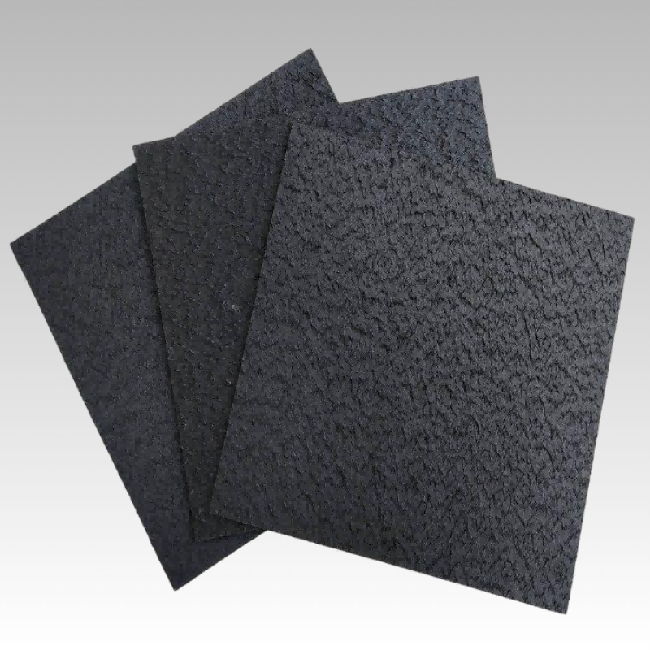

HDPE Pond Liner

1.Good anti-seepage effect:Effectively prevent liquid leakage, protect soil and water sources.

2.Excellent durability:Corrosion resistance, aging resistance, long service life, and reduced maintenance.

3.Easy construction:Lightweight and easy to transport, fast laying and splicing, shortening the construction period.

4.High cost-effectiveness:Reasonable initial investment and low long-term maintenance costs.

5.Widely applicable:Adapt to the needs of multiple fields such as water conservancy, environmental protection, and municipal administration.

Product Introduction

1.Basic attributes

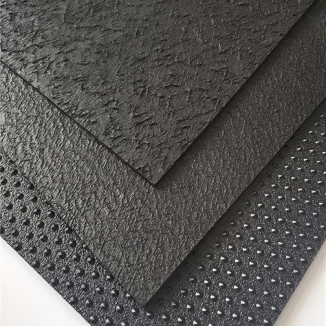

In addition to high-density polyethylene (HDPE) and polyvinyl chloride (PVC), the raw materials for making HDPE Pond Liner also include synthetic materials such as linear low-density polyethylene (LLDPE) and ethylene vinyl acetate copolymer (EVA). The performance of geomembranes made from different raw materials has its own emphasis, for example, HDPE material has more outstanding strength and weather resistance, while EVA material has better flexibility. In addition to blow molding and rolling, the production process also includes casting and other methods, which determine the thickness uniformity and physical properties of the geomembrane. In terms of physical form, in addition to common thin film like rolls, some special purpose geomembranes are made into sheet or textured styles, with a thickness range that can be further refined, ranging from ultra-thin 0.1mm to thickened 5mm. The width is usually 2-8 meters, which can meet the laying needs of different projects.

2.Core functions

Anti leakage function: Through its own impermeable properties, it can prevent water leakage and improve water resource utilization efficiency in water conservancy projects such as dams and reservoirs; In environmental protection engineering, materials such as sewage treatment tanks and landfills can prevent harmful substances from infiltrating and polluting the surrounding environment, making them the core materials of the engineering anti-seepage system.

Isolation function: In road construction, the roadbed is isolated from the foundation soil to prevent moisture and fine particles from entering the roadbed, ensuring the strength and stability of the roadbed; In yard engineering, different types of materials can be separated to prevent quality issues caused by mixing and maintain material purity.

Protective function: In geotechnical engineering, it can protect reinforced materials such as geogrids from the wear of sharp particles in the soil, extending their service life; In channel engineering, it can reduce the erosion of water flow on channel slopes and protect the integrity of slope structures.

