Non Woven Geotextiles in Road Construction: Enhancing Subgrade Stability and Extending Pavement Life

Road establishing needs substances that steadiness structural integrity, durability, and cost-effectiveness—especially when addressing subgrade weaknesses and pavement longevity. Non woven geotextile has emerged as a pivotal thing in modern-day avenue building, revolutionizing how engineers improve subgrades, manipulate erosion, and defend pavement. This versatile geosynthetic material works seamlessly to furnish geotextile soil stabilization, at the identical time as its porous structure acts as an first-rate geotextile filter fabric. By integrating non woven geotextile into avenue projects, contractors can mitigate time-honored troubles like subgrade settlement, drainage failures, and pavement cracking, in the stop extending the lifespan of avenue infrastructure. This records explores the characteristic of non woven geotextile in avenue construction, its core functions, and how it enhances subgrade steadiness and pavement performance.

Non Woven Geotextile: Core Properties for Road Applications

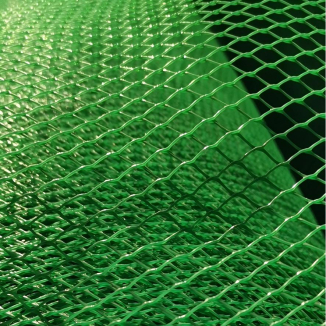

Non woven geotextile is a artificial fiber-based fabric manufactured by way of the usage of the use of bonding fibers mechanically, thermally, or chemically—creating a porous, mat-like shape satisfactory for avenue construction. Its key properties, alongside with immoderate tensile strength, permeability, and flexibility, make it well-suited for addressing avenue infrastructure challenges. Unlike woven alternatives, non woven geotextile’s random fiber affiliation enhances its attainable to distribute stress evenly, a essential attribute for geotextile soil stabilization in inclined subgrades. As a geotextile filter fabric, it traps excellent soil particles at the identical time as enabling water to go away out through, stopping drainage laptop computer clogging and subgrade saturation. Its light-weight nature simplifies transportation and installation, lowering mission timelines and labor costs. For avenue projects, non woven geotextile is generally made from polypropylene or polyester, aspects chosen for their resistance to UV radiation, chemical exposure, and herbal degradation—ensuring long-term fundamental normal overall performance in harsh outside conditions.

Geotextile Soil Stabilization: Reinforcing Road Subgrades

Subgrade instability is a foremost purpose of pavement failure, as inclined or compressible soil can no longer data the weight of website site visitors and pavement layers. Non woven geotextile offers top notch geotextile soil stabilization by means of the use of reinforcing the subgrade, enhancing its load-bearing capacity, and decreasing settlement. When set up between the subgrade and base course, non woven geotextile acts as a reinforcement layer that distributes visitors thousands evenly at some factor of the subgrade, minimizing localized stress concentrations. This prevents soil particles from transferring or being displaced via heavy loads, preserving subgrade integrity over time. As a geotextile filter fabric, it in addition controls moisture in the subgrade—allowing more water to drain away whilst retaining soil particles, which reduces pore water stress and prevents soil softening. This twin attribute of stabilization and moisture administration ensures the subgrade stays stable, even in moist or variable nearby climate conditions, laying a consistent basis for prolonged lasting pavement.

Geotextile Filter Fabric: Managing Drainage in Road Construction

Poor drainage is a essential risk to avenue longevity, as trapped water in the subgrade or base route weakens soil structure, explanations frost heave, and hurries up pavement deterioration. Non woven geotextile serves as a high-performance geotextile filter fabric, facilitating best drainage whilst stopping soil migration. Its porous shape lets in water to go with the drift freely via the fabric, away from the subgrade and pavement layers, whilst trapping awesome soil particles that ought to clog drainage systems. This ensures the subgrade stays dry and stable, lowering the hazard of frost harm in bloodless climates and soil erosion in moist regions. When paired with drainage aggregates, non woven geotextile enhances the effectivity of avenue drainage systems, directing water to sequence factors and stopping it from gathering below the pavement. Unlike ordinary drainage methods, non woven geotextile is user-friendly to set up and adapts to uneven subgrade surfaces, making fine everyday filtration and drainage in the course of the whole avenue width.

