Geotextile Fabric for Muddy Roads

1. Reinforcement and load lifting: Enhance road bearing capacity, disperse load to prevent sinking vehicles, and adapt to heavy vehicle traffic.

2. Drainage and mud isolation: Quickly drain accumulated water to reduce moisture content, isolate mud and prevent slipping, and maintain road stability.

3. Wear resistance and corrosion resistance: resistant to rolling and abrasion, moisture and corrosion, long service life, and reduced replacement.

4. Easy to lay and flexible: easy to cut, suitable for complex road surfaces, fast construction, and adaptable to emergency and long-term scenarios.

Products Introduction:

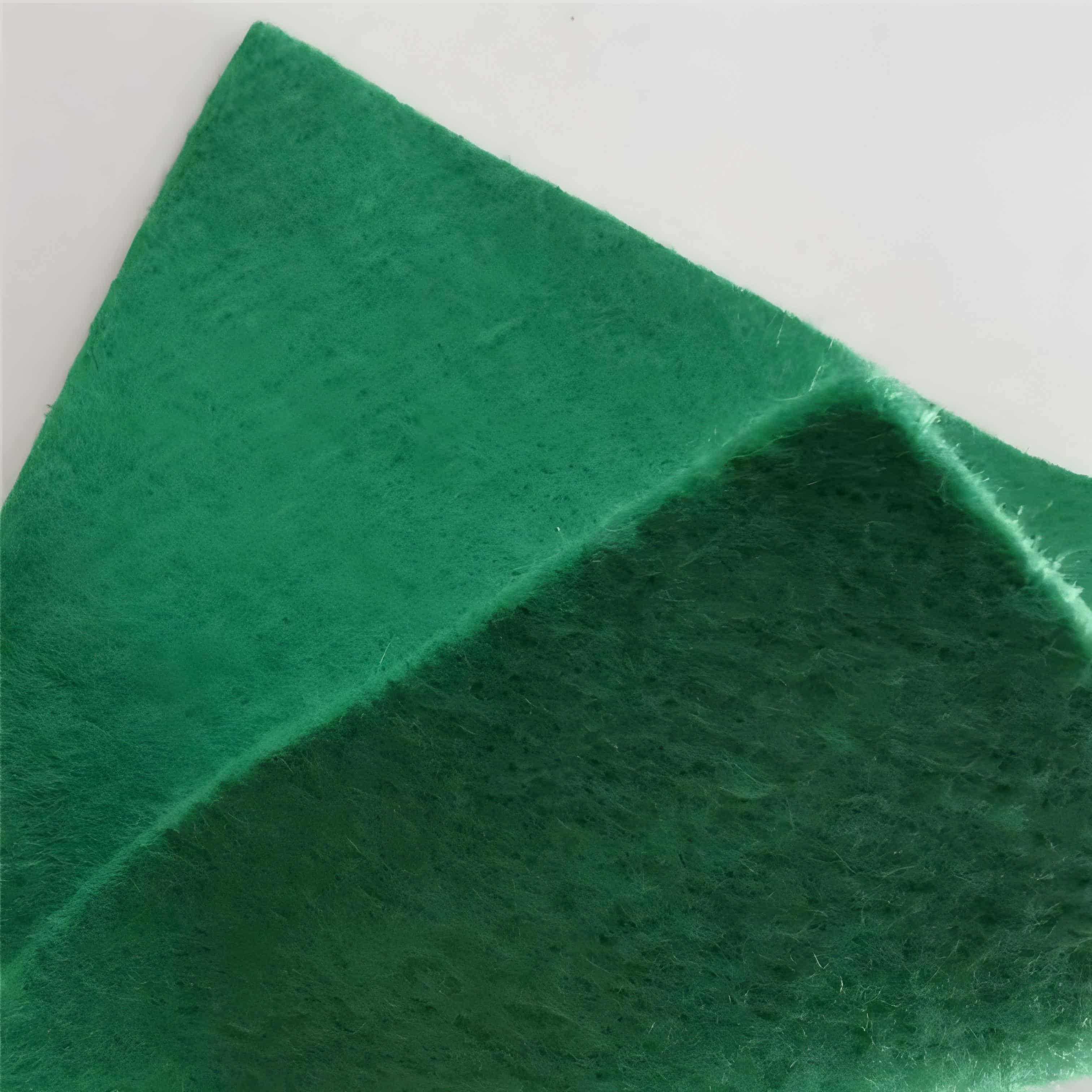

Geotextile Fabric for Muddy Roads is a functional geosynthetic material designed specifically to improve the traffic conditions on muddy roads. It is made from polypropylene (PP) or polyester (PET) and processed through needle punched non-woven or machine weaving techniques. Some products are treated for wear and corrosion resistance. Its core function is to lay on the surface or subgrade of muddy roads, and through the triple function of "reinforcing load-bearing, drainage and mud isolation, and stabilizing the subgrade", solve the problems of vehicle sinking and road surface damage caused by muddy soil and insufficient bearing capacity, and quickly improve the road capacity and durability. This product is suitable for muddy scenes such as rural dirt roads, temporary construction access roads, and mining area roads. Compared with traditional sand and gravel paving, it has the advantages of low cost, fast effectiveness, and easy maintenance. It is an ideal material for emergency improvement and long-term maintenance of muddy roads.

Product Features:

1. Strong reinforcement to enhance load-bearing capacity: Adopting a high-strength fiber interwoven structure, the longitudinal/transverse tensile strength reaches 15-40kN/m, and the tear resistance performance is outstanding. After laying, it forms a "composite load-bearing layer" with the road base, which can disperse vehicle loads (especially heavy vehicles such as agricultural machinery and trucks), significantly improve the bearing capacity of muddy roads (can increase the bearing capacity by 50% -80%), effectively prevent vehicles from getting stuck in mud, and reduce the marks and depressions caused by rolling on the road surface.

2. Drainage and mud isolation, moisture control and anti sinking: The fabric pore design is scientifically designed (0.1-0.3mm), with both "isolation" and "drainage" functions - it can isolate the surface muddy soil from the vehicle tires, preventing soil from adhering to the tires and causing slippage; At the same time, quickly discharge the surface water of the road (permeability coefficient ≥ 1 × 10 ⁻ cm/s), reduce the soil moisture content, avoid the road from being continuously muddy due to accumulated water, maintain the stability of the roadbed structure, especially suitable for muddy sections with heavy rain or high groundwater levels.

