Subgrade Enhancement Geotextile

1.Stable roadbed: Fiber mesh disperses loads, reduces soil displacement, prevents roadbed settlement and deformation, and is more suitable for soft soil foundation.

2.Damage resistance: Strong tensile strength, stretchability, stress absorption, crack prevention, and can withstand mechanical compaction and stone friction.

3.Cost saving and good construction: Directly laid between soil layers, flexible cutting without waste; 40% faster than traditional methods, saving 20% -30% of costs per kilometer.

4.Environment resistance: Anti-aging, acid-base resistance, can be used from -40 ℃ to 60 ℃, and is not afraid of rain blisters and soil corrosion. It is also durable in harsh road sections.

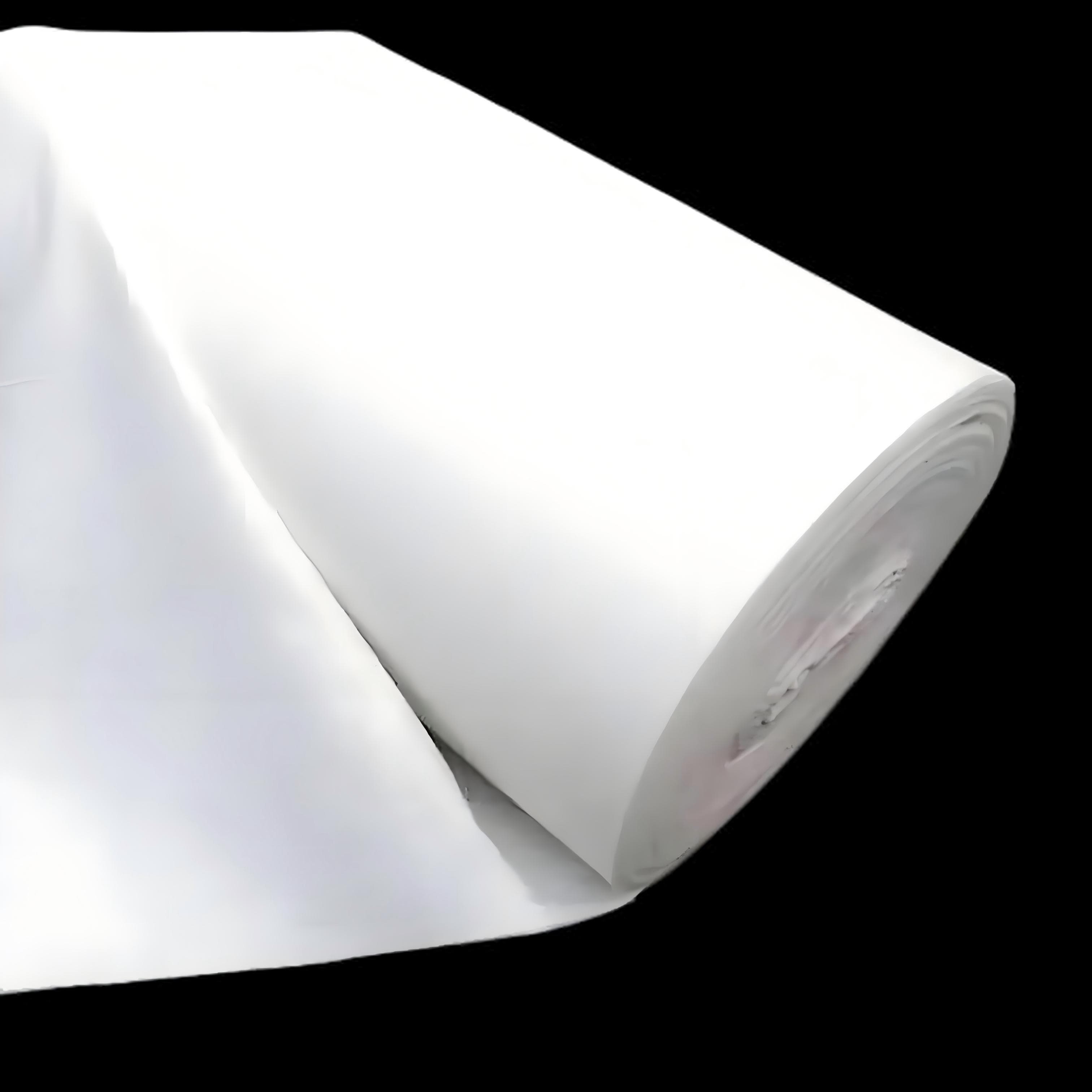

Product Introduction

Basic Properties

Material: Subgrade Enhancement Geotextile are made from high-strength fibers such as polyester and polypropylene through special processes, with inherent anti-aging and acid-alkali resistance properties.

Form: Mostly in roll form (width adapted to subgrade construction requirements), which can be flexibly cut. The thickness and tensile strength can be customized according to needs.

Application Scenarios: Mainly used for subgrade reinforcement in infrastructure projects such as highways, railways, and municipal roads, especially suitable for sections with soft soil foundations, rainy areas, or saline-alkali soils.

