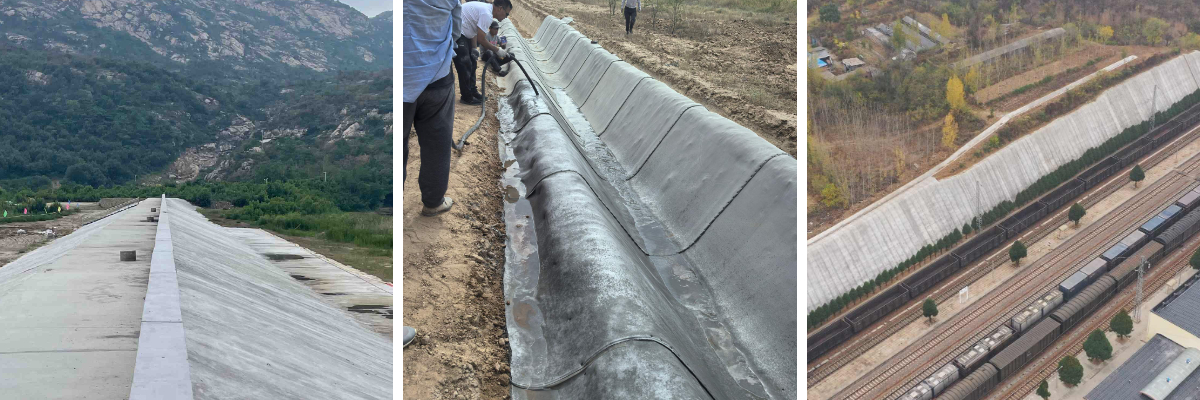

Temporary Access Roads and Worksite Stabilization Using Cement Blankets

Introduction: The Challenge of Unstable Worksites

Construction, utility, and landscaping initiatives frequently face a critical, time-consuming challenge: developing stable, all-weather get right of entry to and work systems on soft, wet, or uneven ground. Traditional strategies like importing and spreading gravel are costly, messy, and temporary, regularly requiring repeated protection and considerable website restoration. Similarly, the use of simple plastic ditch liner substances as a floor cowl offers minimal structural assist and fails below heavy loads. Today, a modern answer is reworking website online logistics: Cement Blanket Technology. This revolutionary product affords a rapid, durable, and low-cost technique for growing instant-access roads, stabilizing crane pads, and defending touchy ground, all whilst offering most effective overall performance in contrast to brief liner for drainage ditch substances used for simple soil separation.

What Are Cement Blankets for Stabilization?

A cement blanket is a flexible, fiber-reinforced composite mat pre-filled with a dry, cementitious powder. Delivered in rolls, it is deployed without delay onto organized ground. Once hydrated with water, it chemically healing procedures in area to structure a rigid, high-strength concrete slab—typically inside 24 hours. Unlike a easy irrigation ditch liner that solely affords a barrier, a cement blanket creates a load-bearing, structural surface. It acts as an "instant pavement," distributing heavy factor hundreds over a wider region to stop rutting, mud formation, and tools bogging. This makes it an critical device for worksite stabilization in difficult conditions, from soggy spring-thaw websites to sandy or dusty terrains.

The Limitations of Traditional Temporary Ground Protection

To admire the fee of cement blankets, it is vital to apprehend the shortcomings of traditional approaches:

Gravel Haul Roads: Require steady import of pricey aggregate, heavy equipment for spreading and compaction, and later elimination or high priced regrading. They create dust, permit mud to push up through, and degrade rapidly underneath heavy traffic.

Wood Chip or Mulch Paths: Offer restricted load-bearing capacity, decompose, and shift underfoot. They are unsuitable for heavy gear and supply no stabilization for crane or piling operations.

Plastic Sheeting and Geotextiles: A fundamental plastic ditch liner or woven material offers soil separation however zero structural integrity. It tears underfoot, presents no traction, and honestly traps mud and water underneath, frequently making prerequisites worse. While beneficial as a liner for drainage ditch, it fails as a stabilization mat for car traffic.

Steel Planking (Mats): Extremely heavy, high priced to transport and handle, and require cranes for placement. They can warp, create tripping hazards, and do no longer conform properly to uneven ground.

Cement blankets without delay tackle these troubles by using combining handy deployment with the everlasting overall performance of concrete, casting off the cycle of import, degradation, and removal.

Key Advantages for Access Roads and Work Platforms

The advantages of the use of cement blanket technological know-how for brief stabilization are transformative for undertaking effectivity and cost-control.

