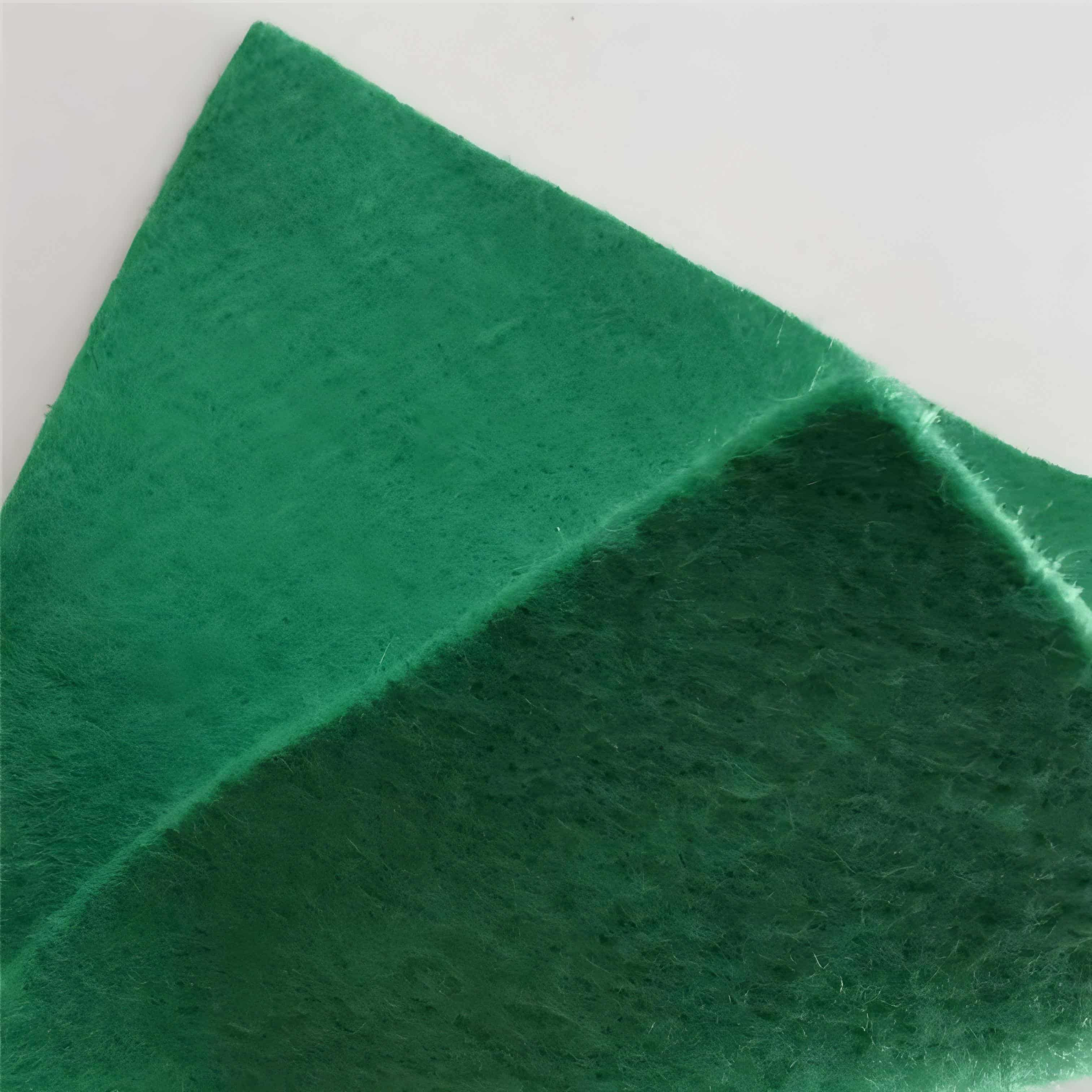

Best Non Woven Geotextile Fabric

1. Mechanical stability: High strength, maintaining strength and elongation in both dry and wet conditions, enhancing the soil's ability to resist deformation.

2. Weather resistance and corrosion resistance: Anti-aging, anti acid, alkali and salt corrosion, resistant to microorganisms and moth, suitable for long-term projects.

3. Permeable and efficient: Fiber voids allow water flow to pass through while intercepting sand, forming drainage channels.

