Harga HDPE Geomembrane

1. Strong impermeability: It can effectively block the penetration of liquids and is commonly used for anti-seepage treatment in water conservancy, environmental protection and other engineering projects.

2. Good weather resistance: It can resist the influence of natural environments such as ultraviolet rays, high temperature, and low temperature, and has a long service life.

3. Simple structure: light weight, good flexibility, easy to lay and splice, can adapt to different terrains.

4. Excellent chemical stability: not easily corroded by acids, alkalis, etc., with a wide range of applications.

5. Relatively low cost: has good economic and engineering benefits.

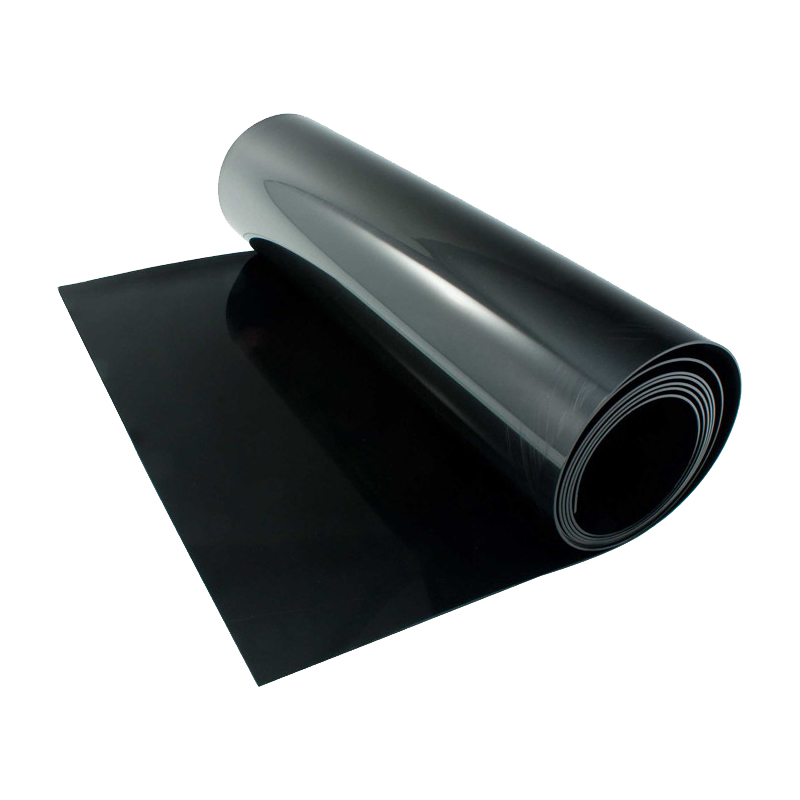

Product Introduction

Harga HDPE Geomembrane is a waterproof and barrier type geotextile material mainly made of polymer materials such as polyethylene PE, polyvinyl chloride PVC, ethylene vinyl acetate copolymer EVA, etc. Its core function is to prevent water, liquid or gas from penetrating.

It is usually divided into homogeneous films made of a single material (such as HDPE geomembrane) and composite films made of non-woven fabric. The former is widely used in high demand scenarios due to its high strength and chemical corrosion resistance, while the latter enhances puncture resistance and friction resistance through non-woven fabric, adapting to more complex construction environments.

Its main characteristics include: excellent anti-seepage performance (extremely low permeability coefficient), resistance to chemical corrosion such as acid and alkali, strong anti-aging ability, stable mechanical performance (able to adapt to foundation deformation), light weight, convenient construction, and can be cut and spliced according to project needs.

The application areas cover water conservancy engineering (dam and reservoir anti-seepage), environmental engineering (landfill and sewage treatment plant anti-seepage), transportation engineering (highway and railway foundation waterproofing), mining (tailings pond anti-seepage), agriculture (irrigation pond, breeding pond lining), etc. It is a key material for achieving anti-seepage and isolation in engineering.

Product Parameters

| Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

| test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

| Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

| Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

| minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

| Minimum average tensile performance (1) | D638 Type IV | |||||||||

| Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

| yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

| Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

| yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

| Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

| Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

| Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

| Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

| Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

| Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

| (a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

| (b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

| 85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

| (A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

| (B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

| Ultraviolet resistance (7) | Per formula | |||||||||

| (a) standard OIT | D3895 | Note (8) 50 | ||||||||

| (b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

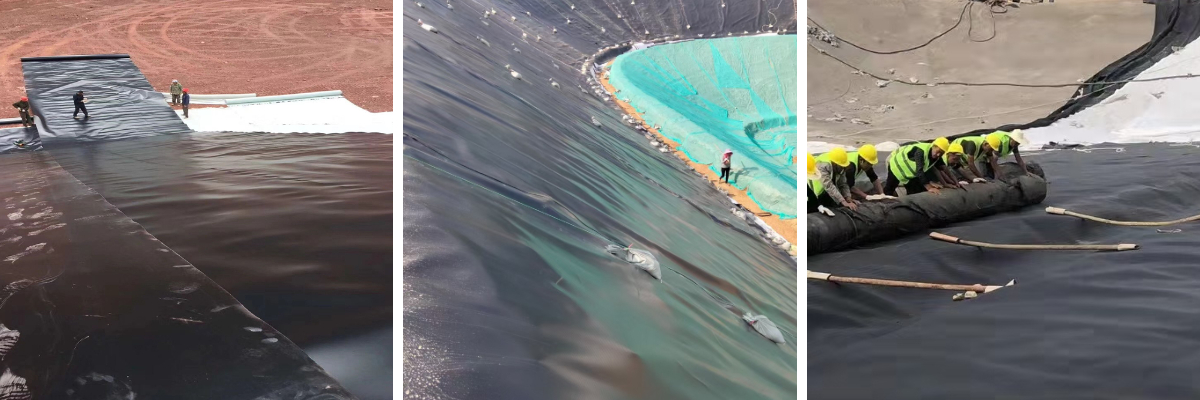

Product Application

Geomembrane, as a type of anti-seepage and barrier material with polymer as the core material, plays a key role in waterproofing and isolation in multiple engineering fields due to its excellent anti-seepage, corrosion resistance, and adaptability. It is an important material for ensuring engineering safety and environmental stability.

1. Water conservancy engineering: anti-seepage reinforcement of reservoirs and dams to prevent water leakage; The lining of water channels and artificial lakes can reduce water loss, especially in arid areas, and significantly improve water resource utilization efficiency.

2. Environmental protection engineering: the core of the anti-seepage system for landfills and hazardous waste disposal sites, which blocks the infiltration of leachate into soil and groundwater; The sedimentation tank and reaction tank of the sewage treatment plant are leak proof to prevent the diffusion of pollutants.

3. Transportation engineering: the waterproof layer of highway and railway subgrade to prevent groundwater from rising and eroding the foundation; The waterproof lining of tunnels and culverts ensures the durability of transportation facilities.

4. Mining and Agriculture: Bottom lining of tailings ponds and heap leaching ponds in mining to prevent slag wastewater pollution; The lining of water reservoirs and breeding ponds in agriculture reduces irrigation water loss and enhances the water retention capacity of aquaculture.

Different types of geomembranes (such as HDPE film, EVA film, etc.) will be selected according to the requirements of the scenario: HDPE film is often used in harsh environments such as landfills due to its high strength and corrosion resistance; EVA film has good flexibility and is suitable for projects with significant geological deformation. The core value of its application lies in its reliable anti-seepage performance, which balances engineering safety and environmental protection. It is an indispensable functional material in modern engineering.