Extending Pavement Life: Non Woven Geotextile’s Protective Roles

Non woven geotextile extends pavement existence via defending it from injury delivered on through subgrade movement, erosion, and cloth mixing. One of its key shielding factors is separation—preventing the base route mixture from mixing with the subgrade soil. Without this separation, excellent subgrade soil can infiltrate the combination layer, decreasing its load-bearing performance and inflicting pavement cracking. Non woven geotextile creates a barrier that continues the integrity of each layers, making sure the base route retains its electrical power and drainage capabilities. Additionally, as a geotextile filter fabric, it prevents erosion of the subgrade surface, which can lead to uneven pavement help and untimely failure. By stabilizing the subgrade, managing drainage, and stopping fabric mixing, non woven geotextile reduces pavement stress and wear, extending its provider existence and minimizing the wish for excessive priced repairs or resurfacing.

Key Applications of Non Woven Geotextile in Road Construction

1. Subgrade Preparation and Reinforcement

In avenue construction, non woven geotextile is notably set up all by subgrade instructing to furnish geotextile soil stabilization. It is laid at as quickly as on the compacted subgrade in the previous than inserting the base course, reinforcing inclined soil and stopping settlement. This utility is specially treasured for roads developed on moderate or expansive soils, the vicinity subgrade steadiness is a primary concern. As a geotextile filter fabric, it in addition manages moisture in the subgrade, making positive the soil stays constant in the route of and after construction.

2. Pavement Edge Protection

Road edges are prone to erosion and lateral movement, which can purpose pavement cracking and thing failure. Non woven geotextile is used to toughen pavement edges, presenting geotextile soil stabilization and stopping soil erosion. It is set up alongside the segment of the subgrade and wrapped up into the pavement structure, growing a protective barrier that resists lateral soil motion and water infiltration. This utility extends the existence of pavement edges, reducing the decide on for side repairs and holding avenue width and integrity.

3. Drainage Layer Integration

Non woven geotextile is a critical problem of avenue drainage systems, performing as a geotextile filter cloth in French drains, trench drains, and permeable base courses. It traces drainage trenches and surrounds combination layers, stopping soil clogging even as enabling water to flow freely. This ensures drainage structures proceed to be functional, defending the subgrade and pavement from water damage. Non woven geotextile’s flexibility permits it to conform to the shape of drainage structures, making positive full insurance plan format and exquisite filtration.

Best Practices for Installing Non Woven Geotextile in Roads

Proper set up is vital to maximize the fundamental common overall performance of non woven geotextile in avenue construction. Start thru the use of making organized the subgrade—clearing debris, grading uneven surfaces, and compacting the soil to create a constant base. Ensure the subgrade is free of sharp objects that may additionally moreover pick out to puncture the geotextile. Unroll the non woven geotextile evenly all via the subgrade, overlapping edges via functionality of at least 15-20 centimeters to stop soil migration by way of gaps. Secure the geotextile with anchor pins to give up motion all through base course placement. When inserting the base path aggregate, use light-weight gear in the commencing to preserve away from negative the geotextile, then compact the aggregate to make high quality splendid contact with the fabric. For geotextile filter cloth applications, make superb the cloth is set up with the suitable orientation to maximize filtration and drainage. Working with educated contractors acquainted with non woven geotextile set up ensures the cloth performs optimally for geotextile soil stabilization and pavement protection.

Conclusion: Non Woven Geotextile as a Road Construction Essential

Non woven geotextile has flip out to be an necessary cloth in current day avenue construction, imparting a cost-effective, prolonged lasting reply for bettering subgrade balance and extending pavement life. Its functionality to furnish geotextile soil stabilization, act as a dependable geotextile filter fabric, and protect pavement layers from damage makes it a gold elegant choice to ordinary methods. By integrating non woven geotextile into avenue projects, engineers and contractors can mitigate typical infrastructure challenges, restriction renovation costs, and bring together roads that stand up to heavy internet site on-line web site site visitors and harsh environmental conditions. As avenue setting up continues to prioritize sustainability and longevity, non woven geotextile will proceed to be a cornerstone material, making superb the sturdiness and frequent ordinary overall performance of avenue infrastructure for many years to come.

Contact Us

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province