Core Functions

Subgrade Stabilization: Through the fibrous network structure, subgrade geotextile disperses the loads caused by vehicle rolling and the self-weight of the soil layer, reduces the displacement of soil particles, and prevents subgrade settlement and deformation.

Crack Resistance and Protection: Relying on high tensile strength and ductility, subgrade geotextile absorbs the stress generated by temperature changes of the subgrade and uneven settlement of the foundation, avoids crack formation, and at the same time resists friction damage from construction machinery and stones.

Main Features

Convenient Construction: No complex processes are required; Stabilization geotextile fabric can be directly laid between subgrade soil layers or on the surface. Stabilization geotextile fabric can be flexibly cut without material waste, and the construction efficiency is 40% higher than that of traditional reinforcement methods.

Controllable Cost: The construction cost per kilometer is 20%-30% lower than that of traditional methods such as sand and gravel replacement. No frequent maintenance is needed in the later stage, reducing long-term investment.

Environmental Resistance: subgrade stabilization geotextile can be used stably in environments ranging from -40℃ to 60℃, is not afraid of rainwater immersion and soil corrosion, and has a long service life in harsh road sections.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Highway Subgrade Engineering

Soft Soil Foundation Sections: In the construction of highway soft soil foundations, subgrade enhancement geotextile are laid between the soft soil and the cushion layer (e.g., sand-gravel layer). Through their fibrous network structure, they disperse the loads from the upper subgrade and vehicles, reduce the displacement of soft soil particles, and prevent road surface depressions and cracks caused by soft soil settlement. They are especially suitable for high-grade highways (such as expressways and first-class highways) that have high requirements for subgrade stability.

Junction of Filled Subgrades: When the filled subgrade of a highway is connected to the original ground or bridge abutments, cracks are likely to occur due to uneven settlement. Laying geotextiles can enhance the integrity of the joint area, absorb the stress caused by settlement differences, prevent longitudinal cracks at the joints, and ensure the smoothness of the road surface.

2.Railway Subgrade Engineering

High Filled Subgrades: High filled subgrades of railways (e.g., filling height exceeding 5 meters) have large self-weight, which easily leads to compression and deformation of the underlying soil layer. During the layered construction of filling, a layer of subgrade geotextile is laid at certain intervals. This can disperse the weight of the fill, reduce the compression of the soil layer, avoid overall settlement of the subgrade, ensure the smoothness of railway tracks, and prevent jolting during train operation.

Sections in Wind-Sand/Saline-Alkali Areas: When building railways in wind-sand or saline-alkali areas, the subgrade is prone to erosion by wind and sand and corrosion by saline-alkali soil. The anti-aging and acid-alkali resistance properties of subgrade geotextile can resist environmental damage. At the same time, their network structure can block wind and sand from entering the interior of the subgrade, prevent damage to the subgrade structure, and extend the service life of the railway subgrade.

3.Municipal Road Engineering

Urban Arterial Roads and Express Roads: Urban arterial roads and express roads have large traffic volumes, and repeated vehicle loads easily cause fatigue deformation of the subgrade. Laying subgrade stabilization geotextile can enhance the fatigue resistance of the subgrade, reduce the displacement of soil particles caused by vehicle rolling, avoid ruts and cracks on the road surface, reduce the frequency of later maintenance, and ensure the efficiency of road traffic.

Subgrades Around Underground Pipelines: Underground pipelines (such as water supply, drainage, and gas pipelines) are often laid under municipal roads. The subgrades around the pipelines are prone to settlement due to soil disturbance. When backfilling soil after pipeline laying, subgrade stabilization geotextile are laid around the pipelines. This can fix the backfilled soil particles, prevent settlement of the subgrade around the pipelines caused by soil loss, and protect the safety of the pipelines.

4. Subgrade Engineering in Special Scenarios

Subgrades in Rainy Areas: Subgrades in rainy areas are easily softened by rainwater immersion, resulting in reduced bearing capacity. Stabilization geotextile fabric can block direct scouring of the subgrade soil by rainwater, while allowing excess water in the soil to drain out. This maintains the stability of the subgrade soil structure and prevents subgrade landslides and settlement caused by rainwater immersion.

Airport Runway Subgrades: Airport runways have extremely high requirements for subgrade flatness and stability; even slight settlement may affect the safety of aircraft takeoff and landing. Laying stabilization geotextile fabric in the construction of runway subgrades can strengthen the overall bearing capacity of the subgrade, reduce soil compression and deformation, ensure long-term flatness of the runway, and meet the load requirements of aircraft takeoff and landing.

From highways and railways to municipal roads, and to special scenarios such as rainy areas, wind-sand areas, and saline-alkali areas, subgrade reinforcement subgrade geotextile always play a role around the core goal of "stabilizing the subgrade and resisting risks". Whether it is solving the settlement of soft soil foundations, the deformation of high filled subgrades, or dealing with environmental erosion and soil disturbance around pipelines, they can rely on their characteristics of load dispersion, crack resistance and protection, and adaptation to complex environments to guarantee the subgrade quality of various infrastructure projects. They not only reduce the later maintenance costs but also ensure the long-term safety and efficient operation of transportation facilities, making them a key material in the field of subgrade reinforcement.