1. Rapid Deployment and Immediate Use:

Unroll, cut to shape, hydrate, and use. Roads and pads can be geared up for mild foot site visitors within hours and for heavy tools inside a day, dramatically accelerating mission timelines in contrast to constructing a typical gravel base.

2. Superior Load-Bearing and Stability:

The cured blanket types a monolithic slab that efficaciously distributes the weight of trucks, cranes, and heavy machinery. This prevents rutting and continues a stable, degree floor in stipulations that would flip into a quagmire with different methods. This steadiness is indispensable when working close to touchy infrastructure like a everlasting irrigation ditch liner, as it prevents adjoining soil crumple and liner damage.

3. All-Weather, Mud-Free Performance:

Once cured, the impermeable concrete floor locks out water and mud. It creates a clean, safe, and dependable work region regardless of rain, getting rid of downtime due to climate and enhancing worksite protection and accessibility.

4. Conformability and Versatility:

The bendy blanket conforms to uneven ground, slopes, and contours besides the want for significant grading. It can be without problems reduce to create unique pathways, pad shapes, or to suit round present fixtures, in contrast to inflexible alternatives.

5. Cost-Effectiveness and Minimal Restoration:

While the per-square-foot cloth fee may additionally be greater than plastic sheeting, the whole venture financial savings are substantial. Savings come from eradicated gravel costs, decreased tools time for set up and removal, and near-zero maintenance. At undertaking end, the blanket can frequently be left in region to degrade naturally or be damaged up and recycled, requiring a ways much less website restoration than getting rid of heaps of contaminated gravel or a torn plastic ditch liner.

Primary Applications in Construction and Infrastructure

Cement blankets are versatile for severa transient stabilization scenarios:

Instant Access Roads: Creating steady routes for concrete trucks, transport vehicles, and employee visitors throughout tender lawns, farm fields, or muddy sites.

Crane, Piling, and Rig Mats: Providing a flawlessly level, high-strength platform for heavy lifting operations, making sure security and stopping floor failure.

Temporary Worksites and Laydown Areas: Stabilizing floor for cloth storage, tools parking, and transportable workplace placements, retaining belongings easy and accessible.

Event and Utility Access: Creating brief pathways for festivals, emergency response, or utility line restore that defend underlying turf or landscaping.

Erosion Control on Slopes: Stabilizing entry and exit factors for movement crossings or slope work, stopping sediment runoff. When working in areas with water administration features, the blanket can serve as a sturdy strategy that protects the integrity of an adjoining liner for drainage ditch from being compromised by means of eroded sediment or building traffic.

Installation Process: Simple and Fast

The set up methodology underscores the product's ease of use:

Site Preparation: Clear the vicinity of giant particles and sharp objects. Minimal grading is required; the aim is a especially even surface, now not best compaction.

Deployment: Unroll the blanket at once onto the ground. Overlap adjoining rolls via quite a few inches. The cloth can be reduce with a utility knife or noticed to in shape complicated shapes or go round obstacles.

Hydration: Thoroughly saturate the blanket with water the use of a hose or water truck. The cloth matrix ensures even hydration all through the material.

Curing: Allow the blanket to cure. It units quickly, permitting mild visitors frequently inside 4-8 hours. Full remedy for heavy hundreds is commonly done in 24-72 hours, relying on conditions. No distinctive curing blankets or sprays are needed.

This procedure stands in stark distinction to the multi-step, equipment-intensive method of constructing a gravel avenue or the fragile, ineffective laydown of a simple plastic ditch liner intended for containment, now not stabilization.

Conclusion: Rethinking Temporary Site Solutions

For assignment managers, superintendents, and web site engineers, floor instability is extra than a nuisance—it is a most important supply of delay, value overrun, and security hazard. Cement Blanket Technology offers a paradigm shift in transient floor stabilization. It replaces the routine fees and mess of granular bases and the inadequacy of easy plastic sheets with a high-performance, single-application solution.

By selecting a cement blanket for your subsequent brief get admission to avenue or worksite stabilization need, you make investments in instant productivity, superior safety, and typical task value predictability. It ensures that your heavy gear maintains shifting and your time table stays on track, all whilst presenting optimal floor safety that surpasses the restricted utility of a wellknown irrigation ditch liner or different non-structural covers. Embrace this engineered answer to flip your most difficult web site prerequisites into stable, dependable assets.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province