Nonwoven Drainage Fabric

1. Efficient drainage: The three-dimensional fluffy structure quickly guides water, accelerates the discharge of surface and soil water, and prevents waterlogging and moisture

2. Fine filtration: intercepting fine soil particles to prevent blockage, protecting the drainage system from blockage, and maintaining long-term drainage efficiency

3. Flexible and snug fit: The texture is soft and easy to cut, tightly fitting complex terrain without any drainage blind spots

4. Corrosion resistant and durable: resistant to acid and alkali, resistant to microbial erosion, not easily degraded when buried or exposed for use, long service life

Products Introduction:

Nonwoven Drainage Fabric is a type of three-dimensional fluffy structure geosynthetic material made from short fibers of polypropylene (PP) or polyester (PET) through needle punching or thermal bonding processes. Its core function focuses on the synergistic effect of "efficient drainage+fine filtration". The porous network formed by random interweaving of fibers can quickly guide surface water accumulation and soil seepage, and accurately intercept fine soil particles to prevent drainage channel blockage. It is mainly used to solve problems such as "water retention, soil softening, and drainage system failure" in engineering.

Product Features:

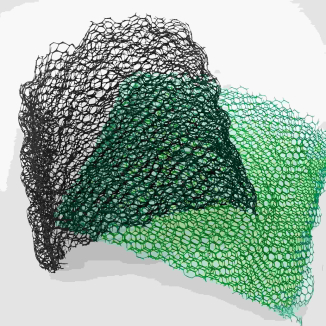

1. Three dimensional fluffy structure, high drainage efficiency

The needle punching process is used to form a three-dimensional interlaced porous structure of fibers, with a porosity of up to 70% -85% and good pore connectivity. The permeability coefficient can reach 1 × 10 ⁻² -1 × 10 ⁻³ cm/s, which is much higher than that of ordinary soil (1 × 10 ⁻⁴ -1 × 10 ⁻⁵ cm/s). This structure can quickly collect and divert surface rainwater and soil capillary water, shorten the retention time of accumulated water - for example, in slope drainage, it can increase the seepage discharge speed by 3-5 times, effectively reduce soil pore water pressure, and avoid landslides caused by soil softening.

2. Fine filtration and anti clogging, long-lasting stability

The pore size formed by random interweaving of fibers is uniformly controllable (0.05-0.2mm), with a retention rate of ≥ 95% for soil fine particles (particle size ≥ 0.075mm), which can prevent fine soil from entering drainage channels (such as gravel layers and drainage pipes) with water flow, avoiding channel blockage and drainage failure. At the same time, the integrated design of the filter layer and drainage layer eliminates the need for additional filter layers, simplifies the engineering structure, and ensures the long-term smoothness of the drainage system, with a service life of up to 5-15 years (depending on the usage environment).

3. Flexible and snug fit, suitable for complex terrains

Soft texture and good ductility (fracture elongation of 25% -40%), can naturally fit irregular terrain such as undulating surfaces, curved slopes, narrow ditches, etc., without blind spots for laying; Lightweight (80-300g/m ²), with a single roll length of up to 50-100m, easy to cut, and can be laid manually. It is particularly suitable for scenarios such as garden flower beds and building foundation pits with limited construction space, solving the pain points of rigid drainage materials that are difficult to bend and prone to breakage.

4. Corrosion and weather resistance, strong environmental adaptability

The raw materials have undergone anti UV, anti acid and alkali, and anti microbial treatment, and can be stably used in the temperature range of -30 ℃ to 70 ℃. They are resistant to erosion from saline alkali soil, groundwater immersion, and outdoor sun and rain exposure; In acidic soil (pH 4-6) or alkaline soil (pH 8-10), the performance degradation rate is less than 5% per year. When buried underground, it can also resist rodent bites and plant root punctures, making it suitable for a variety of complex environments.

5. Controllable cost and convenient construction

The unit price of materials is only one-third to one-half of that of plastic drainage boards, and the laying efficiency is high (manual laying speed can reach 800-1000 square meters per day), without the need for large machinery, greatly reducing project costs; It can be directly combined with materials such as gravel, drainage pipes, geomembranes, etc., with strong compatibility - for example, it can be used in conjunction with gravel layers to form "drainage blind ditches", and in conjunction with geomembranes for roof greening drainage, adapting to the engineering needs of multiple process combinations.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Landscape Architecture and Municipal Greening

Roof and Vertical Greening: Installed between the green substrate and impermeable membrane, it quickly diverts excess water from the substrate, prevents plant root rot, and intercepts fine particles from the substrate to avoid blocking drainage holes. It is suitable for roof gardens and vertical wall greening projects.

Flower beds and landscape slopes: Lay at the bottom of the flower beds and in the soil layer of the landscape slope to divert rainwater and prevent water accumulation from washing away the soil, prevent soil erosion on the slope, and create an ecologically stable landscape environment with vegetation planting, suitable for urban parks and residential green belt scenes.

2. Road and Traffic Engineering

Road subgrade drainage: laid under the slope or shoulder of the subgrade, coordinated with drainage blind ditches, to divert seepage from the subgrade, prevent rainwater from infiltrating the subgrade and causing soil softening and pavement cracking, and adapt to the subgrade protection of highways and rural roads.

Parking lots and squares: Lay permeable bricks between the base layer and soil in parking lots and municipal squares to accelerate rainwater infiltration and drainage, avoid surface water, and protect the gravel layer of the base layer from being blocked by fine soil, suitable for permeable paving projects.

3. Architecture and Foundation Engineering

Building foundation pit drainage: Lay around the perimeter of the foundation pit, connect with drainage pipes to form a drainage system, quickly discharge seepage from the foundation pit, lower the groundwater level, ensure the safety of foundation pit excavation construction, and adapt to the foundation pit support of small and medium-sized building projects.

Basement moisture-proof: It is laid between the outer side of the basement wall and the soil to divert water seepage around the wall and prevent moisture from seeping into the interior, causing the wall to become damp and moldy. It is suitable for basement moisture-proof engineering in residential and commercial buildings.

4. Agriculture and Water Conservancy Engineering

Irrigation channels for farmland: laid on the slope and bottom soil layer of the channel to prevent channel collapse and siltation caused by water flow erosion, while accelerating the discharge of excess water in the channel, avoiding soil salinization, and adapting to agricultural water conservancy renovation projects.

Fish pond and reservoir: laid at the bottom of the fish pond dam and reservoir to divert seepage from the dam, prevent softening and landslides, filter impurities in the water, maintain clean water quality, and adapt to the construction of aquaculture and agricultural reservoirs.

Nonwoven Drainage Fabric, with its core advantages of "integrated filtration and drainage, flexible adaptation, weather resistance and durability, and economic convenience," accurately solves the core pain points of "difficult drainage of accumulated water, easy blockage of drainage systems, and high construction costs" in various fields of engineering. It is a drainage protection material that combines functionality and cost-effectiveness.

Compared to traditional drainage solutions, it not only achieves dual guarantees of drainage efficiency and long-term effectiveness through a "three-dimensional fluffy structure+fine filtration", but also significantly reduces the threshold and cost of engineering due to its lightweight and easy to construct characteristics. From micro drainage for landscaping and greening to system protection for road subgrade, from moisture-proof building foundations to channel maintenance for agricultural water conservancy, non-woven drainage fabric can provide efficient and reliable drainage solutions for engineering in flexible application forms, promoting the development of modern engineering towards "green drainage and long-term protection", and becoming an indispensable basic material in drainage engineering in various industries.