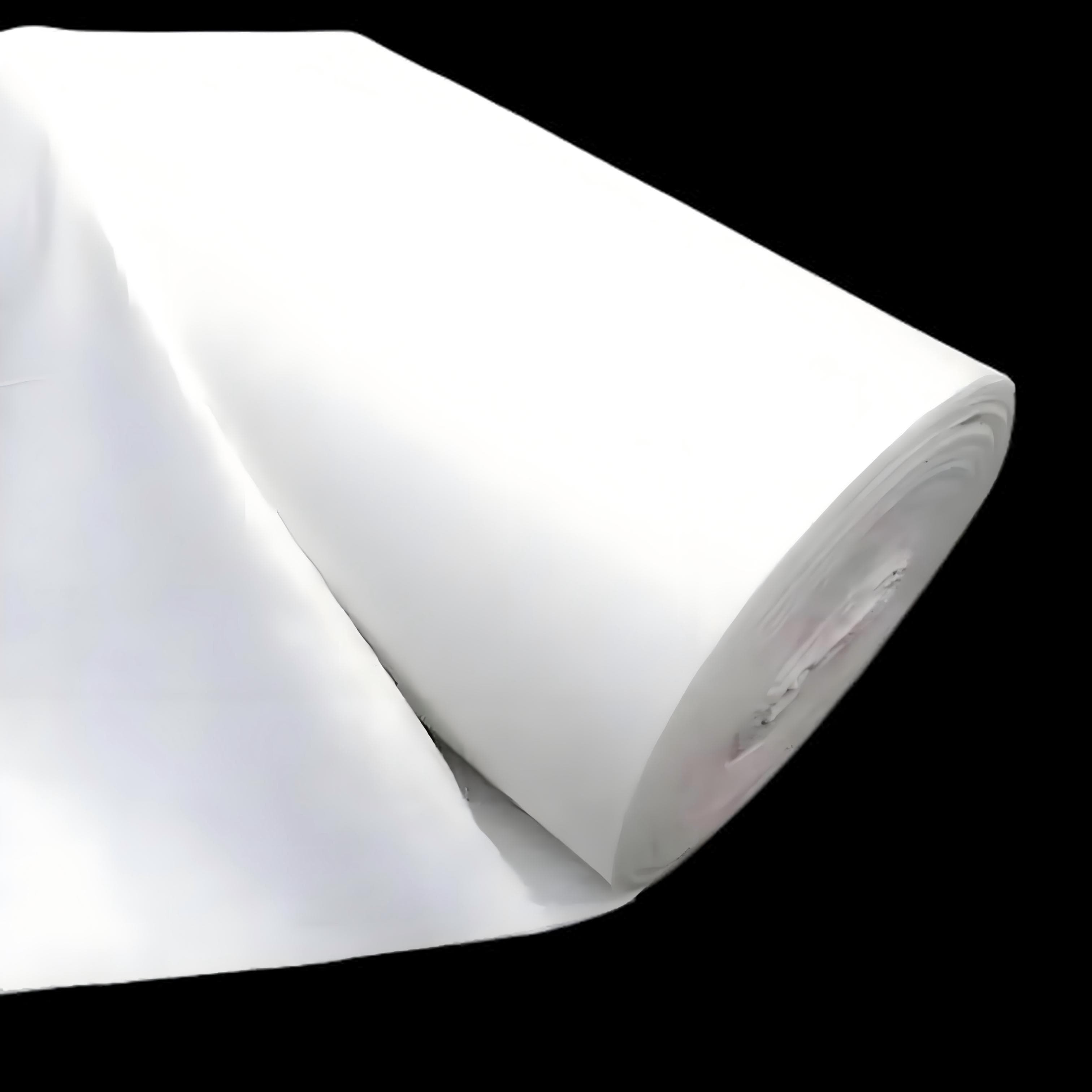

4. Convenient construction: Lightweight and soft, easy to transport and lay, complete specifications (with a width of up to 9 meters), improving efficiency.

5. Reliable isolation: Separate building materials with different physical properties to prevent mixing and loss, and ensure the structural load-bearing capacity.

