Non Woven Polypropylene Geotextile Fabric

1.Excellent drainage: Microporous soil retaining particles, fast drainage, and prevent waterlogging and erosion.

2.Weather-resistant: Acid, alkali, and UV-resistant, stable even in wet, outdoor environments.

3.Easy to install: Lightweight and flexible, it conforms to the terrain without the need for complex tools.

4.Cost-effective: Low cost and the ability to incorporate recycled materials make it both environmentally friendly and cost-effective.

Product Introduction

1. Basic Properties

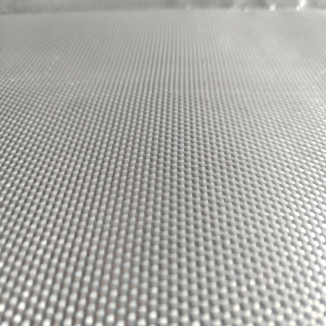

Non Woven Polypropylene Geotextile Fabric are made from polypropylene (PP) resin through nonwoven processes such as needlepunching, spunbonding, or through-through bonding. They are flexible geosynthetics. They are primarily made from homopolymer or copolymer polypropylene granules, with some products incorporating 15%-30% recycled polypropylene, balancing economical and environmental performance.

The finished product has a white or black porous mesh structure, typically ranging from 0.3-2.5mm thick, with a grammage per square meter of 80-600g/m2. Customizable geotextiles are available based on project requirements. They are lightweight (only 80-600g per square meter) and exhibit a certain degree of elasticity, adapting to slight terrain deformation. They are an economical geotextile commonly used in municipal administration, horticulture, and water conservancy projects.

2. Core Functions

Dual Filtration and Drainage: The micropores (pore size 0.02-0.15mm) created by the nonwoven process precisely capture fine soil particles (such as silt and sand), preventing soil erosion. Simultaneously, the micropores form continuous permeable channels that quickly drain rainwater, groundwater, or seepage water from the project area, preventing waterlogging of roadbeds, slopes, or embankments, and reducing structural subsidence and cracking caused by water erosion. Typical applications include roadbed drainage layers and slope filter layers.

Dual Isolation and Protection: It can serve as a "separator" between different materials. For example, in a roadbed, it can separate the soil base from the gravel cushion layer to prevent mixing of soil and gravel, which can weaken the base layer. In gardening, it can also separate soil from the gravel drainage layer to prevent blockage of drainage channels. Furthermore, its flexible structure can cushion external impacts, protecting fragile materials such as the geomembrane and pipes below from puncture damage caused by sharp rocks and construction debris.

3. Key Features

Strong Weather and Corrosion Resistance: Polypropylene is inherently chemically stable and can withstand acidic and alkaline environments with a pH of 2-12 (such as saline-alkali land and industrial wastewater areas). It also offers excellent resistance to UV aging. Even in outdoor environments, products with anti-aging treatments can maintain performance for 3-5 years with no noticeable degradation. Non-anti-aging products can also meet short-term project requirements of 1-2 years. It is resistant to decomposition by soil microorganisms and is suitable for complex applications such as humid and outdoor environments.

Excellent Construction Adaptability: Its soft and flexible texture allows for easy folding and cutting, allowing it to conform to irregular terrain such as slopes, depressions, and trenches, eliminating the need for large construction equipment. Roll packaging (1-6m wide, 50-100m long) is easy to carry, allowing a single person to complete the installation process, significantly reducing construction complexity and improving efficiency.

Economical and environmentally friendly: Polypropylene raw material is cheaper than polyester (PET), and recycled materials can be incorporated, making production and procurement costs significantly lower than other types of geotextiles. The product can be recycled and reprocessed after disposal, or slowly degrade in the natural environment (without releasing toxic or hazardous substances), meeting the requirements of green engineering projects for environmentally friendly materials and offering an excellent overall cost-effectiveness.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1. Municipal and Gardening Applications: Balancing Practicality and Ecology

Garden Weed Control and Soil Protection: Applied on the surface or beneath vegetation in gardens and green belts, this barrier physically inhibits weed growth and reduces pesticide use. It also maintains soil air and water permeability, ensuring plant root respiration and rainwater infiltration. It also prevents soil particle loss during watering or rainfall, keeping flower beds and lawns neat and tidy.

Municipal Drainage and Sponge City Construction: Applied on the base of permeable sidewalk pavement, rain gardens, or sunken green spaces, it filters impurities such as silt, fallen leaves, and rainwater runoff, preventing clogging of the permeable layer or drainage pipes. It also helps quickly drain excess water, alleviating urban flooding and meeting the "infiltration, retention, and drainage" requirements of sponge cities.

Landscape Isolation: Applied behind rockery, water feature slopes, or retaining walls, it isolates soil from landscape decorative materials (such as gravel and pebbles), preventing soil from mixing with the landscape and causing clutter. It also prevents soil particles from being washed away by water, protecting the stability of landscape structures and extending maintenance cycles.

