Geomembrana In Hdpe

1. Excellent anti-seepage performance

Extremely low permeability coefficient: up to 1×10⁻¹³ cm/s, the anti-seepage effect is one million times that of clay.

Seamless welding: The strength of hot-melt welding is ≥ that of the base material, ensuring the integrity of the overall anti-seepage system.

2. Super corrosion resistance

It can withstand an environment with a pH range of 1 to 14 and is resistant to erosion by over 200 kinds of chemical substances.

It has passed the GB/T 17642 chemical corrosion resistance test and is suitable for scenarios such as chemical waste liquid pools.

3. High mechanical strength

Tensile strength ≥25MPa, elongation at break ≥600%, adaptable to foundation deformation.

The puncture resistance strength is ≥500N, effectively resisting damage from sharp objects such as crushed stones and tree roots.

4. Economically efficient

Low comprehensive cost: Reduce the construction and maintenance costs of traditional anti-seepage materials (such as concrete).

Construction period shortened by 50% : The laying of rolls and welding process simplify the construction procedure.

5. Eco-friendly

Non-toxic: Passed the GB/T 16422.3 harmful substance leaching test and met the drinking water standards.

Recyclable: HDPE materials support recycling and reuse, reducing the environmental burden.

Product Description:

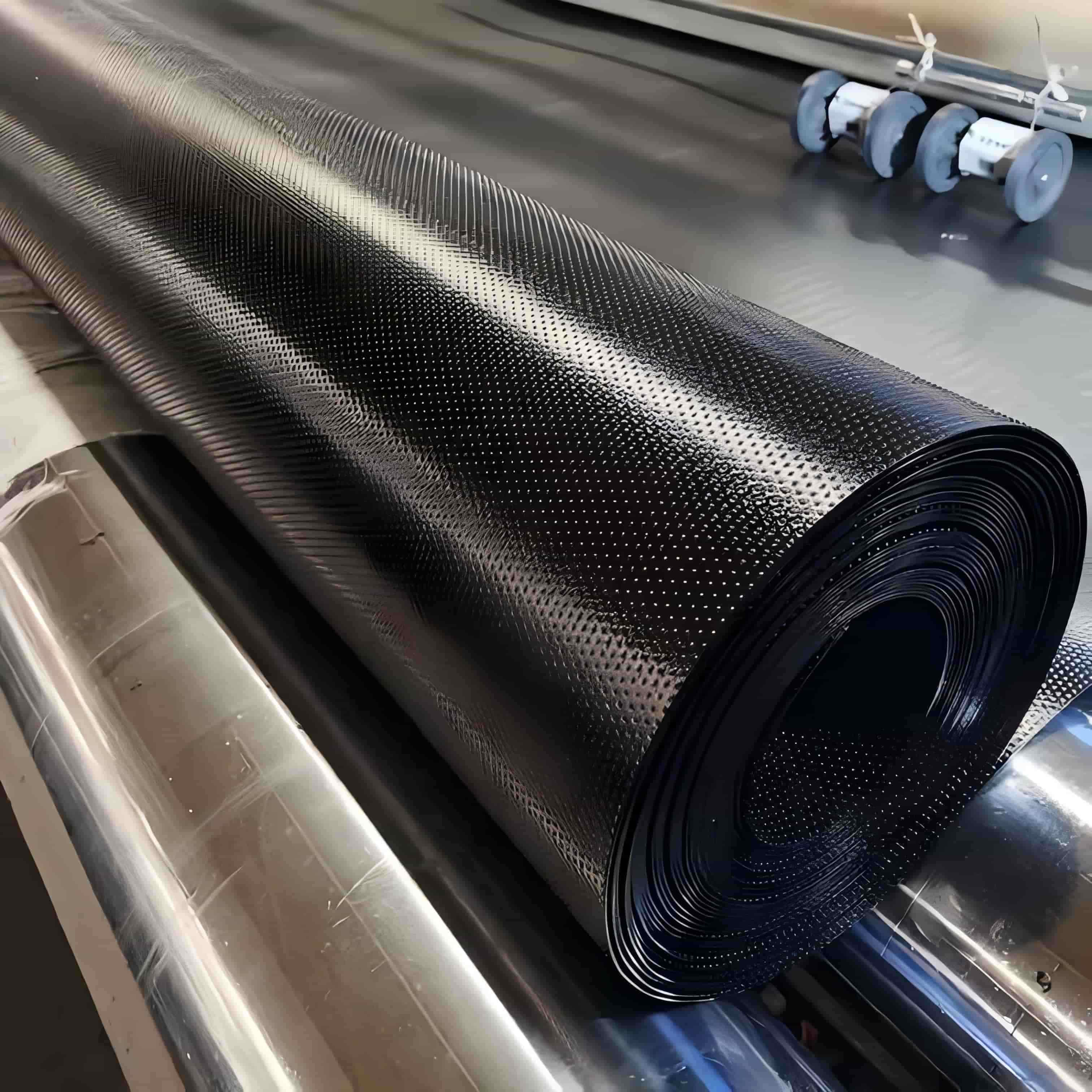

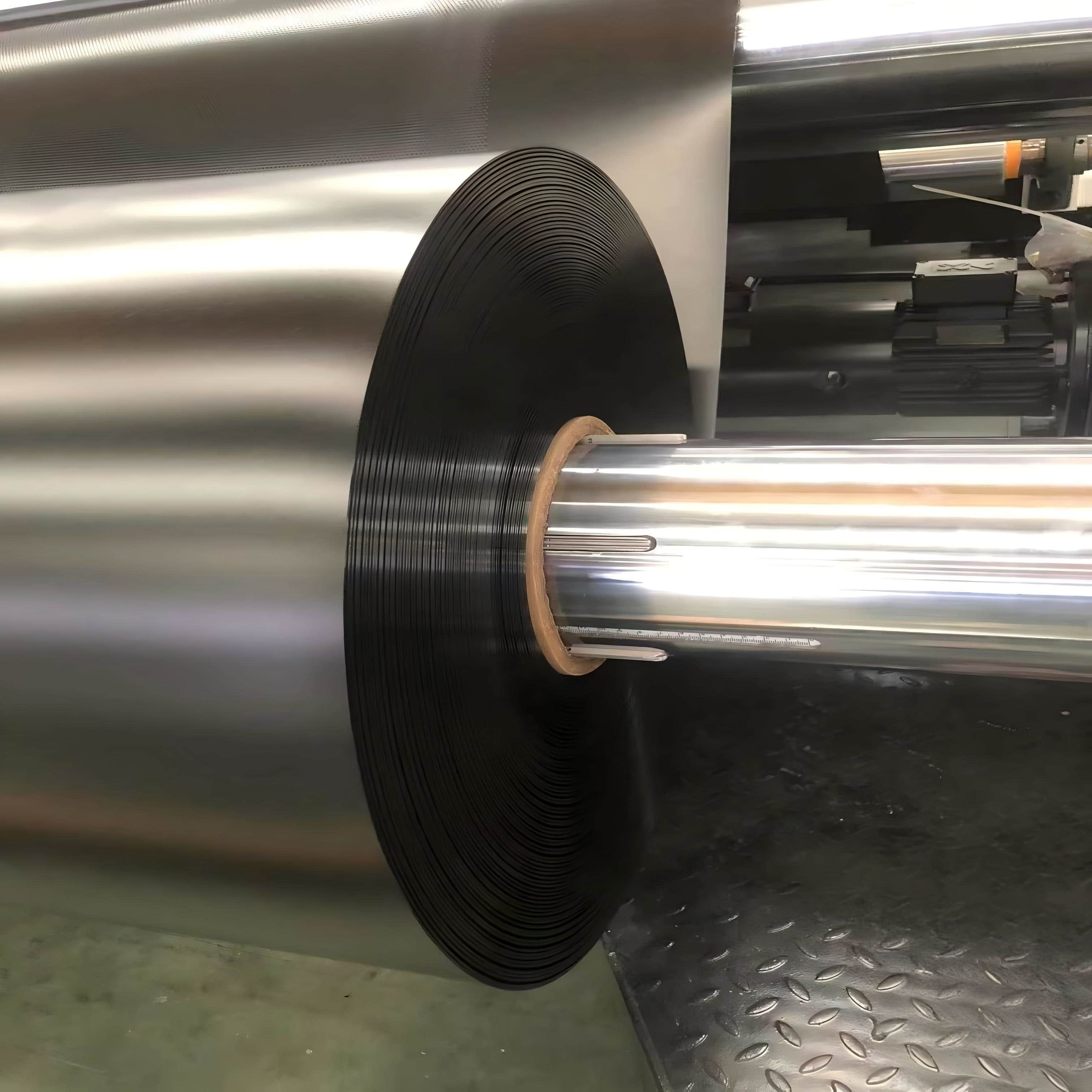

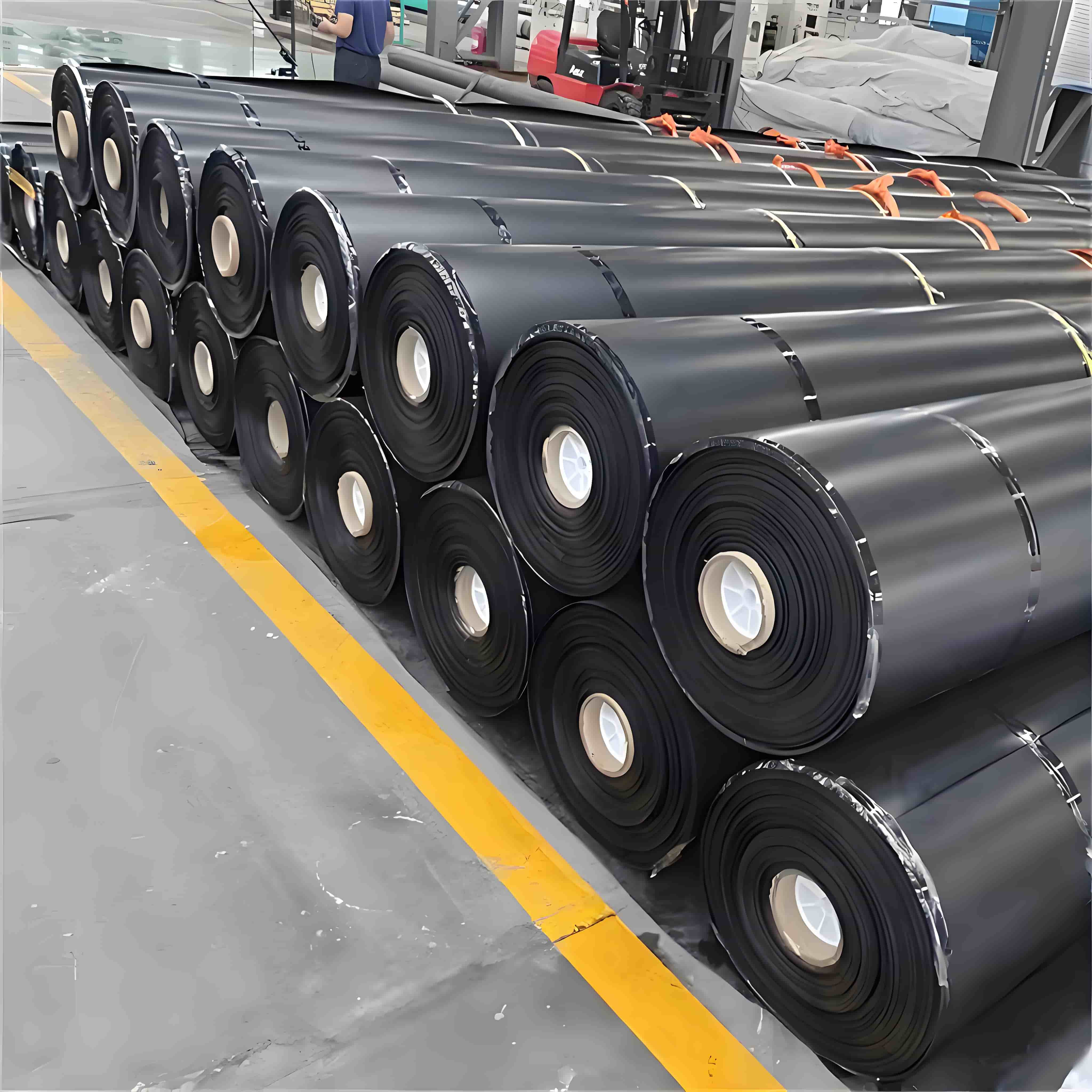

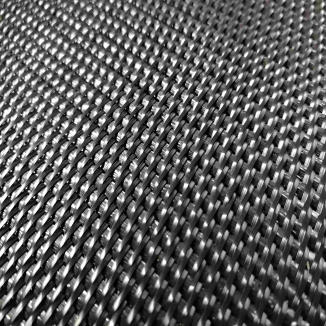

HDPE geomembrane is a flexible anti-seepage material made from high-density polyethylene resin through extrusion calendering or blow molding processes. It features excellent anti-seepage performance, chemical corrosion resistance and resistance to environmental stress cracking.

• Anti-seepage core: With a permeability coefficient as low as 1×10⁻¹³ cm/s, it can effectively prevent the penetration of liquids and contaminants.

• Strong weather resistance: Resistant to ultraviolet rays and high and low temperatures (-60℃ to 60℃), suitable for complex climate conditions.

• Chemical inertness: Resistant to corrosion by strong acids, strong alkalis, salts and organic solvents, suitable for harsh environments such as chemical plants and landfill sites.

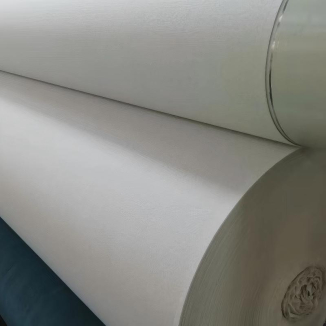

• Convenient construction: The roll form is easy to transport and lay, supports welding and splicing, and significantly shortens the construction period.

• Long service life: With the addition of dual anti-UV and anti-aging components, the service life can reach over 30 years.

Specifications:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Application field:

1. Environmental protection and municipal engineering

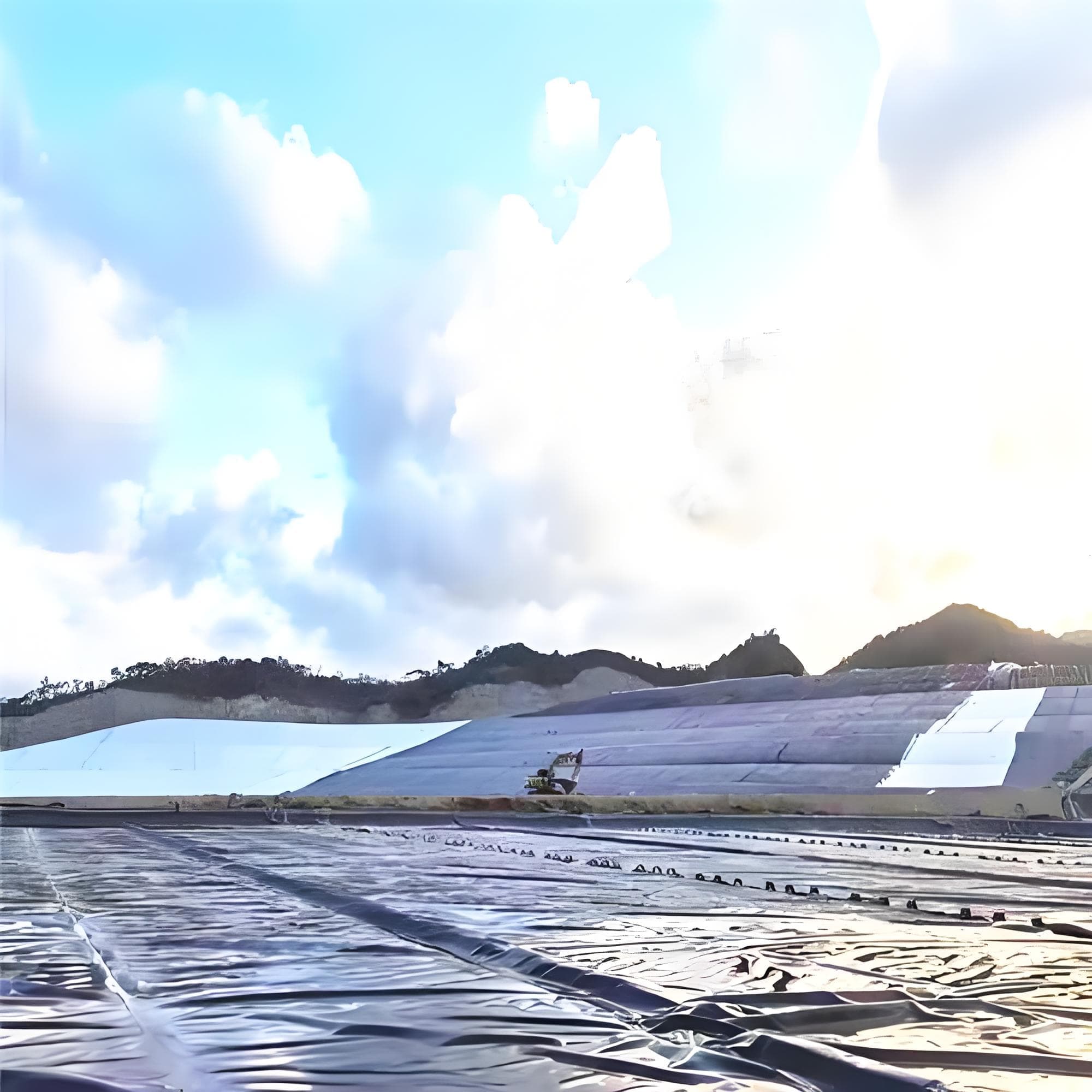

Landfill: As a base and covering anti-seepage layer, it prevents leachate from polluting groundwater.

Sewage treatment pool: Prevents sewage leakage and protects the surrounding soil and water sources.

Hazardous waste storage: It is used in high-risk scenarios such as hazardous waste temporary storage warehouses and nuclear waste isolation pools.

2. Water Conservancy and Agricultural Engineering

Reservoir/channel anti-seepage: Replace clay lining, reduce water resource loss, and improve irrigation efficiency.

Aquaculture: Build anti-seepage membranes for ponds to maintain water levels and prevent eutrophication pollution.

Constructed wetlands: As anti-seepage bases, they ensure the water purification function of the wetland system.

3. Mining and Energy Engineering

Tailings pond anti-seepage: Prevent the leakage of heavy metal solutions and reduce the risk of environmental pollution in mines.

Petroleum storage tank area: As a secondary anti-seepage layer, it intercepts the leakage and spread of oil products.

Red mud storage yard: Isolate strongly alkaline waste residue and protect the surrounding ecological environment.

4. Construction engineering

Underground engineering waterproofing: Anti-seepage for tunnel and basement roof slabs to prevent structural damage due to moisture.

Roof greening: Lightweight anti-seepage layer, taking into account both drainage and protection of plant roots.

Artificial lake/landscape water feature: Create a leak-free water body to reduce the cost of water replenishment.

5. Transportation Engineering

Subgrade anti-seepage: Waterproofing layer for highway and railway subgrades to prevent frost heaving and grouting diseases.

Slope anti-scouring: Cover the loose slope surface to reduce the risk of collapse caused by rainwater erosion.

6. Special industrial scenarios

Chemical plant floor: Acid resistant floor impermeable layer to prevent CHEMICAL leakage pollution.

Electrolytic cell gasket: Prevents electrolyte leakage and extends the service life of the equipment.