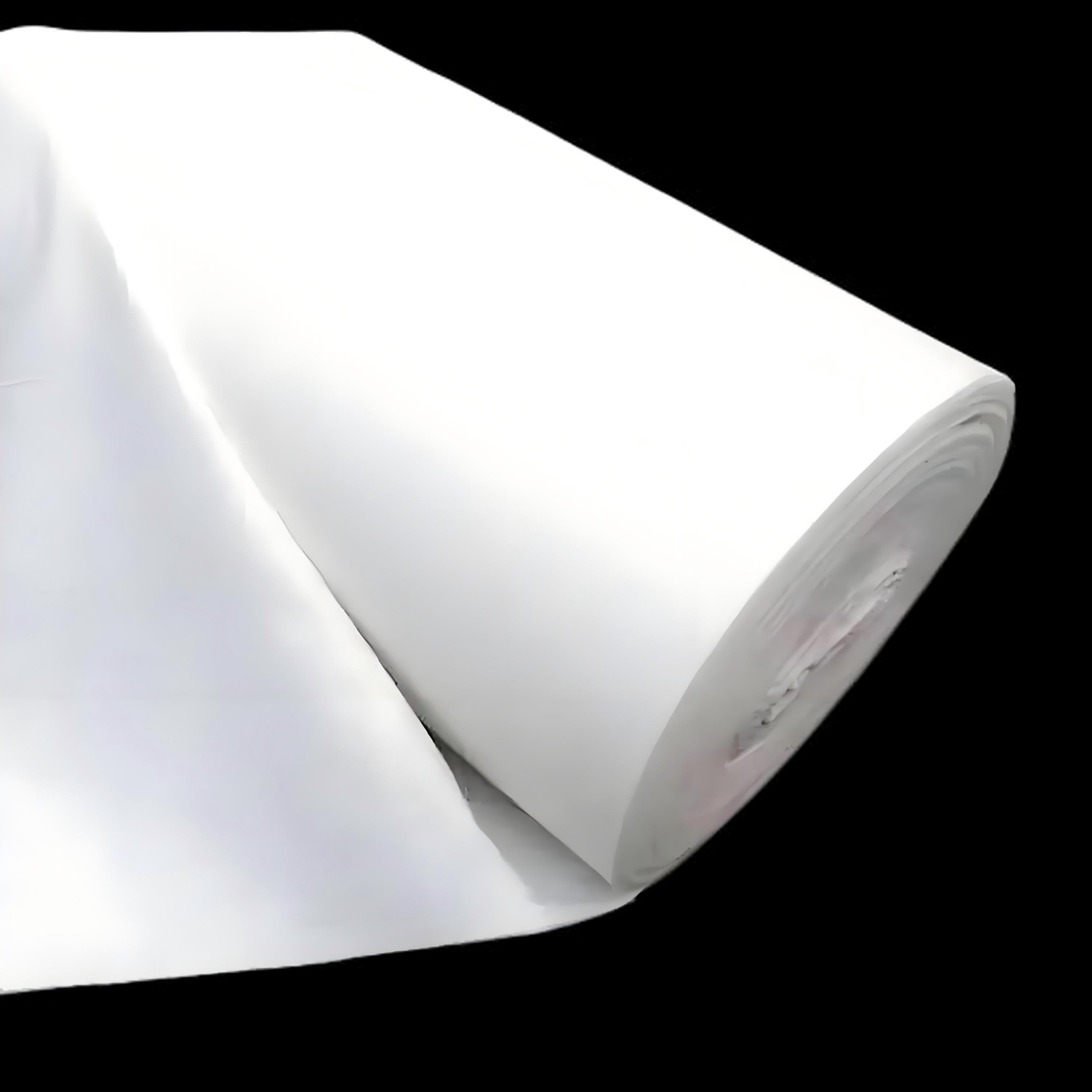

Nonwoven Geotextile

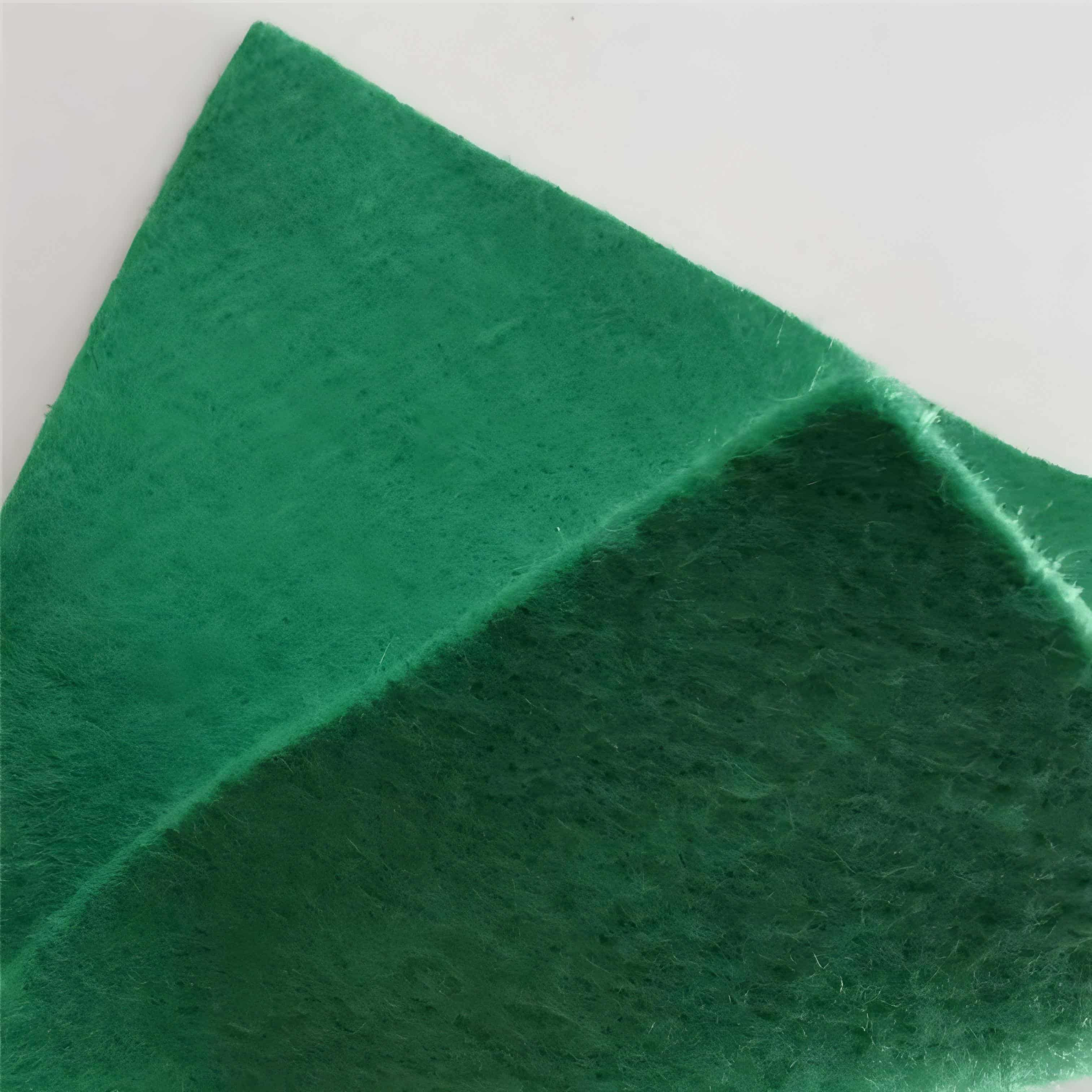

Nonwoven geotextile is a high-performance nonwoven material, made by needling polyester (PET) or polypropylene (PP) fibers.

It features high water permeability, anti-aging, and resistance to acid and alkali corrosion, among other core characteristics.

Its fiber structure can effectively isolate soil layers, filter sediment and enhance the stability of the foundation.

It is widely used in road engineering, landfill sites and environmental protection projects.

