Geotextiles Fabric

1. Improve engineering stability: By reinforcing and separating, reduce soil displacement, avoid mixing materials of different particle sizes, and extend the service life of structures such as roads and dams.

2. Reduce construction costs: There is no need to use traditional heavy materials such as sand and gravel cushion layers, reducing excavation and transportation costs, while simplifying the construction process and shortening the construction period.

3. Environmentally friendly and durable: synthetic fiber geotextile is acid and alkali resistant, corrosion resistant and aging resistant, and can be used for a long time in harsh environments.

4.Controllable permeability: Depending on the process, geotextiles can achieve "filtration permeability" or "impermeability" to meet the hydrological needs of different projects.

Product Introduction:

Geotextiles Fabric is a sheet-like material made from synthetic fibers such as polyester and polypropylene, or natural fibers such as jute, processed through processes such as needle punching, weaving, thermal bonding, and spunbonding. It can combine with engineering media such as soil, rock, and water, and play specific functions in engineering through its own physical properties and structural characteristics. It is an important auxiliary material for improving engineering stability and extending service life.

Main characteristics of geotextile

The characteristics of geotextiles vary depending on the manufacturing process, and the mainstream types can be divided into the following categories:

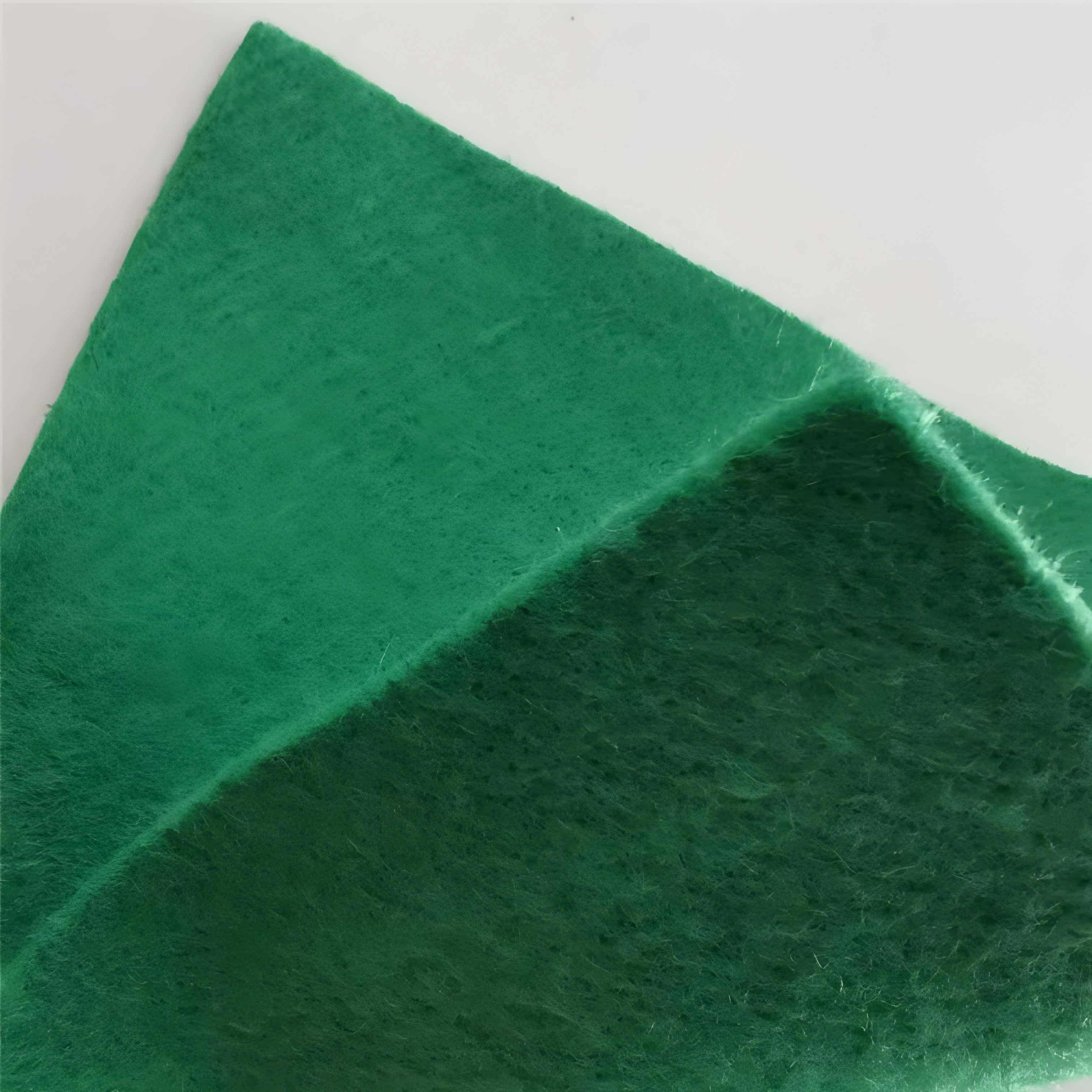

1. Non woven geotextile (mainly using needle punching and thermal bonding processes): The fibers are randomly arranged, with excellent water permeability and filtration properties. The texture is soft and closely adheres to the soil surface, with relatively low cost. It can quickly remove excess water from the soil and prevent the loss of fine soil particles.