3.Main features

The chemical corrosion resistance of geomembranes is not only reflected in their resistance to acids, bases, and organic solvents, but also in their ability to withstand certain concentrations of salt solutions, making them suitable for engineering projects in coastal and other saline alkali environments. In terms of construction, in addition to convenient transportation and laying, there are various splicing methods, such as hot melt welding, adhesive bonding, mechanical stitching, etc., which can be selected according to different materials and engineering requirements to ensure the sealing of the joints. In terms of durability, high-quality geomembranes can have a service life of 30-50 years under normal usage conditions, and have excellent resistance to UV aging. They can be used in outdoor environments for a long time without easy degradation. In addition, it also has the characteristic of light weight, with a weight of usually between 0.1-2kg per square meter, which reduces the difficulty of handling during construction and the load requirements on the base layer. Its scope of application covers anti-seepage, isolation, and protection projects in many fields such as water conservancy, environmental protection, municipal engineering, transportation, and mining.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

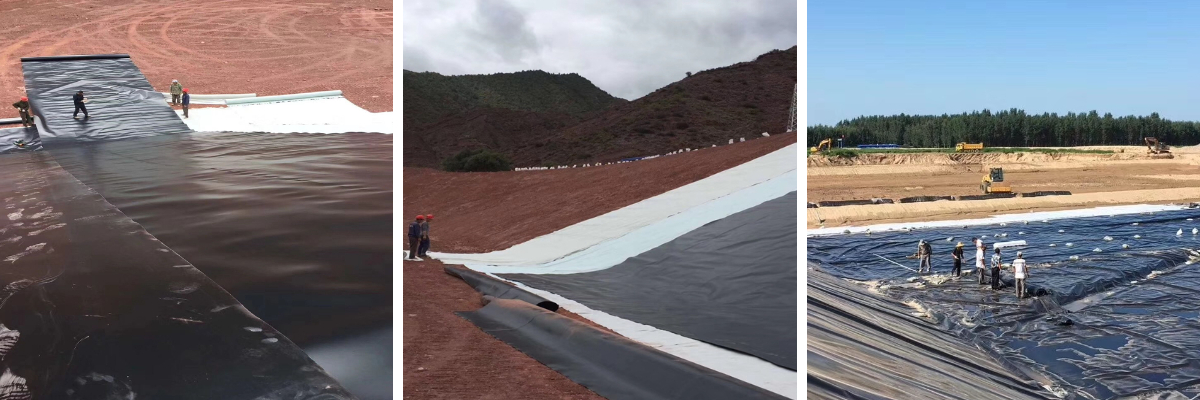

Product Application

1.Water conservancy engineering

Used for reservoirs, dams, channels, etc., to play an anti-seepage role, reduce water leakage, improve water resource utilization, and protect dam and channel slope structures.

2.Environmental Protection Engineering

As a geomembrane liner landfill, prevent leachate from contaminating soil and groundwater in landfills; Isolate sewage from the surrounding environment in the sewage treatment tank to ensure ecological safety.

3.Municipal Engineering

Applied to artificial lakes, landscape water pools, etc., to achieve anti-seepage function and maintain water landscape; In the construction of underground pipe galleries, soil moisture should be isolated to protect the structure of the pipe gallery.

4.Transportation Engineering

Used in highway and railway subgrades to isolate different soil layers and prevent roadbed deformation; In tunnel engineering, it serves as a waterproof layer to resist groundwater infiltration.

5.Mining Engineering

Used for anti-seepage of tailings ponds, preventing tailings slurry leakage from polluting the surrounding environment, while stabilizing the tailings pile and ensuring the safety of mining production.

Geomembranes are widely used in various fields such as water conservancy, environmental protection, municipal engineering, transportation, and mining due to their excellent anti-seepage and isolation properties. It not only ensures the structural stability and safety of various engineering projects, but also plays a key role in water resource protection, ecological environment maintenance, and other aspects. It is an indispensable and important material in modern engineering construction.