It complies with ISO 9001 quality certification and environmental protection standards and is an economical and efficient solution in infrastructure projects.

Nonwoven geotextile is a high-performance nonwoven material, made by needling polyester (PET) or polypropylene (PP) fibers.

I. Material and Process Characteristics

Fiber material and process

1. Polyester (PET) fiber: High strength (longitudinal tensile strength ≥15kN/m), resistant to ultraviolet aging, suitable for outdoor environments;

2. Polypropylene (PP) fiber: Resistant to acid and alkali (applicable from pH 1 to 14), anti-mold and antibacterial, suitable for damp or chemically contaminated sites;

3. Needling process: Fibers are randomly interwoven to form a three-dimensional pore structure, with a porosity of ≥75% and a water permeability of ≥0.2cm/s.

Physical parameters

1. Weight range: 100-800g/㎡ (customizable), lightweight design (thickness 1-5mm), convenient for transportation and laying;

2. Elongation at break: ≤50%, with both flexibility and tear resistance (tear strength ≥400N).

Specifications

| Item | Index | |||||||||

| Nominal Strength / (kN/m) | ||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | ||

| 1 | Longitudinal & Transverse Tensile Strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 |

| 2 | Longitudinal & Transverse Elongation at Maximum Load / % | 30~80 | ||||||||

| 3 | CBR Bursting Strength / kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 |

| 4 | Longitudinal & Transverse Tearing Strength / kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 |

| 5 | Equivalent Aperture Oos (Oos) / mm | 0.05~0.30 | ||||||||

| 6 | Vertical Permeability Coefficient / (cm/s) | K × (10⁻¹ ~ 10⁻³), where K = 1.0 ~ 9.9 | ||||||||

| 7 | Width Deviation Rate / % ≥ | -0.5 | ||||||||

| 8 | Mass per Unit Area Deviation Rate / % ≥ | -5 | ||||||||

| 9 | Thickness Deviation Rate / % ≥ | -10 | ||||||||

| 10 | Thickness Variation Coefficient (CV) / % ≤ | 10 | ||||||||

| 11 | Dynamic Perforation | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal & Transverse Breaking Strength (Grab Method) / kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 |

| 13 | Uv resistance performance (xenon arc lamp method) | Longitudinal and transverse strength retention rate /% ≥ | 70 | |||||||

| 14 | Uv resistance performance (fluorescent UV lamp method) | Longitudinal and transverse strength retention rate /% ≥ | 80 | |||||||

Ii. Functions and Advantages

High-efficiency filtration and drainage

It retains fine particles through fiber pores while allowing water to pass freely and preventing soil erosion (filtration efficiency ≥90%), and is suitable for roadbed drainage systems and river slope protection projects.

Isolation and protection performance

1. Prevent the mixing of different material layers (such as sand and soft soil) to reduce the risk of foundation settlement;

2. The puncture resistance strength is ≥300N, which can resist the penetration of plant roots and mechanical construction damage.

Resist environmental erosion

1. Passed the UV aging test (2000 hours intensity retention ≥85%), suitable for long-term outdoor use;

2. Temperature resistance range: -30℃ to 120℃, resistant to freeze-thaw cycles, suitable for extremely cold or hot regions.

