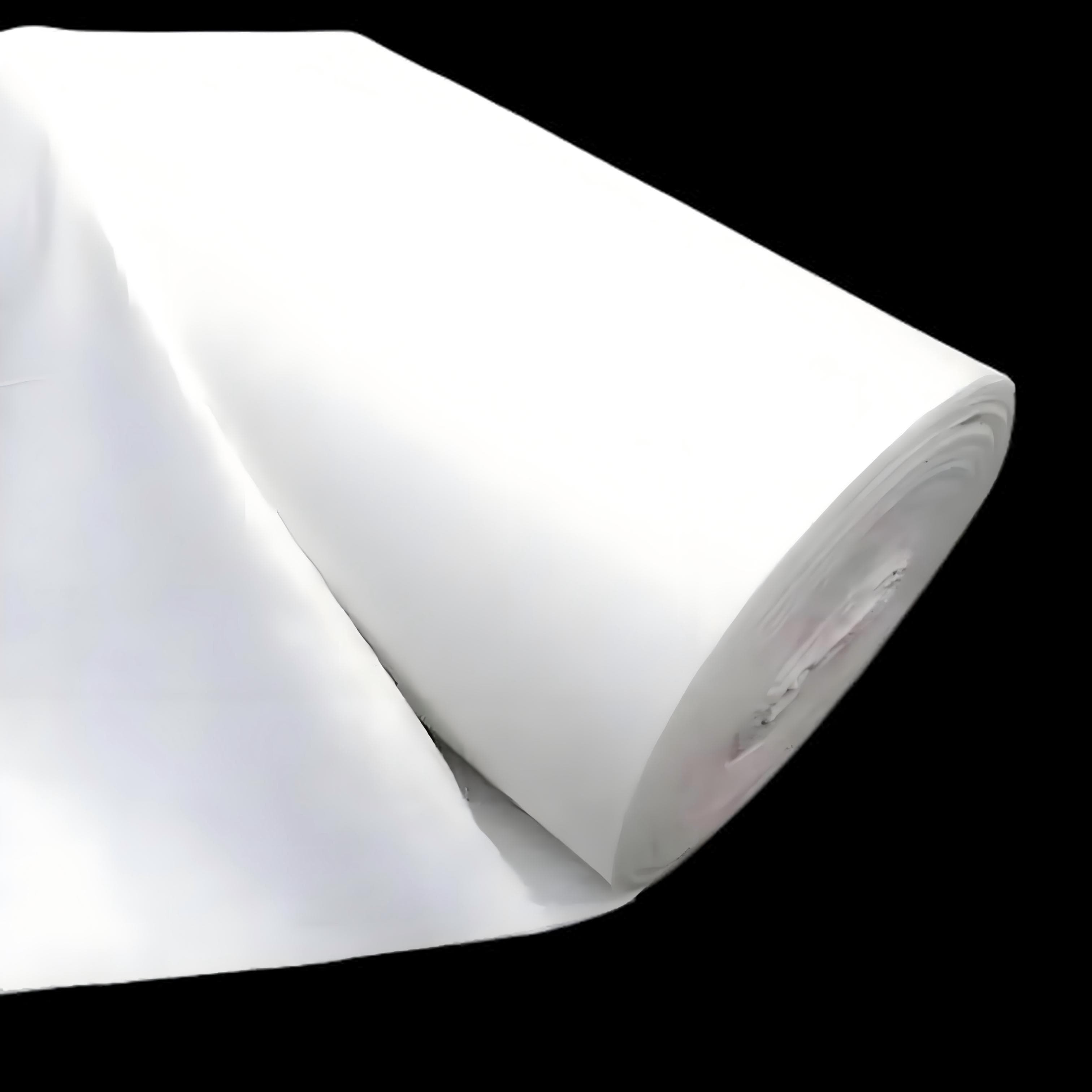

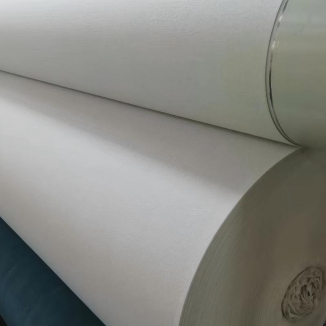

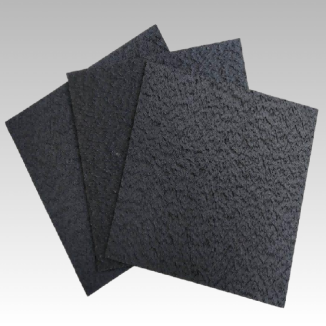

Geotex Fabric

1.Efficient filtration and drainage: The three-dimensional porous structure quickly guides water, intercepts fine soil to prevent blockage, and ensures smooth drainage.

2.Stable and damage resistant: The fibers are tightly interwoven, resistant to tension, elongation, and rolling, and the structure is stable for long-term use.

3.Scene adaptation: Flexible and easy to cut, suitable for complex terrain, compatible with multiple scenarios such as geotechnical and hydraulic engineering.

4.Economic convenience: Construction does not require large equipment, the cost is controllable, and the comprehensive cost-effectiveness is outstanding.

