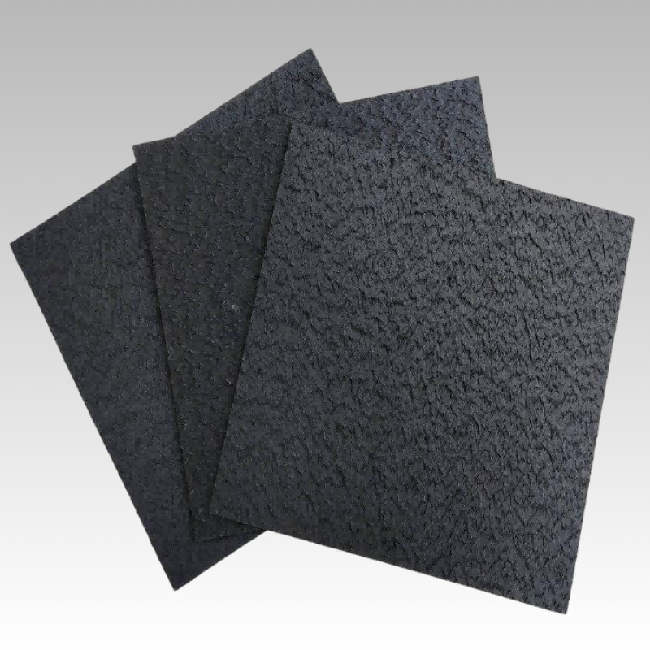

80 mil HDPE Liner

1.Excellent anti-seepage performance: The molecular structure is dense and can effectively block the penetration of liquid and gas.

2.Outstanding physical strength: Tear resistant, puncture resistant, suitable for complex construction environments.

3.Strong environmental adaptability: Chemical corrosion resistance, high and low temperature resistance, excellent aging resistance.

4.Good construction stability: Convenient and easy to weld, firm joints, and reliable long-term use.

Product Introduction

1、 Basic attributes

80 mil HDPE Liner is made from HDPE as the core material, with "30 mil" being its significant physical parameter. 1 mil is equal to 0.0254 millimeters, and the thickness of the geomembrane is approximately 0.762 millimeters after conversion. Its material has the characteristic of dense molecular structure, which lays the foundation for its various properties, and belongs to a high-performance anti-seepage engineering material.

2、 Core functions

The core function focuses on anti-seepage and barrier, and with its dense molecular structure, it can effectively prevent the penetration of liquids and gases. Whether it is preventing leachate leakage from polluting soil and groundwater in landfills, avoiding water loss in artificial lakes and water conservancy projects, or blocking the diffusion of chemical substances in chemical anti-seepage scenarios, it can reliably play a role and provide key anti-seepage guarantees for various projects.

3、 Main features

Excellent physical properties: It has outstanding strength and toughness, strong tear and puncture resistance, and can cope with stretching, rolling, and impact from foreign objects such as stones and roots in the soil during construction, ensuring material integrity.

Strong environmental adaptability: Good tolerance to chemical substances such as acids, bases, and organic solvents, and can work stably in complex chemical environments; At the same time, it has excellent resistance to high and low temperatures, can adapt to extreme climates ranging from -60 ℃ to 60 ℃, has strong resistance to UV aging, and extends its service life.

Stable construction and use: The material has good flexibility, is easy to cut and weld, has high joint strength and reliable sealing, and has high construction efficiency; After laying, it is not easily deformed and can adapt to slight settlement or displacement of the base layer. It has good long-term stability and reduces maintenance costs.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