Product Introduction

1.Basic attributes

Best Non Woven Geotextile Fabric are flexible sheet materials made from high molecular weight polymers such as polypropylene and polyester through non-woven processes such as needle punching, water punching, thermal bonding, or chemical bonding. They belong to an important category of geosynthetic materials. Its basic attributes can be summarized as:

Material characteristics: The porous structure is formed by random or directional arrangement of fibers, with a light texture (usually 100-1000g/㎡ per unit area) and strong flexibility. The thickness and width can be adjusted according to engineering needs (the maximum width can reach 9 meters).

Chemical stability: The raw materials themselves have the characteristics of resistance to acid and alkali, salt spray, and microbial erosion, and are not easily decomposed or aged in complex environments such as soil and water.

Physical compatibility: There are no adverse reactions when in contact with building materials such as soil, sand, and concrete, and it can adapt to the physical characteristics of different engineering media.

2.Core functions

As a key material in engineering construction, its core functions revolve around the four major engineering requirements of "enhancement, protection, diversion, and isolation":

Enhanced function: By combining with soil, it can improve the tensile strength and overall stability of structures such as foundations and slopes through its own high strength and deformation resistance, reducing the risk of settlement or collapse.

Isolation function: Separate materials with different physical properties (such as soil and sand, sand and stone), prevent material mixing and loss, maintain structural layering integrity, and ensure engineering bearing capacity.

Drainage function: By utilizing the porous structure between fibers, water can be permeated and discharged through fabrics, while retaining sand particles to prevent soil erosion and achieve "drainage without soil discharge" inside the soil.

Protective function: Covering or wrapping materials such as soil, sand and gravel, reducing direct damage to the base caused by water flow erosion, wind erosion or external loads, and extending the service life of the project.

3.Main features

Compared to traditional geotextiles or woven geotextiles, its core characteristics are reflected in practicality and engineering adaptability:

Mechanical performance balance: It can maintain stable strength and elongation under both dry and wet conditions, with excellent tear and puncture resistance, and can withstand dynamic loads during construction and operation.

High construction efficiency: lightweight and soft, easy to transport, cut and lay, no need for complex splicing processes, able to adapt to irregular terrain, greatly reducing construction period.

Long term durability: after adding anti-aging agent, it can resist the influence of environmental factors such as ultraviolet ray and temperature change, and its service life can reach decades to meet long-term engineering needs.

Outstanding cost-effectiveness: simple production process, high utilization rate of raw materials, lower cost compared to traditional materials, and the ability to reduce overall project costs by reducing post maintenance expenses.

In summary, non-woven geotextiles have become ideal materials in fields such as water conservancy, transportation, and municipal engineering due to their stable properties, diverse functions, and adaptability to engineering needs.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1.Water conservancy engineering: safeguarding water engineering safety and ecological balance

Dam construction: anti-seepage and risk control

In dam construction, non-woven geotextiles are laid between the fill soil and foundation of the dam body, which can accurately isolate soil and sand of different particle sizes, avoiding the decrease in structural strength caused by material mixing; At the same time, its excellent permeability can quickly discharge the seepage water inside the dam body, reduce the pore water pressure, and fundamentally reduce hidden dangers such as piping and landslides.

Channel engineering: Anti erosion and soil conservation

In channel engineering, fabric covering the surface of the slope can directly resist rainwater erosion and water flow impact, reducing soil erosion on the channel slope.

River regulation: constructing ecological bank protection

In river regulation, it is combined with ecological bags and vegetation to form a composite revetment structure, which not only reduces the erosion of the riverbank by water flow through physical protection, but also provides a stable base for plant growth, achieving the dual goals of soil and water conservation and ecological restoration.

2.Transportation Engineering: Building the Structural Foundation of Roads and Tracks

Roadbed reinforcement: reducing settlement and strengthening stability

Non woven geotextiles are key materials for improving foundation stability in highway and railway subgrade construction. Laying it on the base of the roadbed can disperse the load through its own high strength, enhance the deformation resistance of the foundation, and effectively reduce roadbed settlement and uneven settlement.

Structural layer isolation: anti mixing and performance protection

In the pavement structure layer, the fabric is sandwiched between the base layer and the cushion layer, which can completely isolate the sand and gravel materials from the cohesive soil, prevent different materials from losing their original properties due to infiltration and mixing, and ensure clear layering of the pavement structure.

