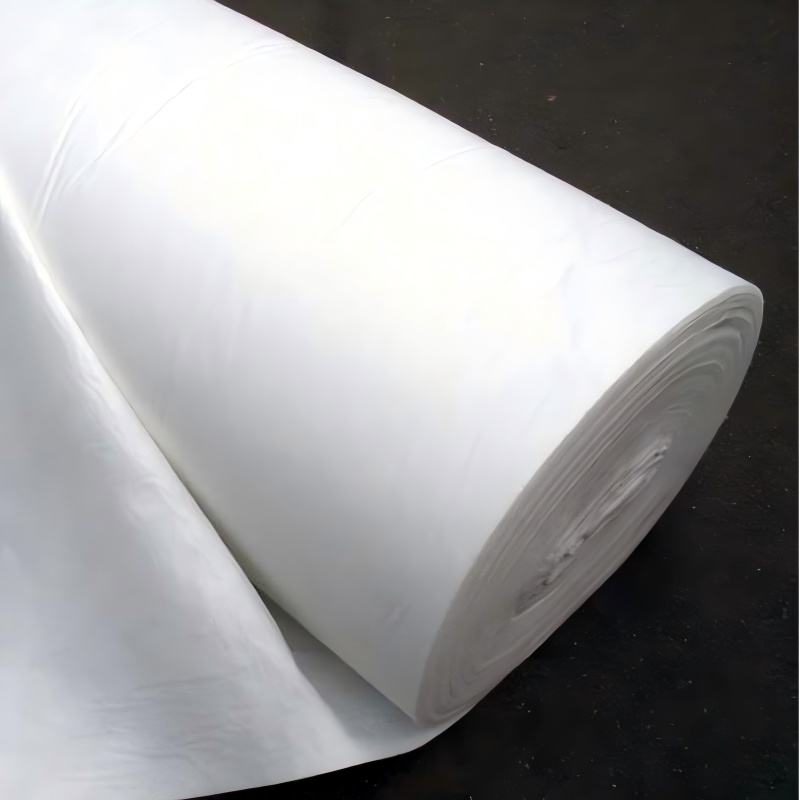

200 gsm Non Woven Geotextile

1. Strong integrity: Provides uniform stress distribution.

2. Easy to construct: lightweight, easy to transport and lay.

3. Good durability: corrosion resistance, long service life.

4. Easy to control quality: Industrial production ensures stable quality.

5. High economic benefits: saving materials, labor, and maintenance costs.

Product Introduction:

200 gsm Non Woven Geotextile is a permeable synthetic fiber material specifically used in civil engineering. It is essentially a type of 'textile fabric', but unlike traditional fabrics, its main use is not for making clothing, but as an engineering material combined with soil, rock, water, or other civil engineering materials to enhance structural performance, improve drainage, provide protection and isolation, etc.

Simply put, geotextile is the "smart fabric" in engineering, which is like putting a multifunctional jacket on the soil to solve various engineering problems.

1. Main functions

The core value of geotextile lies in its multifunctionality, which mainly includes:

Reinforcement effect:

Principle: By utilizing its high tensile strength and frictional force with the soil, local loads are dispersed over a larger area, limiting the lateral displacement of the soil and thereby improving its stability and bearing capacity.

Analogy: Similar to steel bars in reinforced concrete, geotextile serves as a "reinforcing material" to disperse stress.

Applications: steep slope reinforcement, soft foundation treatment, reinforced soil retaining walls, etc.

Isolation function:

Principle: Lay between two materials of different properties (such as gravel and soft soil) to prevent them from mixing with each other and maintain their respective structural integrity and performance.

Benefits: prevent the base stone from sinking into soft soil, save filling material usage, and extend the service life of the structure.

Application: Between road base and soft foundation, between railway ballast and roadbed, landfill liner system, etc.

Filtering function:

Principle: Allow water to pass vertically through its plane while effectively preventing excessive loss of soil particles. It forms a natural 'filter layer'.

Mechanism: The fine particles carried by the water flow will form a "filter cake" on the surface of the geotextile. This filter cake itself also has filtering properties, which can prevent the loss of finer particles and achieve dynamic balance.

Application: Drainage ditch, revetment engineering, drainage system behind retaining walls, etc.

Drainage function:

Principle: It has a certain thickness and can form a water conveyance channel in its plane to collect and discharge liquids or gases.

The difference from filtration: filtration is "vertical permeability", while drainage is "planar conductivity".