3. Wear resistant and corrosion-resistant, suitable for harsh environments: The surface has been treated with special technology, with excellent wear resistance and can withstand long-term vehicle rolling and sharp stone friction; Simultaneously resistant to acid and alkali, and resistant to microbial corrosion, it can be used stably in wet and organic environments on muddy roads, with a service life of 3-8 years, reducing the trouble of frequent replacement.

4. Lightweight and easy to lay, flexible and adaptable: The texture is flexible and lightweight (150-300g/m ²), and can be flexibly cut according to the width and length of the road, fitting irregular road surfaces (such as potholes and sloping sections); Laying can be quickly completed without the need for heavy equipment, manual labor or small machinery, and can even be temporarily laid to meet emergency traffic needs. The construction efficiency is increased by more than 60% compared to traditional road repair methods.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Rural Muddy Soil Road Renovation: Lay in muddy soil roads such as rural field roads and village group connecting roads, directly covering the surface soil or laying under the gravel base. Through reinforcement and drainage functions, solve the problem of sinking agricultural vehicles and private cars when passing through, and ensure the safety of agricultural product transportation and villagers' travel during the rainy season.

2. Temporary construction access road: a temporary road used for construction sites and mining areas, laid on soft foundations or muddy areas, quickly forming a temporary road surface for construction machinery and transportation vehicles to pass through, avoiding the impact of muddy roads on construction progress, and can be recycled and reused after the project is completed.

3. Scenic area trails and pasture roads: Used in the access roads of scenic area forest trails and ecological pastures, it not only maintains the cleanliness of the road surface through the function of mud separation, but also facilitates the passage of tourists or herds; It can also protect surface vegetation, reduce the damage of vehicles to the ecological environment, and balance practicality and ecology.

4. Emergency relief roads: emergency roads are paved in muddy roads after floods, rainstorm and other disasters to quickly restore the traffic capacity of rescue vehicles and material transport vehicles, so as to buy time for disaster relief work, especially suitable for temporary traffic support in disaster areas.

Geotextile Fabric for Muddy Roads focuses on the core pain points of muddy roads, with the core advantages of "reinforced loading, drainage and mud isolation, wear resistance, and easy construction", providing efficient and economical solutions for various muddy road sections. Whether it is the daily traffic guarantee of rural roads or the temporary traffic demand in construction areas, rapid laying can significantly improve road carrying capacity and traffic capacity, while reducing maintenance costs. The product has both acute and long-term responsiveness, capable of meeting short-term traffic needs and supporting long-term use. It is an ideal choice for improving muddy road conditions and enhancing traffic efficiency, providing reliable road support for rural revitalization, engineering construction, and emergency support.