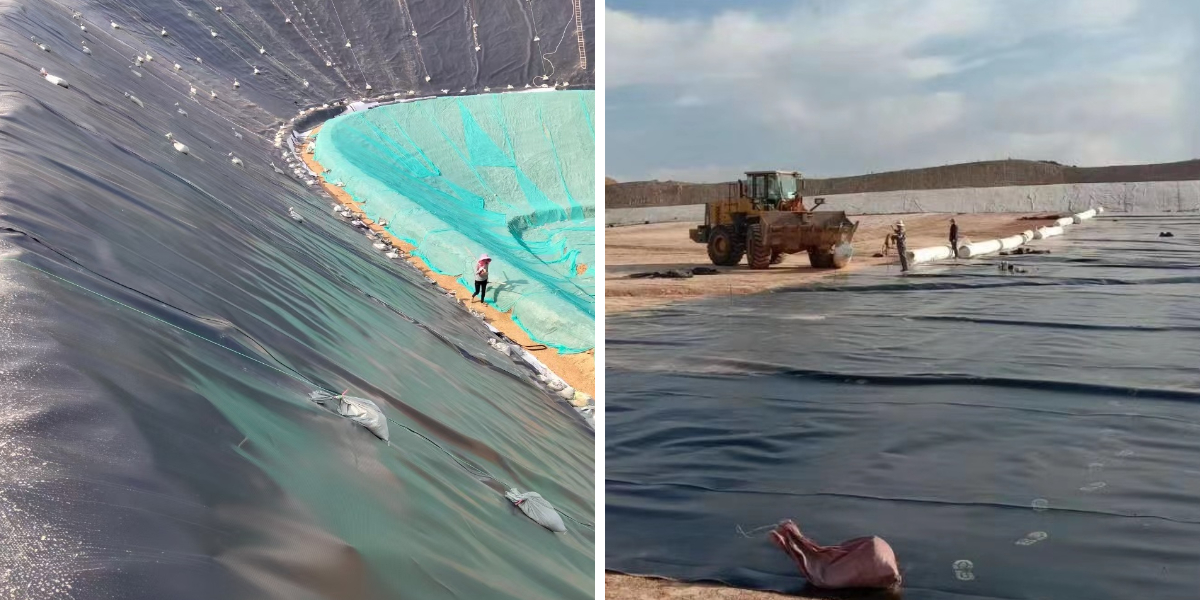

Product Application

1、 Water conservancy and waterway engineering

In hydraulic engineering, it is commonly used for anti-seepage treatment of artificial lakes, reservoirs, and reservoirs. By laying geomembranes, water leakage can be effectively reduced, ensuring the storage capacity of water resources; In river management projects, it can be laid at the bottom and slopes of the river to prevent erosion and erosion of the embankment by the river water, while also blocking the infiltration of pollutants into the soil; In addition, in the anti-seepage engineering of water transportation facilities such as canals and locks, it can also play a stable anti-seepage role, ensuring the safety of the engineering structure.

2、 Environmental Protection and Waste Management Engineering

In the construction of landfill sites, it is one of the core anti-seepage materials, which can be laid at the bottom and periphery of the landfill area to form a tight anti-seepage barrier, prevent the leakage of leachate from polluting groundwater and soil, and protect the ecological environment; In special waste disposal scenarios such as hazardous waste disposal sites and medical waste disposal sites, the chemical corrosion resistance can effectively block the diffusion of harmful chemicals and reduce environmental pollution risks; At the same time, sedimentation tanks, regulating tanks and other facilities in sewage treatment plants can also be used for anti-seepage and to improve sewage treatment efficiency.

3、 Municipal and Industrial Engineering

In the municipal field, it is suitable for laying anti-seepage layers in underground comprehensive pipe galleries to prevent groundwater from seeping into the interior of the pipe gallery and ensure the normal operation of pipeline equipment; In municipal landscape projects such as rooftop gardens and landscape water bodies, it can be used as an anti-seepage substrate to prevent water infiltration from affecting building structures; In terms of industry, in the anti-seepage engineering of factory areas in chemical, metallurgical, pharmaceutical and other industries, it can resist the erosion of various acid-base solutions and organic solvents, and is used for anti-seepage in workshop floors, tank areas, wastewater treatment tanks and other areas to ensure industrial production safety.

4、 Agricultural and Mining Engineering

In the field of agriculture, it can be applied to the anti-seepage of agricultural water conservancy facilities such as irrigation channels and reservoirs, reducing water resource waste and improving irrigation efficiency; In mining engineering, it is commonly used for anti-seepage treatment of tailings ponds to prevent harmful substances in the tailings slurry from leaking and polluting the surrounding soil and water sources, while reducing the amount of seepage in tailings ponds and ensuring their stability.

From the above, it can be seen that 30 mil thick high-density polyethylene (HDPE) geomembrane plays an important role in many key engineering fields such as water conservancy and water transportation, environmental waste treatment, municipal industry, and agricultural mining due to its reliable anti-seepage performance and strong environmental adaptability. It provides strong support for anti-seepage safety, ecological protection, and structural stability of various projects and is an indispensable high-performance anti-seepage material in engineering construction.