% permeability maintains natural hydrological cycle

3.Exceptional Environmental Adaptability

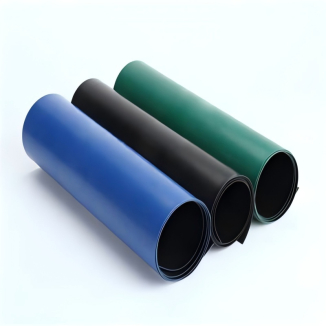

Service temperature range: -60°C to 80°C (HDPE material);UV resistance with 50-year lifespan (carbon black additives included);Chemical corrosion resistance (stable in pH 2-13 environments)

Product Introduction:

Geocell Ge is a three-dimensional honeycomb-structured geosynthetic material made from high-performance polymers (HDPE/PP) using ultrasonic welding technology. When expanded, it forms a stable 3D cellular confinement system that interacts with infill materials to create a reinforced composite structure. Widely used in civil engineering for reinforcement, protection, and drainage applications.

Feature

1.High Strength and Stiffness

Geocells, through their unique honeycomb - like net structure, can confine the fill materials within the cells, forming an integrated whole. This significantly enhances the strength and stiffness of the soil mass, thereby increasing its load - bearing capacity.

2.Lateral Restraint Effect

The cell walls exert lateral restraint on the fill materials, effectively preventing their lateral displacement. This improves the stability of the soil mass and reduces uneven settlement of the foundation.

3.Good Flexibility

Geocells possess a certain degree of flexibility, enabling them to adapt to uneven deformation of the foundation. They will not be damaged due to minor changes in the foundation, thus ensuring the long - term stability of the project.

4.Convenient Construction

Geocells are lightweight and foldable, making them easy to transport and store. During construction, they only need to be unfolded, fixed, and then filled with materials. This results in fast construction speed and high efficiency.

5.Excellent Durability

Made of high - quality plastic materials, geocells have good corrosion resistance, anti - aging properties, and weather resistance. They can be used for a long time in various harsh environmental conditions, with a long service life.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

1.Used for stabilizing railway subgrades.

2.Applied in the treatment of soft foundations for highways.

3.Employed in the management of shallow water channels.

4.Used to support pipelines and sewers.

5.Applied to prevent landslides and serve as mixed retaining walls under load.

6.Used for independent walls, docks, flood control dikes, etc.

7.When encountering soft foundations in highway construction, using geocells can greatly reduce construction labor intensity, decrease the thickness of the subgrade, enable fast construction with good performance, and significantly reduce project costs.