2. Woven geotextile (mainly interwoven with warp and weft yarns): has a tight and regular structure, high tensile strength, low elongation, strong stability, and can withstand large longitudinal and transverse tensile forces. It performs outstandingly in scenarios that require high-strength support.

3. Knitted geotextile (mainly using yarn coil hooking technology): good elasticity, strong puncture resistance, light weight and high flexibility, can adapt to slight soil deformation, and is not easily damaged due to excessive local stress.

4. Composite geotextile (composed of non-woven fabric, woven fabric, geomembrane, etc.): It has multiple functions, such as "filtration of non-woven fabric+reinforcement of woven fabric", "permeability of non-woven fabric+impermeability of geomembrane", and can meet complex engineering needs.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road and railway engineering

Roadbed separation and reinforcement: Lay geotextile between the roadbed and the base layer to prevent soil particles from mixing into the base layer with rainwater or vehicle loads, avoiding loose base structure and decreased bearing capacity; At the same time, the tensile performance of geotextile can disperse the stress on the roadbed, reduce roadbed settlement and cracking, especially suitable for soft soil foundation sections.

Road drainage: Lay non-woven geotextiles with good permeability under blind ditches and road shoulders on both sides of the road to quickly drain rainwater or groundwater inside the roadbed, prevent long-term water accumulation and softening of the roadbed, and avoid problems such as potholes and frost heave on the road surface; Used below the bridge deck pavement layer, it can also isolate the erosion of the bridge structure caused by water seepage from the bridge deck.

Old road renovation: When adding new pavement on old asphalt or cement pavement, laying geotextile can alleviate the settlement difference between the old and new pavement, reduce reflection cracks, and lower maintenance costs after renovation.

