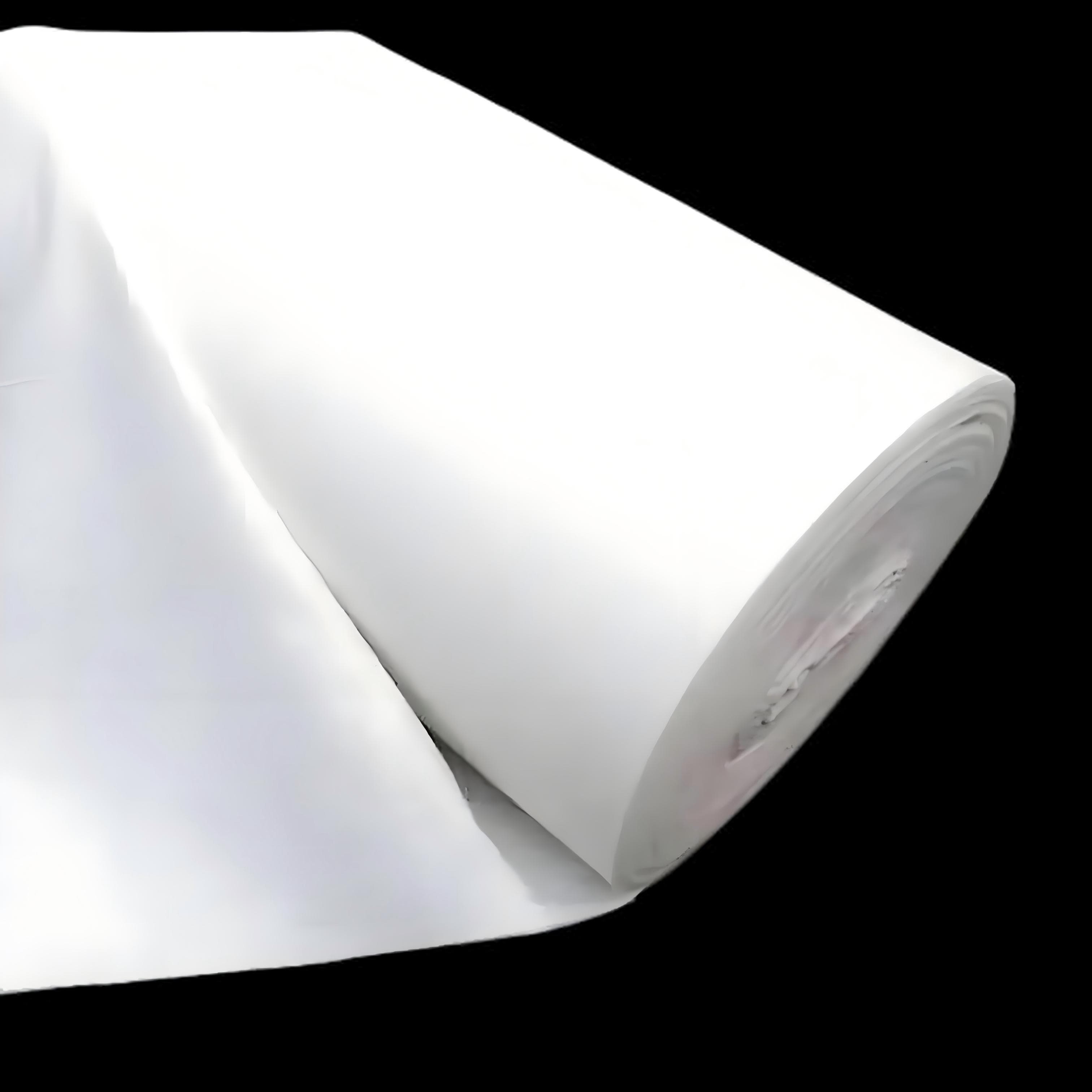

Geo Fiber Cloth

1. Improved Project Performance and Lifespan: Through its core function, geotextiles effectively prevent mixing of different soil layers, maintain long-term drainage, and enhance soil stability, significantly extending the service life of engineering structures such as roads and dams.

2. Convenient and Efficient Construction: Geotextiles are lightweight and supplied in rolls, making them easy to transport and lay, significantly accelerating construction schedules. This advantage is particularly evident in harsh geological conditions.

3. Durability: Made of synthetic fibers, geotextiles offer excellent resistance to chemical corrosion, microorganisms, and insect infestation, maintaining their performance over time in various soil and underground environments.

4. Environmental Protection: In applications such as slope protection and soil and water conservation, geotextiles effectively prevent soil erosion, promote vegetation growth, and contribute positively to the ecological environment.

