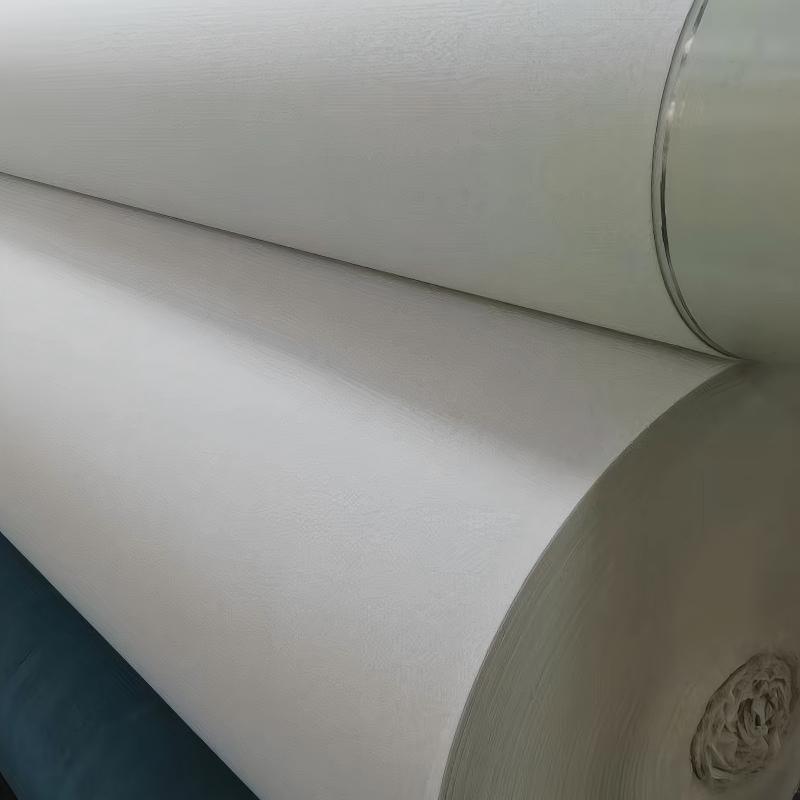

Geo Cloth

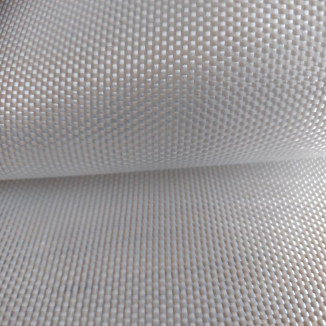

1.Excellent permeability and filtration capacity

2.Superior mechanical properties and load distribution

3.Outstanding resistance to UV radiation, chemicals and biological degradation

4.Long service life

Product Introduction:

Geo Cloth is a permeable engineering material manufactured from polymer synthetic fibers through needle-punching, weaving or thermal bonding processes, classified as a new type of geotechnical composite material.

Performance Characteristics

1.High Strength: Due to the use of plastic fibers, it can maintain sufficient strength and elongation in both dry and wet conditions.

2.Corrosion Resistance: It can withstand long-term corrosion in soil and water with varying pH levels.

3.Good Water Permeability: With gaps between fibers, it possesses excellent water seepage performance.

4.Microorganism and Insect Resistance: It is not damaged by microorganisms or insect infestation.

5.Convenient Construction: Being lightweight and flexible, it is easy to transport, lay, and construct with.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1.Reinforcement function:

This material is used in rock engineering projects such as highways, railways, airports, stone dams, breakwaters, retaining walls, and backfill. It disperses soil stress, increases the modulus of soil components, restricts soil slippage, and enhances stability.

2.Protective function:

To prevent embankments from being eroded by wind, waves, tides, and rain, and to protect shorelines, slopes, and riverbeds from soil erosion.

3. Reverse filtration:

Used in filter layers of dikes, dams, riverbanks, coastal rock structures, earth slopes, and retaining walls to prevent the passage of sand and soil particles while allowing water or air to flow freely.