Chemical-resistant Cement Blanket

1. Rapid and efficient setting: It solidifies with watering and takes 1-2 hours to form, greatly reducing construction time and suitable for emergency projects.

2. Labor saving: No need for on-site mixing, direct laying and cutting, reducing labor and equipment investment.

3. Durable and sturdy: After curing, it has high strength, impact resistance, weathering resistance, and long service life.

4. Strong adaptability: flexible and bendable, suitable for complex terrain, adaptable to various scenarios such as ditches and slopes.

Products Introduction:

Chemical-resistant Cement Blanket is an innovative building material that combines special fiber blankets with dry mixed cement powder. It is made of glass fiber or polyester fiber as the substrate, uniformly impregnated with quick setting cement and additives inside, and covered with a waterproof and breathable membrane on the outer layer. Its core feature is "water curing" - after laying, it only needs to be watered (or exposed to rainwater) to solidify into a sturdy concrete structure in a short time, combining the strength of traditional concrete with the flexibility of fabrics.

As an efficient material to replace traditional concrete pouring, cement blanket solves the pain points of tedious processes such as on-site mixing and formwork construction. It is widely used in emergency engineering, small-scale infrastructure, outdoor protection and other scenarios, providing a "rapid prototyping, labor-saving, and adaptable" solution for construction. It is an innovative choice in the field of modern lightweight construction.

Product Features:

1. Rapid setting molding, doubling efficiency: Initial setting begins 15-30 minutes after encountering water, and the initial strength (≥ 10MPa) can be reached in 1-2 hours. The strength can reach over 20MPa within 24 hours, and the 7-day strength is ≥ 30MPa, far exceeding the curing period of traditional concrete pouring (requiring 7-28 days). The construction efficiency is improved by more than 80% compared to traditional techniques, especially suitable for rush hour or emergency repair scenarios.

2. No need for complex processes, saving labor and costs: The cement components are pre mixed at the factory, without the need for on-site mixing, formwork support, or demoulding. Only cutting, laying, and fixing according to size, and watering are required. 1-2 people can complete the operation, reducing labor costs by more than 60%; The material is lightweight (20-30kg/m ²), easy to transport and handle, suitable for remote areas with inconvenient transportation.

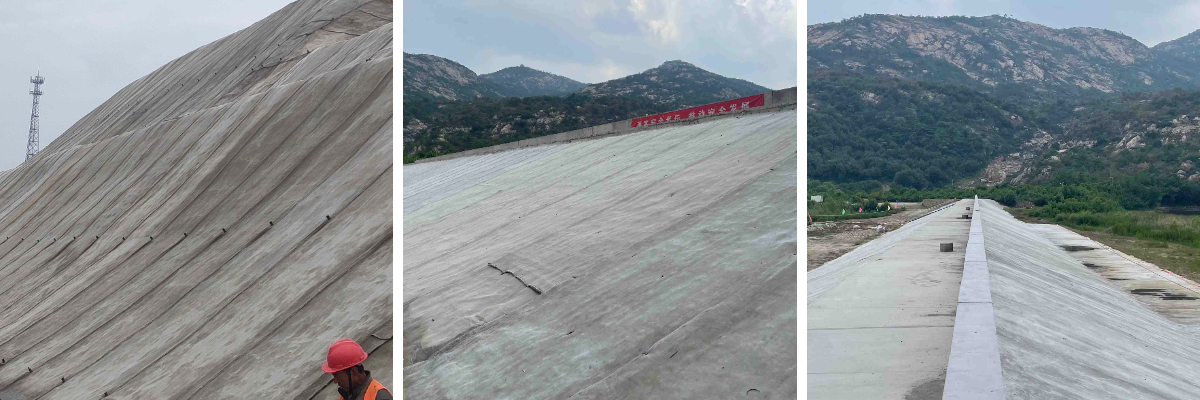

3. Flexible and adaptable to complex terrains: When uncured, the texture is soft, bendable, and foldable, and can tightly adhere to irregular surfaces (such as curved ditches, slopes, and outer walls of pipelines). After curing, it follows the shape of the base layer to avoid cracking problems caused by uneven pouring of traditional concrete; It can be cut into any size (conventional width 1-2m, length 5-10m) to meet the diverse needs of small projects.

4. Durable and weather resistant, long-lasting: After curing, it forms a dense concrete structure with excellent impact resistance and impermeability. It can withstand temperature changes from -30 ℃ to 60 ℃, resist UV aging, and has a service life of 10-20 years in outdoor environments; Surface waterproof membrane can reduce water infiltration, protect internal structure, and adapt to complex environments such as humidity and heavy rain.

Product Parameters:

Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

Freeze-thaw | Residual initial flexural | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

Construction temperature conditions | Construction above 0℃ | ||||||

Fire protecting performance | B1 | GB 8624-2012 | |||||

Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

Copper (total copper) (mg/L) | ≤100 | ||||||

Zinc (total zinc) (mg/L) | ≤100 | ||||||

Cadmium (total) (mg/L) | ≤1 | ||||||

Lead (total lead) (mg/L) | ≤5 | ||||||

Total chromium (mg/L) | ≤15 | ||||||

Nickel (total nickel) | ≤5 | ||||||

Arsenic (total) | ≤5 | ||||||

Product Applications:

1. Emergency engineering and repair: used for temporary road repair after floods and earthquakes, laying on muddy roads to quickly form hardened channels; Laying at riverbanks and channel breaches, quickly sealing gaps after watering and solidification to reduce disaster losses; Adapt to various emergency rescue scenarios to buy time for rescue efforts.

2. Small scale infrastructure and protection: used for lining rural irrigation ditches and small reservoirs, replacing traditional brick and stone masonry, quickly forming anti-seepage protective surfaces; Laying foundations for courtyard walls and fences to enhance structural stability; As the base of outdoor steps and sidewalks, it shortens the construction period and reduces labor input.

3. Slope and foundation protection: Lay and solidify a protective layer on highway and railway slopes to prevent soil erosion caused by rainwater erosion; Used for small foundation reinforcement, laid on the surface of soft soil, watered and solidified to enhance the bearing capacity of the foundation, suitable for foundation treatment of lightweight buildings such as simple warehouses and watchtowers.

4. Agriculture and landscape engineering: laying irrigation ditches and fish pond embankments in farmland to achieve rapid anti-seepage and reinforcement, and reduce agricultural water leakage; Used for the edges of paths and flower beds in garden landscapes, unique hardened surfaces are formed through cutting and shaping, balancing functionality and aesthetics.

Cement Blankets for Sale, with its core advantages of "fast setting efficiency, labor-saving, flexible adaptability, and durability", has completely changed the cumbersome mode of traditional concrete construction and provided revolutionary solutions for small-scale projects and emergency scenarios. Whether it is the infrastructure needs in remote areas or the time pressure of emergency repairs, rapid prototyping can be achieved through simple operations while ensuring structural strength and durability.

The product combines economy and practicality, significantly reducing construction barriers and costs, and adapting to diverse scenarios from emergency rescue to daily infrastructure construction. It is a representative of "efficiency, convenience, and reliability" in modern lightweight building materials, providing strong support for shortening project cycles and improving construction flexibility.