Geo Membranes

1.Superior Impermeability

Made from HDPE, LDPE, PVC, or TPO materials with permeability coefficients as low as 10⁻¹³ cm/s, effectively preventing liquid and gas penetration.Resistant to acids, alkalis, salts, and organic solvents, making it suitable for corrosive environments such as landfills and chemical storage ponds.

2. High Strength & Durability

Tensile strength up to 20-40 MPa, with excellent puncture resistance, adapting to ground deformation.

3. Easy & Efficient Installation

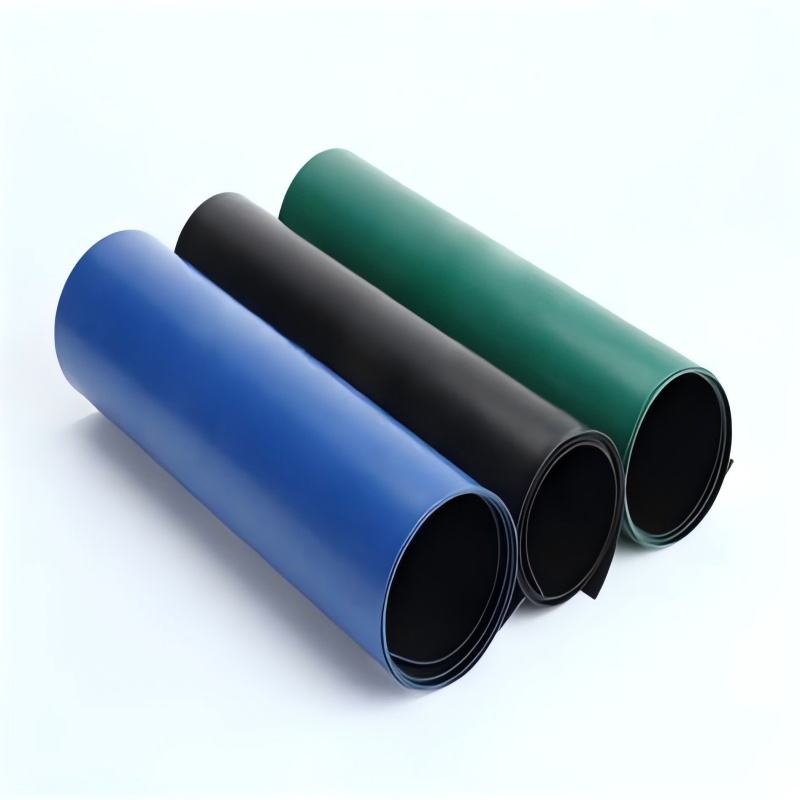

Flexible & Lightweight: Roll-form design (thickness 0.2-3.0mm), easy to transport and install.

Reliable Seaming: Heat fusion welding or adhesive bonding ensures seam strength ≥ 80% of the parent material.

Product Introduction:

Geo Membranes are blown from polymer materials such as polyethylene and can be classified into Low-Density Polyethylene (LDPE) geomembranes,High-Density Polyethylene (HDPE) geomembranes, and EVA geomembranes based on the raw materials used. These products feature high strength, excellent aging resistance, superior welding performance,and convenient construction.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

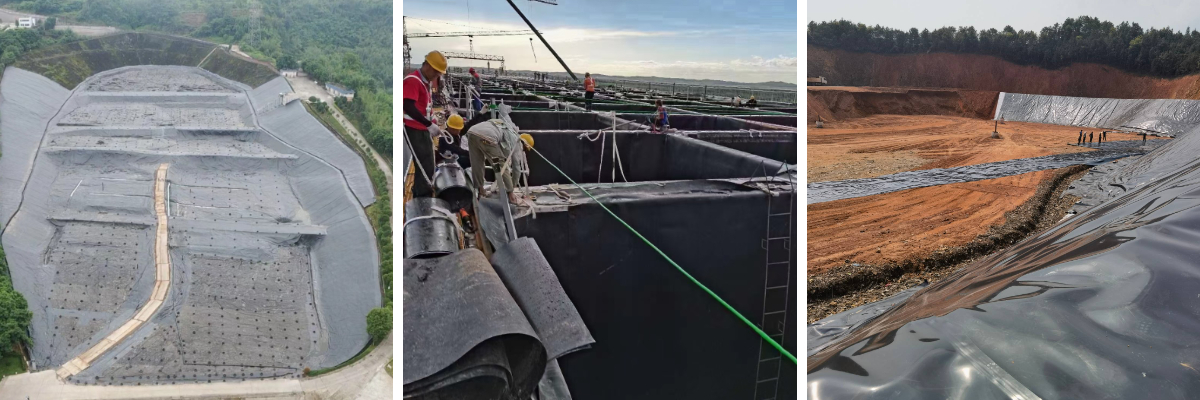

1.Environmental protection and sanitation:

Domestic waste landfills, wastewater treatment plants,equalization tanks for power plants, as well as industrial and medical solid waste disposal facilities, etc.

2.Hydraulic Engineering:

Seepage prevention, leakage sealing and reinforcement for rivers, lakes, reservoirs and dams; canal lining, vertical core walls, slope protection, etc.

3.Municipal engineering:

Subways, underground structures, green roofs, rooftop gardens (waterproofing), and sewer linings, etc.

4. landscape architecture :

Artificial lakes & decorative waterways , water storage reservoirs & containment ponds , golf course water features lining systems , slope stabilization & erosion control , waterproofing solutions for turf fields and moisture barriers for landscaped areas,etc

5.Petrochemical:

Oil containment systems and chemical reaction basins for storage tanks in chemical plants, refineries & gas stations,lining systems for sedimentation basins, secondary containment layers, etc.