Product Introduction:

Geo Fiber Cloth is a permeable geosynthetic material made of synthetic fibers (such as polypropylene, polyester, nylon, etc.) through needle punching or weaving processes. It is essentially a type of 'cloth', but is given the title of 'geotechnical' due to its specific function in civil engineering. Geotextile is one of the most widely used and fundamental materials in geotechnical engineering. It is usually supplied in the form of rolls and laid between or on the surface of soil, rock, or other geotechnical materials, serving functions such as reinforcement, protection, filtration, drainage, and isolation.

Core Features and Performance

The performance characteristics of geotextiles directly determine their application scope, and the main features include:

1. Physical properties:

Thickness and mass per unit area: This is the most basic technical indicator, usually expressed in grams per square meter, which directly affects its mechanical and hydraulic performance.

Porosity: refers to the percentage of pore volume in geotextile to the total volume, which is related to the permeability and soil retention of the material.

2. Mechanical properties:

Tensile strength: The ability of geotextiles to resist tensile failure under stress, which is crucial for reinforcement and strengthening applications.

Tear strength and burst strength: measures the ability of geotextiles to resist local concentrated loads (such as sharp edged stones) and reflect their durability during construction and use.

Friction characteristics: The friction coefficient between geotextile and upper and lower soil layers directly affects the stability of slopes, reinforced soil structures, etc.

3. Hydraulic performance:

Permeability (vertical permeability coefficient): The ability to allow water flow to pass vertically through its plane, which is the foundation of drainage and filtration functions.

Hydraulic conductivity (plane permeability coefficient): The ability to transport water flow within its own plane, which is particularly important for forming a horizontal drainage layer.

Durability:

Including resistance to UV aging, chemical corrosion, and biodegradation, ensuring that its functionality does not significantly deteriorate within the designed service life.

Main types and their characteristics

According to different manufacturing processes and structures, geotextiles are mainly divided into the following categories:

Manufacturing process: Short fibers or long fibers are combed into a net, and then reinforced by mechanical needle punching, thermal bonding, or chemical bonding.

Features: The appearance is cloth like, isotropic (with little difference in performance in all directions), and has good extensibility and flat drainage ability. Mainly used for filtration, isolation, drainage, and protection.

Common applications: highway subgrade isolation, landfill filter layer, drainage blind ditch wrapping.

2. Woven geotextile:

Manufacturing process: The yarn (single, double or flat) is interwoven in two parallel directions (warp and weft), similar to traditional textiles.

Features: Stable structure, high tensile strength, but uniform and relatively small pores, low elongation. Mainly used for reinforcement, strengthening, and protection, its filtering performance needs to be carefully evaluated.

Common applications: reinforced soil retaining walls, soft soil foundation reinforcement, and geotextile bag slope protection.

Relatively few applications, it is composed of yarn coils that are interwoven with each other and have a certain degree of elasticity.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Isolation function:

Scenario: Building roads, railways, or parking lots on weak foundations.

Function: Laying between the roadbed and the foundation soil to prevent crushed stones and other fillers from sinking into the soft foundation, while preventing soft soil from upwelling, maintaining the thickness and bearing capacity of the fillers, and reducing uneven settlement.

2. Filtering function:

Scene: Drainage system behind dams and retaining walls, filter layer for river and coastal slope protection.

Function: Allow water flow to pass smoothly while preventing excessive loss of soil particles and preventing piping damage, known as "permeable but impermeable".

3. Drainage function:

Scenario: Internal drainage of earth dams, drainage around tunnels, and blind underground drainage ditches.

Function: By utilizing the pores of geotextile itself or combining with drainage core materials, excess water in the soil is collected and discharged along its plane, reducing pore water pressure.

4. Reinforcement effect:

Scenario: Reinforced earth retaining wall, steep slope reinforcement, roadbed on soft soil foundation.

Function: Utilizing its high tensile strength, it generates friction with the soil, disperses soil stress, limits lateral displacement, and thus improves the overall strength and stability of the soil.

5. Protective function:

Scenario: As a protective layer of geomembrane (anti-seepage material) to prevent it from being punctured; Cushion protection for underwater pipelines and culverts.

Function: Buffer the impact of external loads and reduce damage to sensitive materials in the lower layer.

6. Other comprehensive applications:

Landfill site: used for lining systems (isolation, protection) and leachate collection systems (filtration, drainage).

Ecological slope protection: combined with vegetation to prevent soil erosion and promote greening.

In summary, geotextile, as a multifunctional geosynthetic material, has become an indispensable and important component of modern civil engineering construction due to its excellent performance and economic benefits, providing strong guarantees for the safety, durability, and economy of the project.