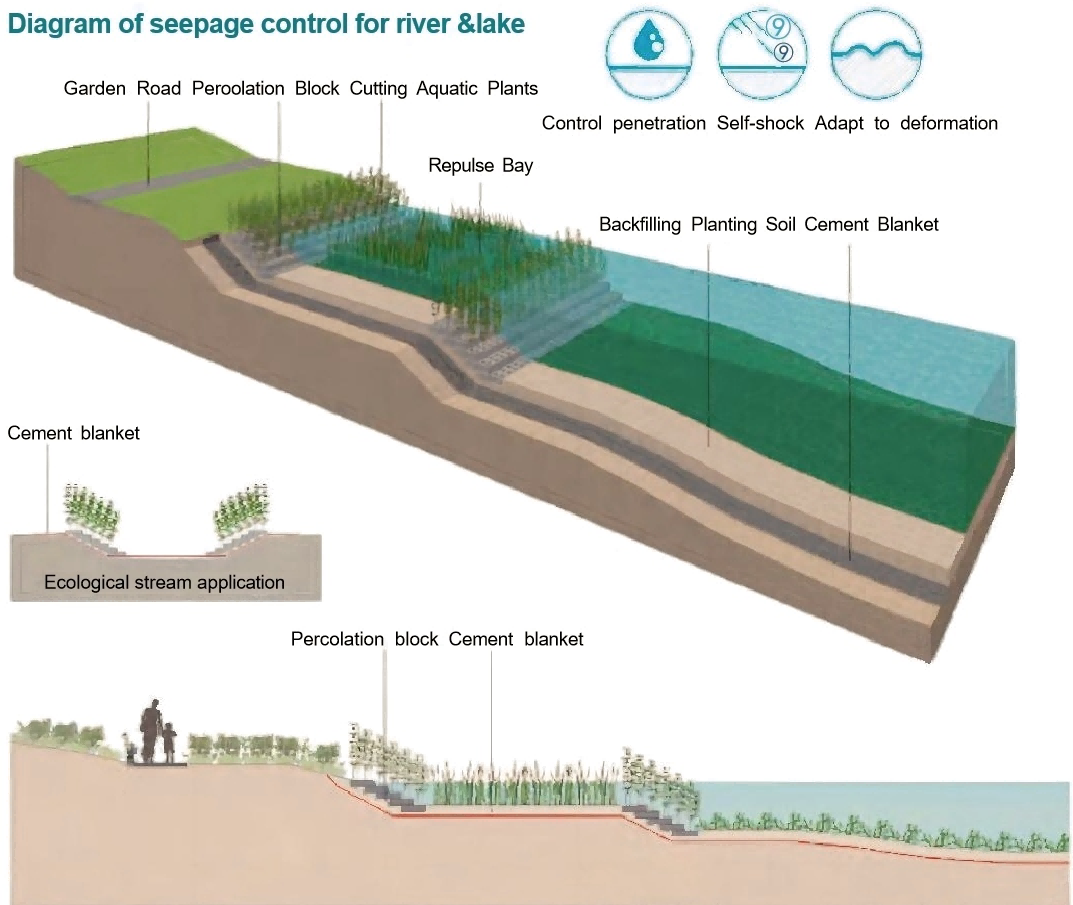

Using Cement Impregnated Fabric in Coastal Areas: Saltwater Corrosion Prevention and Wave Resistance

Coastal environments current relentless challenges for building materials, with saltwater corrosion, effective waves, and harsh climate threatening structural integrity. Cement impregnated cloth has emerged as a durable, versatile answer for coastal projects, presenting excellent resistance to saltwater harm and wave impact. Whether in search of concrete material close to me for a small shoreline restore or sourcing concrete material for sale for large-scale coastal protection, this fabric outperforms usual preferences in adaptability and longevity. This information explores how cement impregnated material excels in coastal settings, its saltwater corrosion prevention mechanisms, wave resistance capabilities, and key issues for resolution and application.

Cement Impregnated Fabric: Core Advantages for Coastal Applications

Cement impregnated fabric—also acknowledged as concrete cloth—is a geosynthetic fabric consisting of a bendy material matrix saturated with dry cementitious compounds. When activated via water, it treatment options into a robust, water resistant concrete layer that adheres to irregular surfaces, making it perfect for the uneven terrain of coastal areas. Unlike inflexible concrete, its pre-cure flexibility permits for effortless set up round rocks, pilings, and shoreline contours—a indispensable advantage for coastal projects. For these looking out for concrete fabric close to me, its light-weight and convenient transportability suggest it can be deployed in faraway coastal places besides heavy machinery. When sourcing concrete fabric for sale, coastal task managers prioritize editions engineered for saltwater resistance, as this ensures the cloth continues power and structural integrity in opposition to corrosive marine environments. Cement impregnated fabric’s special homes bridge the hole between flexibility and durability, fixing frequent coastal building ache points.