Iii. Application Fields

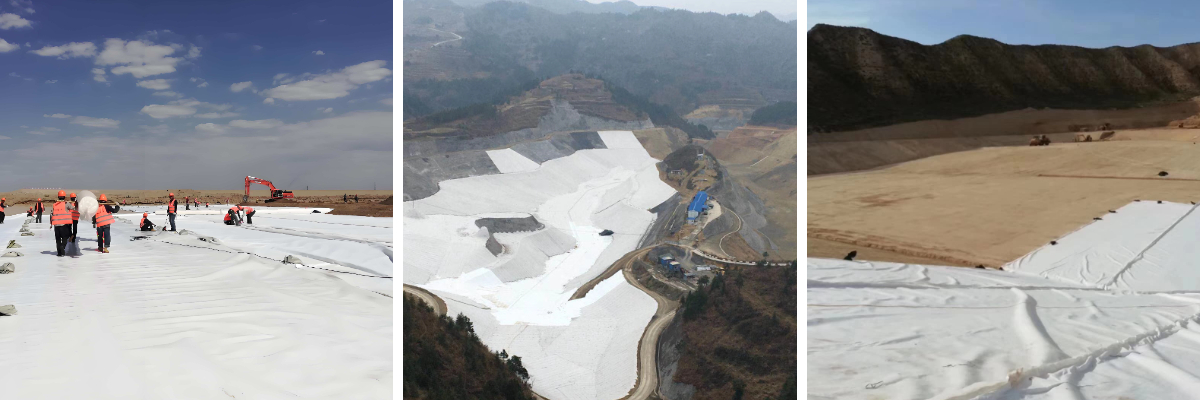

Civil and Transportation Engineering

1. Road isolation layer: soft foundation treatment, road/railway subgrade reinforcement;

2. Slope protection: reverse filtration of crushed stone slopes, bottom layer of reinforced soil retaining walls;

3. Landfill: Protective layer of anti-seepage system, leachate drainage.

Water conservancy and environmental protection engineering

1. Drainage system: Internal drainage of earth DAMS and water diversion for tunnel linings;

2. River channel management: Bank protection filter layer, ecological restoration base material;

3. Pollution prevention and control: Isolation of chemical sites, anti-seepage of tailings ponds.

Agriculture and municipal engineering

1. Farmland drainage: Prevent soil salinization and increase crop yields;

2. Roof greening: Construction of lightweight drainage layers;

3. Municipal facilities: Underground pipeline protection, road surface crack prevention and isolation.

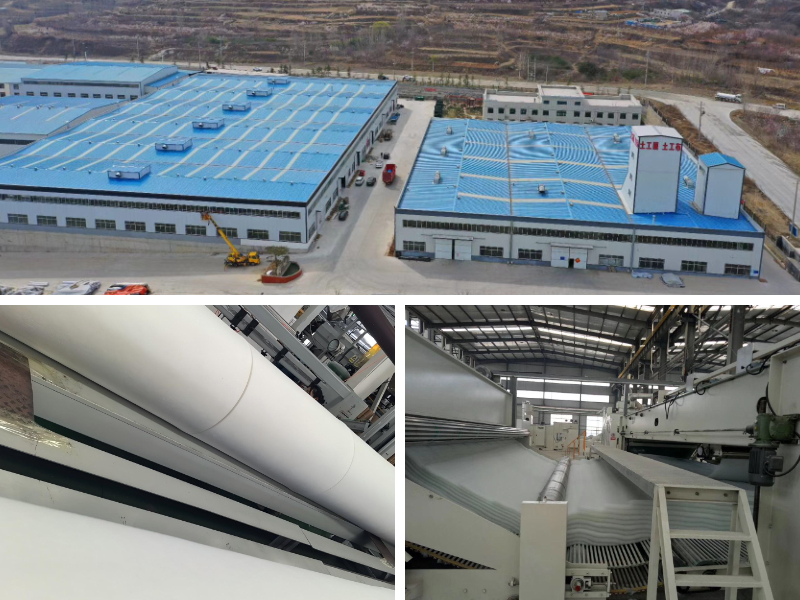

Iv. Environmental Protection and Certification

International certification

1.ISO 9001 quality management system, EU CE certification;

2. Passed the test standards of ASTM D4632 (tensile strength) and ASTM D4491 (water permeability).

Summary

Non-woven geotextiles, with three-dimensional water permeability and long-term stability as their core advantages, provide an integrated solution for efficient isolation, drainage and protection for infrastructure projects through the combination of scientific structure and environmentally friendly materials. Its wide adaptability (from road engineering to ecological restoration) and significant economic benefits (reducing construction costs by 30%) make it the preferred material in the global civil engineering field. In the future, it will be expanded to emerging scenarios such as sponge cities and Marine engineering, promoting the technological upgrade of green infrastructure.