Application: Internal drainage of earth dams, foundation drainage, drainage systems for sports fields, etc.

Protective function:

Principle: As a flexible buffer layer, it absorbs and disperses external stress (such as impact and puncture), protecting the waterproof layer or other sensitive materials below from damage.

Application: Protecting HDPE anti-seepage film in landfills, serving as initial lining and protective layer in tunnel engineering, etc.

Usually, a geotextile will have multiple functions simultaneously.

2. Raw materials and manufacturing processes

Main raw materials: The vast majority are synthetic polymers, mainly polypropylene and polyester, with a few using polyamide, polyethylene, etc. These materials have excellent resistance to chemical corrosion, microbial decomposition, and long-term durability.

Main manufacturing processes and classifications:

According to the manufacturing process, geotextiles are mainly divided into the following four categories:

Craftsmanship: Similar to weaving bags, fibers (long or short) are interlaced and woven in both longitudinal and transverse directions.

Features: Stable structure, high tensile strength, low elongation, uniform pore size.

Main applications: Focusing on reinforcement and isolation functions.

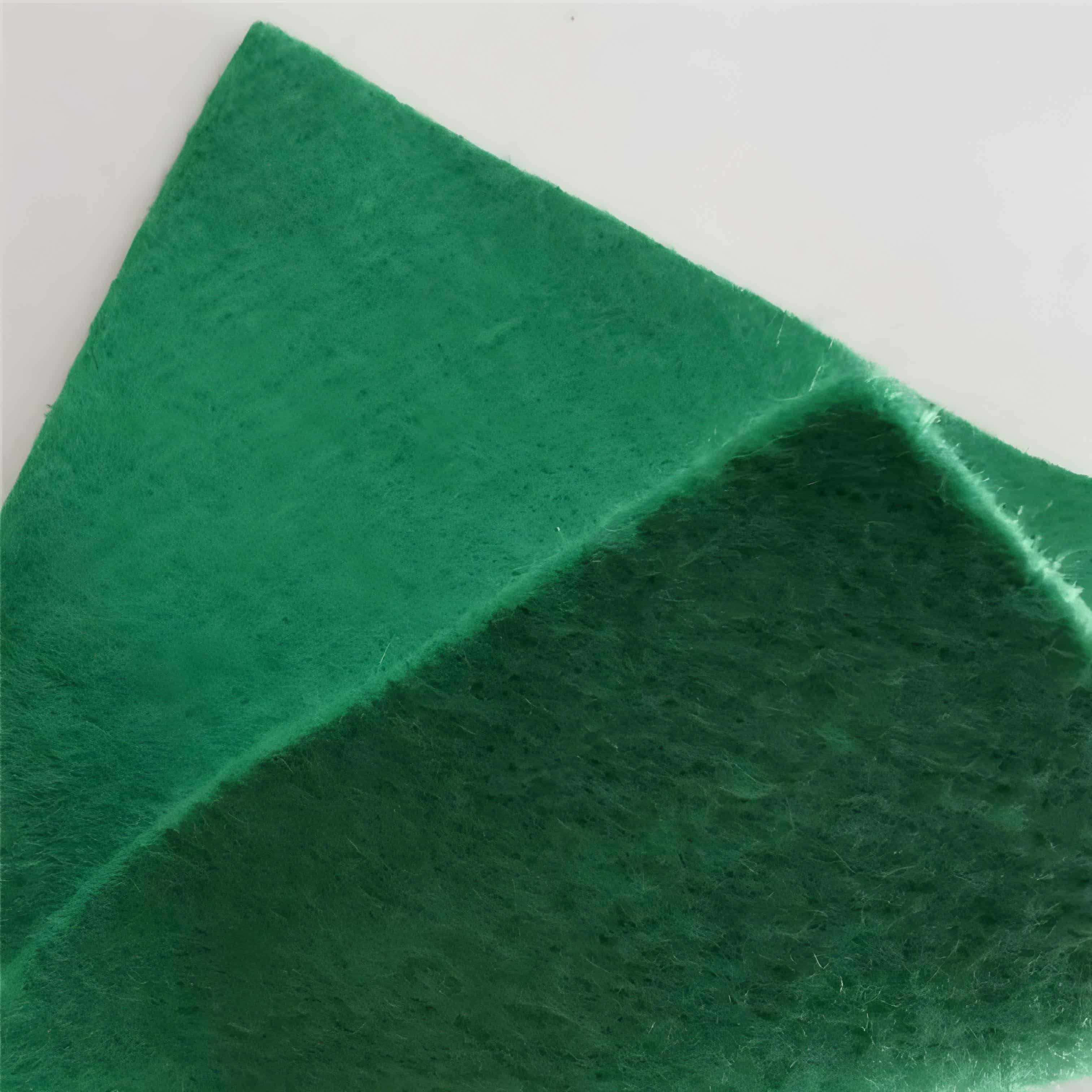

Process: The fibers (short fibers or long fibers) are randomly oriented or laid out, and then consolidated through mechanical entanglement (needle punching), thermal bonding, or chemical bonding. Among them, needle punched non-woven fabric is the most common.

Features: It looks like felt, fluffy and porous, has good water permeability, and is isotropic (with similar performance in all directions).

Main applications: Focusing on filtration, drainage, isolation, and protection functions.

Knitted geotextile:

Process: The yarn is connected together using a warp knitted coil structure.

Characteristics: Relatively few applications, combined with some characteristics of spinning and non-woven.

Process: Combine two or more different types of geotextiles (such as woven and non-woven) or geotextiles with other geosynthetic materials (such as geomembranes, geogrids).

Feature: Achieving complementary and enhanced functionality. For example, "non-woven fabric+geomembrane" has both the drainage protection function of non-woven fabric and the anti-seepage function of geomembrane.

3. Key performance indicators

Physical properties: Mass per unit area (g/m ²), thickness (mm).

Mechanical properties: tensile strength, elongation at break, tear strength, burst strength, grip strength, friction coefficient.

Hydraulic performance:

Porosity: The ratio of pore volume to total volume.

Equivalent aperture: a key indicator that characterizes the filtration performance of geotextiles, represented by O ₉₀ or O ₉₅, indicating that 90% or 95% of the apertures are smaller than this value.

Vertical permeability coefficient: characterizes the vertical permeability capacity.

Hydraulic conductivity/plane permeability coefficient: characterizes the ability to transport water flow within its own plane.