2. Water conservancy and waterway engineering

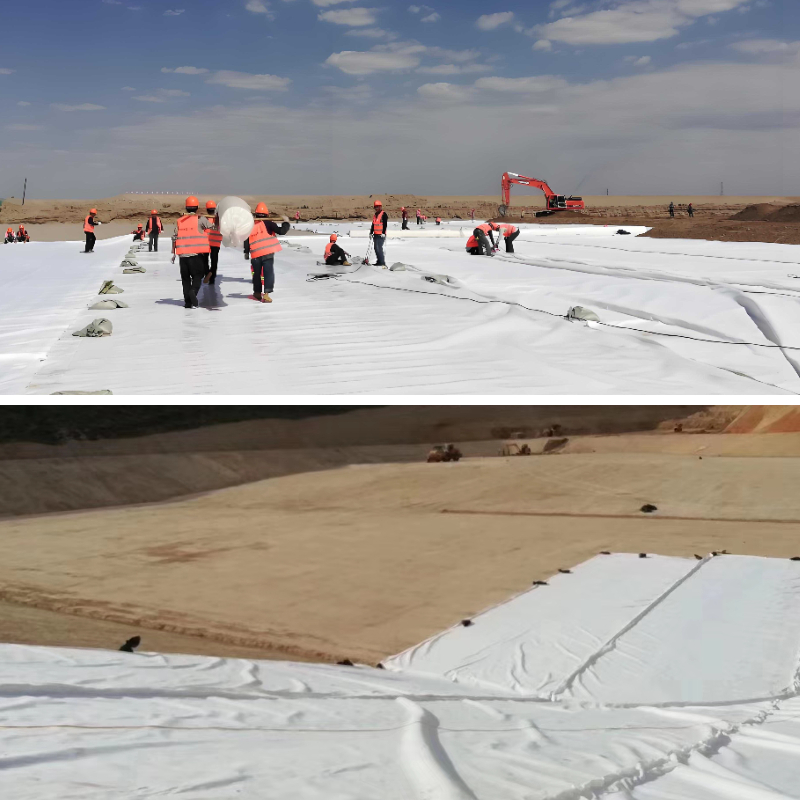

Dam protection and filtration: Lay geotextile (often combined with geomembrane) on the surface of the upstream slope of the dam to resist the erosion of waves and water flow on the soil of the dam and prevent soil erosion; Lay around the anti-seepage wall or drainage body inside the dam as a filter layer, allowing the seepage of the dam body to be discharged while blocking the loss of soil particles, avoiding the risk of pipe surge and collapse of the dam body.

River and channel management: Lay geotextile on the slope and bottom of the river channel, and use materials such as ecological bags and gabion nets to reinforce the slope and prevent collapse, while reducing the erosion of the riverbed by water flow; When used in irrigation channels, it can also reduce channel leakage and improve water resource utilization efficiency.

Port and dock construction: laying high-strength woven geotextile in the foundation of port yards and dock approach bridges to enhance the bearing capacity of the foundation and reduce foundation settlement caused by cargo or vehicle loads; Using it in the backfill soil area behind the breakwater can accelerate the drainage consolidation of the backfill soil and shorten the construction period.

3. Environmental Protection and Municipal Engineering

Landfill site: pollution prevention and leachate control: composite geotextiles are laid at the bottom and surrounding areas of the landfill site, with non-woven fabrics as a protective layer to prevent the geomembrane from being pierced by sharp debris from garbage, while filtering impurities in the leachate; Used in the top cover layer of a landfill site, it can accelerate the infiltration and discharge of rainwater, reduce the pressure of landfill gas caused by accumulated water, and isolate direct contact between garbage and surface soil.

Wastewater treatment and water environment management: Geotextile is laid at the bottom of sedimentation tanks and filter tanks in wastewater treatment plants as a filtering layer to intercept suspended solids in wastewater and improve filtration efficiency; In artificial wetlands and river ecological restoration projects, laying geotextiles can fix wetland soil or aquatic plant roots, prevent soil loss with water flow, and maintain the filtration and purification functions of wetlands.

Municipal greening and sponge city: laying geotextile under the planting layer of roof greening and urban park lawns, on the one hand as a drainage layer, quickly draining excess rainwater and avoiding plant root rot; On the other hand, as an isolation layer, it prevents the planting soil from mixing with the roof waterproof layer or underground soil; Used under the permeable pavement in sponge cities, it can assist in filtering rainwater, reduce the blockage of permeable holes, and ensure the permeability of the pavement.

4. Mining and Energy Engineering

Management of mine tailings pond: laying geotextile at the bottom of the tailings pond as an anti-seepage and filtering layer to prevent heavy metal ions and toxic wastewater from seeping into the underground soil and groundwater, reducing environmental pollution; Laying during the process of tailings accumulation can reinforce the tailings pile in layers, reducing the risk of landslides and dam breaches in the tailings pond.

Photovoltaic and wind power engineering: laying geotextile in the support foundation area of the photovoltaic power station to reinforce the surface soil, prevent the support from tilting due to soil settlement, and ensure the installation accuracy of the photovoltaic panels; Using it around the wind power base can reduce soil erosion after base construction and isolate rainwater erosion on the base foundation.

Tunnel and underground engineering: Geotextile is laid between the secondary lining and initial support of the tunnel as a protective layer for the waterproof board to prevent sharp stones from the anchor layer from piercing the waterproof board. At the same time, it guides the seepage inside the tunnel to be discharged along the geotextile to prevent water leakage problems in the lining.

5. Agriculture and Ecological Engineering

Agricultural planting and greenhouse: laying geotextiles under the soil in the greenhouse to prevent underground pests from invading the crop roots upwards, while reducing secondary salinization caused by soil salinity rising with water content; Used in irrigation ditches in orchards and farmland, it can reduce soil erosion on the ditch walls and extend the service life of irrigation ditches.

Ecological slope restoration: In the ecological restoration of exposed slopes along highways, railways, or abandoned mining sites, geotextiles (often mixed with grass seeds and nutrient soil) are laid to fix the slope soil, provide a stable environment for plant growth, and prevent slope water and soil loss caused by rainwater erosion, accelerating vegetation recovery.