Saltwater Corrosion Prevention: How Cement Impregnated Fabric Endures Marine Environments

Saltwater corrosion is a major chance to coastal structures, as sodium chloride and different marine salts penetrate standard materials, inflicting cracking, spalling, and structural failure. Cement impregnated cloth mitigates this danger via its dense, low-porosity shape and specialised formulations. The material matrix therapies into a tight concrete layer that minimizes saltwater infiltration, blockading corrosive ions from attaining the substrate. Many cement impregnated fabric designed for coastal use consist of corrosion-inhibiting admixtures, which neutralize the outcomes of salt and forestall inside degradation. Unlike steel-reinforced concrete, which is susceptible to rust-induced enlargement in saltwater, cement impregnated material depends on its personal fiber reinforcement, casting off metallic corrosion risks. For house owners and contractors looking out for concrete material close to me for coastal repairs, verifying these anti-corrosion residences is essential. When buying concrete fabric for sale, seem to be for merchandise examined in marine environments to make sure long-term resistance to saltwater damage.

Wave Resistance: Protecting Coastal Structures with Cement Impregnated Fabric

Coastal constructions face regular assault from waves, storm surges, and water turbulence, requiring substances that can take in influence and withstand erosion. Cement impregnated material offers notable wave resistance via its cured power and bendy installation. Once hydrated, it types a tough, abrasion-resistant barrier that dissipates wave energy, decreasing scouring and erosion alongside shorelines, seawalls, and jetties. Its capacity to conform to the herbal contour of the coast creates a seamless shielding layer that redirects wave pressure barring cracking—unlike inflexible concrete, which frequently fails beneath repeated impact. For tasks the usage of cement impregnated material as a defensive layer over current structures, it reinforces susceptible factors and extends the lifespan of seawalls and breakwaters. Those looking for concrete material close to me for emergency storm harm restore will recognize its speedy curing time, which permits for rapid deployment to mitigate in addition wave-induced damage. When deciding on concrete fabric for sale for wave-prone areas, decide for thicker variations with excessive tensile power to maximize have an effect on resistance.

Key Applications of Cement Impregnated Fabric in Coastal Areas

1. Shoreline Erosion Control

Coastal erosion is a power issue, and cement impregnated material offers an tremendous answer for stabilizing shorelines. It can be hooked up alongside beaches, river mouths, and coastal bluffs to create a defensive layer that traps sediment and resists wave scouring. For these looking for concrete fabric close to me for small-scale erosion control, it can be reduce to measurement and utilized to prone areas except disrupting nearby ecosystems. When sourcing concrete fabric for sale for giant shoreline projects, it is regularly used in conjunction with rock or gravel to create composite erosion barriers. Cement impregnated fabric’s potential to combination with herbal environment makes it a desired preference for eco-sensitive coastal areas, as it preserves habitat whilst stopping erosion.

2. Seawall and Breakwater Repair/Reinforcement

Existing seawalls and breakwaters regularly go through from saltwater harm and wave impact, and cement impregnated material presents a cost effective restore solution. It can be wrapped round broken sections, cured in place, and built-in with the authentic shape to restoration power and stop in addition deterioration. Contractors looking for concrete fabric close to me cost its ease of installation, which minimizes downtime and labor costs. When buying concrete material for sale for seawall reinforcement, its corrosion resistance ensures the restore lasts in harsh marine conditions. Unlike ordinary concrete repairs, which require full-size formwork, cement impregnated cloth conforms to the form of the structure, growing a seamless, long lasting bond.

3. Coastal Infrastructure Protection

Cement impregnated cloth is used to shield necessary coastal infrastructure, consisting of piers, docks, and bridge foundations. It shields these constructions from saltwater corrosion and wave impact, extending their operational lifespan. For tasks requiring concrete fabric close to me for infrastructure maintenance, it can be utilized to pilings and substructures to create a shielding barrier in opposition to marine organisms and corrosive salts. When choosing concrete material for sale for infrastructure projects, high-strength variations are favored to face up to heavy masses and steady wave action. Its water-resistant homes additionally stop water infiltration into concrete foundations, decreasing the hazard of freeze-thaw injury in coastal areas with fluctuating temperatures.

Tips for Selecting and Installing Cement Impregnated Fabric in Coastal Areas

When deciding on cement impregnated cloth for coastal projects, begin through verifying its marine-grade certification—this ensures it is formulated for saltwater resistance. For these looking for concrete material close to me, seek advice from nearby suppliers with trip in coastal applications, as they can propose merchandise tailor-made to regional stipulations (e.g., excessive wave energy, severe salt exposure). When buying concrete fabric for sale, prioritize substances with UV resistance, as coastal areas have extreme daylight that can degrade inferior fabrics. During installation, make sure the substrate is smooth and free of salt deposits to promote perfect adhesion. Hydrate the material with freshwater (not saltwater) to make sure full curing, and guard the curing fabric from wave motion till it reaches most strength. For fantastic results, work with contractors skilled in cement impregnated cloth set up in coastal environments, as desirable approach is indispensable for maximizing performance.

Conclusion: Cement Impregnated Fabric as a Coastal Protection Staple

Cement impregnated material has mounted itself as an fundamental cloth for coastal building and protection, imparting unbeatable saltwater corrosion resistance and wave have an effect on tolerance. Whether looking out for concrete fabric close to me for a residential shoreline restore or sourcing concrete material for sale for large-scale infrastructure projects, it grants durability, flexibility, and ease of installation. Its potential to face up to the cruelest marine conditions—from saltwater corrosion to effective storm waves—makes it a most efficient choice to standard materials. By appreciation its core advantages, applications, and set up satisfactory practices, coastal undertaking managers and householders can leverage cement impregnated material to create resilient, long-lasting constructions that stand up to the challenges of coastal environments.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province