Drainage and foundation protection: extending lifespan and reducing costs

In addition, its porous structure can quickly drain accumulated water inside the roadbed, avoiding softening of the base caused by long-term water retention, significantly extending the service life of roads and tracks, and reducing later maintenance costs.

3.Municipal and Infrastructure: Improving Facility Durability and Safety

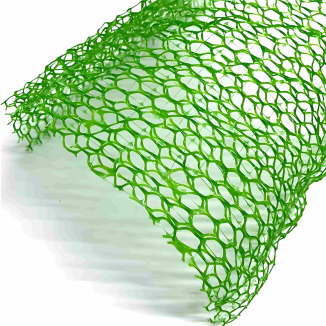

Drainage pipeline protection: isolate hard objects to prevent damage

During the construction of municipal drainage pipelines, non-woven geotextiles are wrapped around the outside of the pipeline to isolate stones, hard objects, and pipes in the backfill soil, avoiding damage to the pipeline due to backfill pressure or sharp objects. At the same time, groundwater is allowed to permeate and be discharged through the fabric, reducing the erosion of the pipeline body by accumulated water around the pipeline.

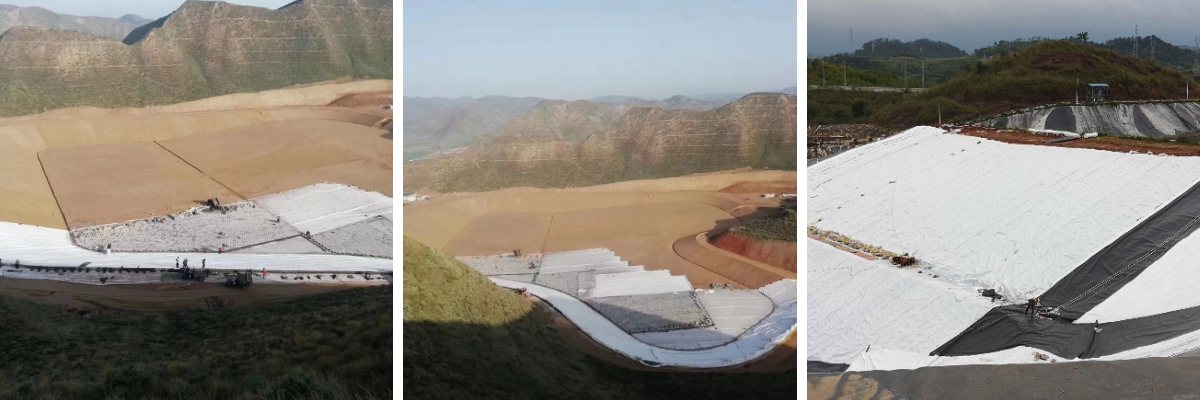

Landfill anti-seepage: protective film for filtrate

In landfill engineering, it serves as a "protective layer" for the anti-seepage layer, laid above the HDPE anti-seepage membrane, which can block sharp impurities in the garbage from piercing the anti-seepage membrane and ensure the integrity of the anti-seepage system; At the same time, the drainage function of the fabric can divert the leachate from garbage to the collection system, prevent the accumulation of leachate and damage the anti-seepage layer, and reduce the risk of environmental pollution.

4.Mining and Environmental Protection: Supporting Ecological Restoration and Pollution Prevention and Control

Mine reclamation: soil stabilization and greening promotion

In the mine reclamation project, non-woven geotextiles are laid on the mine slope to fix the surface soil through physical protection and prevent soil erosion caused by rainwater erosion; At the same time, its breathability and water retention create favorable conditions for vegetation planting, accelerating the ecological restoration of slopes.

Environmental filtration: clean water quality and drainage

In the field of environmental engineering, it is widely used as a filtering material in sewage infiltration systems and artificial wetlands. With the microporous structure between fibers, it intercepts suspended impurities in sewage and allows clear water to permeate through, maintaining good permeability during the purification of water quality, balancing filtration and drainage functions, and providing stable material support for ecological and environmental protection projects.

In summary, non-woven geotextiles play an irreplaceable role in various engineering fields due to their comprehensive performance in isolation, reinforcement, drainage, and protection. They have become the core material for improving engineering quality, ensuring safety and stability, and promoting ecological sustainability.