HDPE Impermeable Liner

1. The anti-seepage effect is absolutely reliable: its permeability is several orders of magnitude lower than the best compacted clay.

2. Save space and materials: A 1mm thick HDPE geomembrane has an anti-seepage effect equivalent to a 1m thick compacted clay layer.

3. Strong adaptability to deformation: Good flexibility allows it to adapt to uneven settlement of the foundation, while rigid materials such as concrete may crack.

4. Fast construction speed and less affected by weather: Mechanized welding operations for laying are much more efficient than layered compaction of clay, and construction can still be carried out in light rainy weather.

Product Introduction:

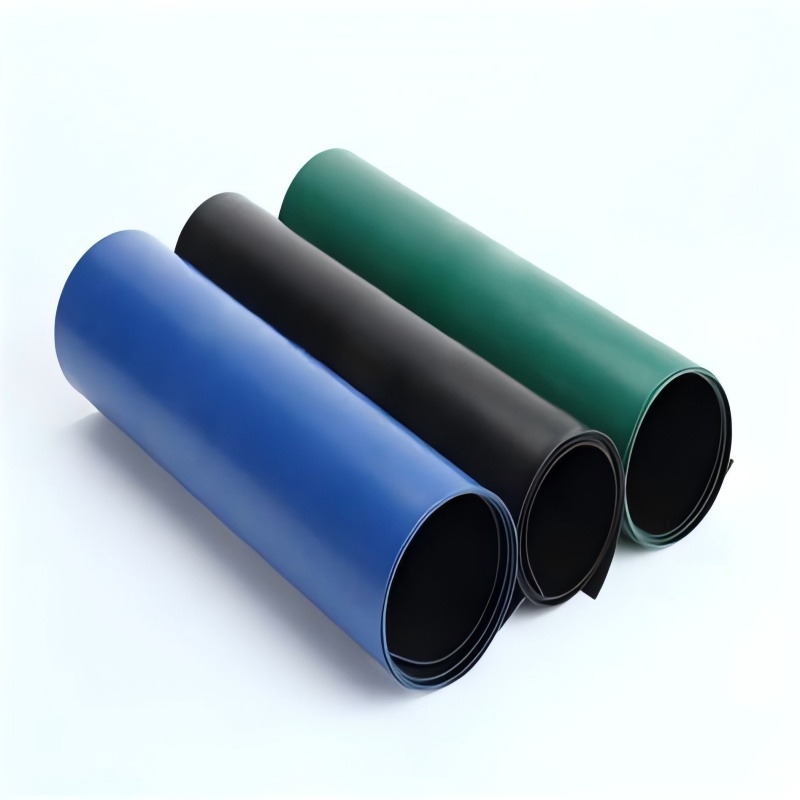

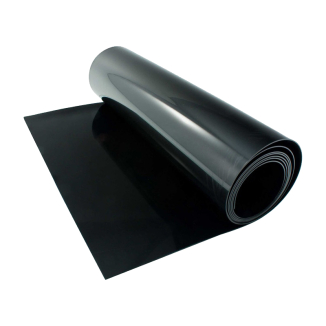

HDPE Impermeable Liner is a flexible waterproof and barrier material made from high molecular weight polymers such as polyethylene (PE), polyvinyl chloride (PVC), and ethylene vinyl acetate copolymer (EVA) through blow molding, rolling, or coating processes. Its core function is to construct an anti-seepage barrier with an extremely low permeability coefficient (usually ≤ 1 × 10 ⁻¹² cm/s), blocking the permeation path of liquids or gases. For example, the anti-seepage coefficient of HDPE geomembrane (high-density polyethylene film) can reach 1 × 10 ⁻¹⁷ cm/s, which is equivalent to only one drop of water penetrating in 100 years on an area of 1 square meter.

Feature

1. Excellent physical performance

High tensile strength: The tensile strength of HDPE geomembrane can reach over 25 MPa, with a fracture elongation of over 550%, and can withstand tensile stress caused by foundation settlement or soil displacement.

Wide temperature resistance range: The operating environment temperature covers -70 ℃ to 110 ℃, suitable for extremely cold or high temperature environments. For example, in the anti-seepage project of reservoirs in the Arctic permafrost region, HDPE film maintains flexibility even at low temperatures of -50 ℃.

Chemical corrosion resistance: It can resist strong acids (pH ≤ 2), strong alkalis (pH ≥ 12), salts, and organic solvents, and is suitable for corrosive environments such as chemical waste tanks and landfills.

2. Outstanding durability

Strong anti-aging performance: after adding carbon black and anti ultraviolet agent, the life of HDPE film under ultraviolet radiation can reach more than 50 years. For example, the HDPE film laid in a reservoir in Qinghai has been in use for 23 years, with a performance degradation rate of less than 5%.

Excellent puncture resistance: HDPE film with a thickness of 2.0mm can withstand a nail with a diameter of 10mm piercing with 100N force without damage.