Products Introduction:

Geotex Fabric is a functional engineering material made from high molecular weight polymers (such as polypropylene, polyester, polyethylene, etc.) through processes such as non-woven, woven, and needle punched processing. Its core functions cover five dimensions: filtration, drainage, isolation, reinforcement, and protection. As a fundamental category of geosynthetic materials, it has been widely used in civil engineering as a key bridge for "material interlayer coordination+environmental protection" due to its lightweight, flexible, and durable characteristics. It is widely used in fields such as roads, water conservancy, environmental protection, and municipal engineering.

Compared with traditional engineering materials such as sand and concrete, Geotex Fabric focuses more on the combination of "functionality and ecology" - it can optimize the performance of engineering structures through physical effects, reduce resource consumption, and meet the needs of modern engineering for "efficiency, environmental protection, and low cost". It is an important material for promoting the lightweight and green development of civil engineering.

Product Features:

1. Functional composite, one material with multiple uses

It has multiple functions such as filtration, drainage, and isolation: as a filter layer, it can intercept soil fine particles to prevent blockage; as a drainage layer, it can quickly divert accumulated water; as an isolation layer, it can prevent the mixing of different materials, without the need for multiple materials to be stacked together, simplifying engineering design and construction processes, and adapting to multi process composite engineering scenarios.

2. Mechanically stable, resistant to damage and durable

The longitudinal and transverse fracture strength can reach 5-50kN/m (depending on the type), with excellent tear and tensile resistance, and can withstand the stress generated by heavy machinery compaction, water flow erosion, and soil displacement; After UV and acid-base treatment, the performance is stable in environments ranging from -30 ℃ to 80 ℃, with a service life of up to 5-20 years, reducing maintenance and replacement costs in the later stages.

3. Flexible and adaptable, with a wide range of scenarios

The texture is soft and has good extensibility, which can tightly adhere to irregular base layers such as slopes, ditches, and curved structures, without blind spots for laying; Lightweight (50-1000g/m ²), easy to cut, suitable for heavy-duty projects such as large dams and highways, as well as light projects such as courtyard renovation and small-scale water conservancy.

4. Eco friendly, permeable and breathable

Using non-toxic and harmless raw materials, the production process has no harmful emissions, and after laying, it does not pollute the soil and water bodies; The porous structure allows for the free infiltration of air and water, providing conditions for the growth of vegetation roots, and can directly cooperate with ecological greening projects to achieve synchronous promotion of "engineering protection+ecological restoration".

5. Economically efficient and easy to construct

The unit price of materials is lower than traditional protective materials, and construction does not require large equipment. It can be quickly laid manually, and the overlap width is ≥ 10cm to ensure integrity. The construction efficiency is 30% -50% higher than that of sand and gravel filter layers; The utilization rate of raw materials is high, and the comprehensive engineering cost can be reduced by 10% -20%.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Road subgrade: laid between the subgrade soil and graded crushed stone layer, isolating different soil materials to prevent mixing, while diverting accumulated water to avoid pavement cracking and settlement caused by subgrade softening, suitable for highway and rural road construction.

Bridge deck protection: used between the bridge deck pavement layer and the waterproof layer to filter impurities and prevent blockage of the waterproof layer, while buffering the impact of vehicle loads on the bridge deck and extending its service life.

2. Water conservancy and ecological engineering

River bank slope: laid on the surface of the bank slope or below the ecological gabion, intercepting soil particles to prevent erosion, and cooperating with vegetation planting to achieve ecological bank protection, suitable for small and medium-sized river management and wetland park construction.

Reservoir embankment: As an anti filter layer of the embankment, it isolates the soil and sand of the dam body, prevents fine soil loss from causing pipe surges, ensures the safety of the embankment, and is suitable for reservoir reinforcement and irrigation channel anti-seepage projects.

3. Environmental Protection and Waste Management Engineering

Landfill site: laid above the anti-seepage membrane at the bottom of the landfill site to filter impurities in the leachate and prevent blockages in the collection pipeline; Covering the surface of garbage, reducing dust and odors, suitable for domestic and industrial waste landfills.

Wastewater treatment: As a filter cloth for sedimentation tanks and filters in wastewater treatment plants, it intercepts suspended solids in wastewater, improves water quality, or is used for pre-treatment in reclaimed water reuse systems.

4. Municipal and Construction Engineering

Municipal Square/Parking Lot: Located between the ground base and surface layers, the isolation material layer prevents fine soil pollution, while also diverting rainwater to avoid ground depression and cracking, suitable for the construction of urban squares and residential parking lots.

Building foundation: Lay between the foundation cushion layer and the foundation soil to maintain the bearing capacity of the cushion layer, prevent uneven settlement of the foundation from causing cracking of the building wall, and adapt to residential and commercial building foundation treatment.

Geotex Fabric has the core advantages of "functional complexity, stability and durability, ecological adaptability, and economic efficiency", accurately solving the pain points of "material mixing, water erosion, ecological damage, and high cost" in civil engineering. Whether it is roadbed protection in transportation engineering, ecological shoreline protection in water conservancy engineering, or pollution prevention and control in the field of environmental protection, they can all provide reliable guarantees for the entire life cycle of the project through flexible performance combinations.

Compared to single functional materials, Geotex Fabric has achieved the application value of "multi effect integration", simplifying the construction process, reducing overall costs, and taking into account ecological and environmental protection needs. Its widespread application not only promotes the upgrading of engineering construction modes, but also provides important support for the development of green civil engineering, and is an indispensable basic functional material in modern engineering construction.