Geotextile Road Fabric

1. Efficient filtration and stable soil and water: Geotextiles have precise pore structures that can effectively intercept soil particles while allowing water to penetrate smoothly, avoiding soil erosion.

2. Excellent drainage, flood prevention and moisture resistance: Its three-dimensional permeable structure can quickly drain accumulated water inside the structure, reducing settlement or damage caused by accumulated water in the project, and is suitable for drainage systems in roadbeds and landfills.

3. Strengthen protection and extend service life: It can buffer external impacts, disperse load pressure, protect soil, pipelines and other structures from mechanical wear or environmental erosion, and improve the overall durability of the project.

4. Convenient construction and controllable cost: light weight, good flexibility, rapid cutting and laying, acid and alkali resistance, anti-aging, reducing the frequency of later maintenance, and lower comprehensive construction and maintenance costs.

Products Introduction:

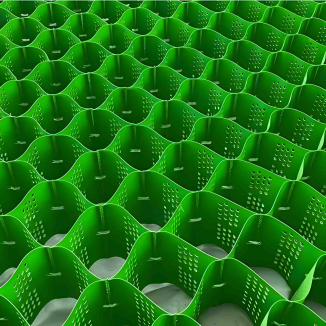

Geotextile Road Fabric is a polymer synthetic material designed specifically for road engineering, made from high-strength fibers such as polyester and polypropylene through needle punching, weaving, or thermal bonding processes. It has excellent mechanical properties and chemical stability, and can play multiple roles in road construction such as filtration, drainage, reinforcement, and protection. It is an indispensable key material in modern road engineering. This product not only has light weight and good flexibility, but also has anti-aging, acid and alkali resistance, corrosion resistance and other characteristics. It can adapt to various complex geological and climatic environments and provide long-term stable protection for road structures.

Product Features:

1. High strength and durability: Made of high-quality polymer materials, it has high tensile strength and tear strength, and can effectively resist various loads and external impacts during road construction and use. At the same time, its anti-aging performance is excellent. Under the influence of natural environmental factors such as sunlight, rain and temperature changes, it can still maintain good performance and long service life.

2. Excellent filtration and drainage performance: The unique fiber structure gives it a reasonable porosity, which can prevent soil particles from passing through, prevent soil loss from the roadbed, and allow water to penetrate and be discharged smoothly, avoiding roadbed water accumulation and reducing problems such as road settlement and deformation caused by water accumulation.

3. Good reinforcement effect: When laid in the roadbed, it can tightly bond with the soil, enhance the overall stability and bearing capacity of the roadbed through friction and anchoring, effectively disperse vehicle loads, reduce uneven settlement of the roadbed, and delay road damage.

4. Easy to construct and maintain: The product has a soft texture, light weight, and can be cut and spliced according to construction needs. The laying process is simple and convenient, which can greatly improve construction efficiency. In addition, its maintenance cost is low in the later stage, and there is no need for frequent replacement and repair.

5. Environmental friendliness: The materials used comply with environmental standards, will not cause pollution to the environment during use, and some products can be recycled, in line with the environmental protection concept of modern engineering construction.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Road base reinforcement: Laying geotextile on the base of newly built roads can effectively enhance the bearing capacity of the base, reduce deformation caused by vehicle loads, and extend the service life of the road, especially suitable for road construction on soft soil foundations.

2. Roadbed drainage system: It can serve as an important component of the roadbed drainage layer, quickly draining accumulated water from the roadbed, reducing its moisture content, preventing roadbed softening, and improving road stability.

3. Road surface protection: Laying geotextile between the road surface and the base layer can serve as a barrier to prevent the mixing of road surface materials and base layer materials, while reducing the occurrence and propagation of road surface cracks and protecting the road surface structure.

4. Road maintenance and upkeep: In the renovation or repair of old roads, laying geotextiles can repair damaged roadbeds, enhance the overall integrity of the road surface, improve the quality of the repaired road, and extend the road's repair cycle.

5. Construction of parking lots and storage yards: In the ground construction of parking lots, cargo yards, and other areas, the use of geotextiles can enhance the bearing capacity of the ground, prevent ground collapse and deformation, and ensure the normal use of the site.

Geotextile Road Fabric plays a crucial role in road engineering due to its unique structure and excellent performance. It can not only improve the stability and durability of roads, reduce road construction and maintenance costs, but also adapt to various complex engineering environments, providing strong guarantees for the safe and efficient use of roads. Geotextile is an ideal engineering material for both new road construction and old road maintenance, which can effectively improve the quality and economic benefits of road engineering. It is an important innovative achievement in the field of modern road construction.