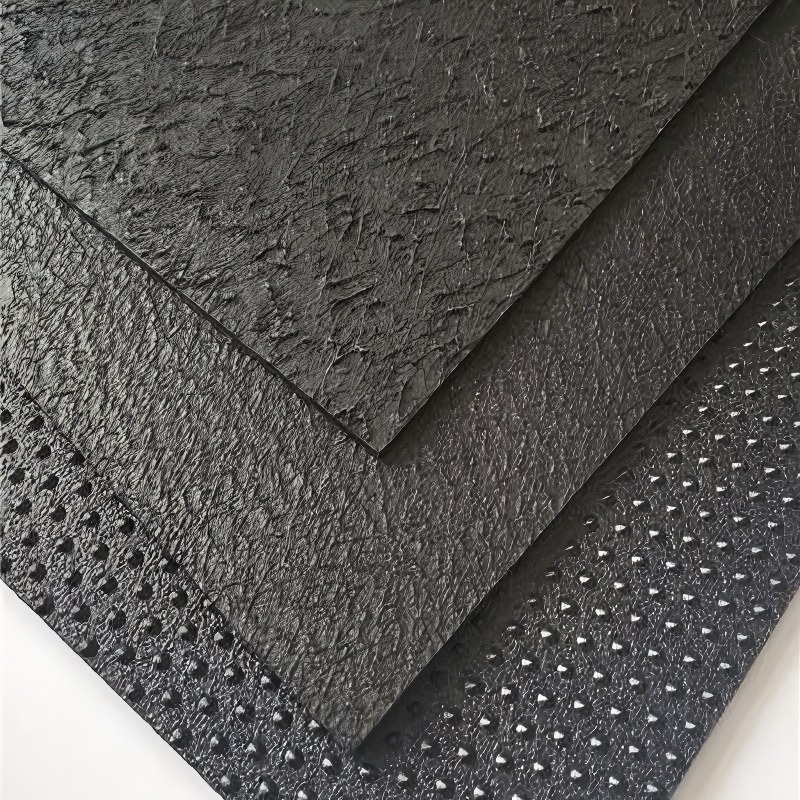

3. High adaptability to construction

Lightweight: The weight per square meter is only 0.9-2.5kg, making it easy to manually transport and lay.

Good flexibility: can fit complex terrain, such as curved river slopes or irregular landfill bottoms.

Stable welding performance: using hot melt welding technology, the weld strength can reach over 90% of the base material, forming a continuous anti-seepage layer.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

1. Water conservancy engineering

Reservoir anti-seepage: Laying HDPE film on the upstream face of the dam can reduce leakage by more than 90%. For example, the dam body of a tributary of the Three Gorges Reservoir adopts double-layer HDPE membrane for anti-seepage, reducing the annual leakage from 1.2 million cubic meters to 80000 cubic meters.

Channel anti-seepage: After laying geomembrane in irrigation channels, the water delivery efficiency is improved by 30% -50%, and the water-saving effect is significant.

2. Environmental Engineering

Landfill site: A double-layer composite geomembrane (HDPE film+GCL bentonite pad) forms a multiple anti-seepage system, effectively isolating leachate. After adopting this plan at a landfill in Beijing, the risk of groundwater pollution was reduced by 95%.

Wastewater treatment tank: PVC geomembrane is resistant to chloride ion corrosion and suitable for anti-seepage in chemical wastewater treatment tanks.

3. Transportation Engineering

Tunnel anti-seepage: EVA geomembrane is laid outside the lining of the subway tunnel to prevent groundwater infiltration and ensure construction safety. After adopting this scheme, the leakage rate of a subway tunnel in Shanghai decreased from 0.3L/(m ² · d) to 0.02L/(m ² · d).

Highway soft foundation treatment: laying geomembrane on soft soil foundation can isolate the rise of groundwater and improve the stability of the roadbed.

4. Agriculture and Fisheries

Fish pond anti-seepage: 0.5mm HDPE film can prevent water leakage and inhibit harmful substances from dissolving into the water at the bottom, thereby improving the survival rate of aquaculture. After being used in a certain aquaculture farm in Guangdong, the survival rate of fish fry increased from 75% to 92%.

Salt field covering: EVA geomembrane is used for covering the crystallization pool in salt fields, which can reduce rainwater erosion losses and improve salt production efficiency.

5. Mining and Energy

Tailings pond anti-seepage: Lay geomembrane at the bottom of the tailings pile to prevent wastewater leakage and pollution of groundwater. After adopting this plan, the heavy metal content in the surrounding soil of a copper mine tailings pond in Yunnan decreased by 60%.

Biogas pool anti-seepage: The black film biogas pool is sealed with HDPE film, which increases fermentation efficiency by 20% and gas production by 30%.

As a key geosynthetic material, geomembrane has become an indispensable "environmental protector" and "safety barrier" in modern civil, environmental, and hydraulic engineering due to its unparalleled anti-seepage performance, excellent durability, and significant economic benefits. It plays a crucial role in protecting water resources and soil environment, and ensuring engineering safety.