2. Water Conservancy and Soil and Water Conservation Projects: Anti-scour and Water Filtration Structures

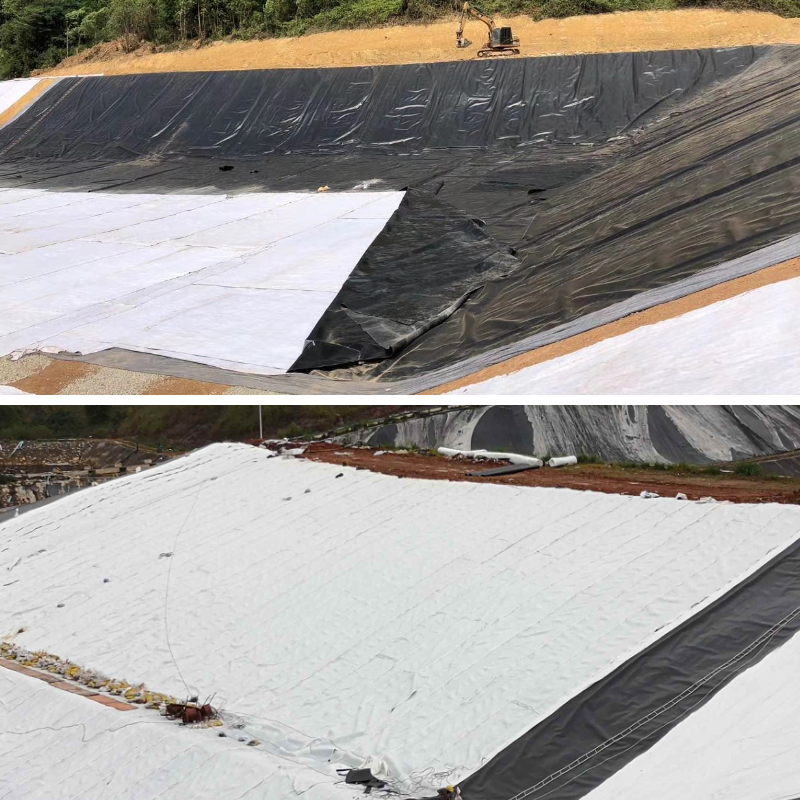

Slope and Dam Protection: Installed on the slopes of rivers, reservoirs, or small dams, it filters soil particles to prevent soil erosion and reduces direct erosion. Combined with materials such as eco-bags and gabion nets, it provides a dual "protection + ecological" approach, making it particularly suitable for small and medium-sized water conservancy projects.

Agricultural Irrigation Channel Anti-seepage Aid: Installed on the inner walls or bottom of irrigation channels, it acts as a protective layer for geomembranes, preventing sharp rocks from puncturing the membrane during channel excavation. It also filters sediment from irrigation water, preventing clogging of membrane joints, improving channel anti-seepage effectiveness, and reducing water waste.

3. Road and Infrastructure Projects: Strengthening the Base Layer and Reducing Losses

Rural Road and Temporary Access Road Base Layer: Paved between the road's soil and gravel base, it isolates the soil and gravel, preventing vehicle traffic from mixing soil and gravel, and preventing loosening and subsidence of the base layer. It also drains accumulated water from the base layer, reducing rainwater erosion and extending the service life of rural roads and temporary construction access roads.

Parking Lot and Hardened Surface Sub-base: Used beneath the base layer of hardened surfaces in open-air parking lots and factory areas, it strengthens the soil's bearing capacity and prevents ground subsidence and cracking caused by parking. It also isolates the soil from the concrete/asphalt layer, preventing evaporation and hollowing of the ground, reducing subsequent repair costs.

4. Environmental Protection and Public Welfare Projects: Pollution Control, Protection, and Safety

Small Waste Transfer Station and Leachate Treatment: Paved on the ground surface of small waste transfer stations or at the bottom of leachate collection tanks, it isolates waste from the soil and prevents leachate from seeping into the ground and contaminating groundwater. It also filters impurities in the leachate, preventing clogging of collection pipes and streamlining the leachate treatment process. Household or small farm drainage trenches: Lay the trench walls to prevent soil erosion caused by sewage scouring and avoid trench collapse. It also filters impurities such as feces and debris from the sewage, reducing pipe blockage and simplifying maintenance of small sewage systems.

Nonwoven polypropylene geotextiles, with their core functions of filtration, drainage, isolation, and protection, along with their economical, easy-to-apply, and adaptable nature, have become a lightweight engineering material for diverse sectors, including municipal administration, water conservancy, road construction, and environmental protection. They address specific pain points in diverse scenarios, such as weed control in gardens, roadbed reinforcement, and sewage leakage prevention. They also address ecological needs (such as water retention and air permeability, reducing pollution) and cost controls (such as lowering maintenance costs and adapting to small and medium-sized projects). Their high cost-effectiveness makes them a preferred material for balancing practicality and affordability, particularly in small and medium-sized projects and for public welfare applications. They provide fundamental support for the stable operation of various projects and ecological protection.