Durability: UV resistance, chemical corrosion resistance, biodegradation resistance, creep resistance.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and railway engineering

In roadbed construction, laying geotextile between the roadbed and the pavement base can isolate soil materials of different materials (such as preventing fine soil from mixing into the sand and gravel base), avoiding the base from losing strength due to soil mixing; At the same time, it can discharge the accumulated water in the roadbed, reduce the erosion of rainwater on the roadbed, and extend the service life of the road.

2. Water conservancy and flood control engineering

In the construction of embankments for rivers and reservoirs, geotextiles can be laid on the upstream slope of the embankment or inside the dam body to play a filtering role: allowing water infiltration, preventing soil particles from flowing away with water, and preventing the embankment from experiencing pipe surges and collapses;

During flood prevention, it can also be used as an auxiliary layer to quickly build temporary water barriers and enhance the waterproof effect.

3. Construction and Municipal Engineering

In the foundation construction of underground garages and building basements, geotextiles are laid between the waterproof layer and the soil to protect the waterproof layer from sharp stones and soil scratches, while assisting in the discharge of moisture from the foundation;

In the slope treatment of urban green belts and artificial lakes, soil can be fixed to prevent soil erosion, and vegetation planting can also be used to improve slope stability.

4. Environmental Protection and Ecological Engineering

In the construction of landfill sites, geotextile is used as a protective layer for the anti-seepage system, laid on top of the anti-seepage membrane to prevent sharp objects in the garbage from puncturing the anti-seepage membrane and prevent leachate from polluting groundwater sources;

In mining reclamation and soil remediation projects, geotextiles are used to isolate contaminated soil from normal soil, while helping to remove excess water from the soil, creating conditions for vegetation restoration.

5. Tunnels and Underground Engineering

In tunnel construction (such as shield tunnels), geotextile is often used in combination with waterproof boards, laid between the tunnel lining and the surrounding rock, which can filter out water seepage from the surrounding rock, prevent sediment from blocking drainage channels, and buffer the pressure of the surrounding rock to protect the waterproof board.

Geotextile, as a key geosynthetic material, has become an indispensable part of modern civil engineering due to its excellent reinforcement, isolation, filtration, drainage, and protective functions. From highways to environmental protection projects, it silently enhances the safety, durability, and economy of engineering, and is an outstanding representative of modern engineering technology progress.