Chinese Geotextile Tube Suppliers

1.Excellent material performance: It has the characteristics of resistance to ultraviolet radiation, chemical corrosion, and biological effects, and can play a long-term stable role in complex environments such as beach protection and industrial sludge treatment.

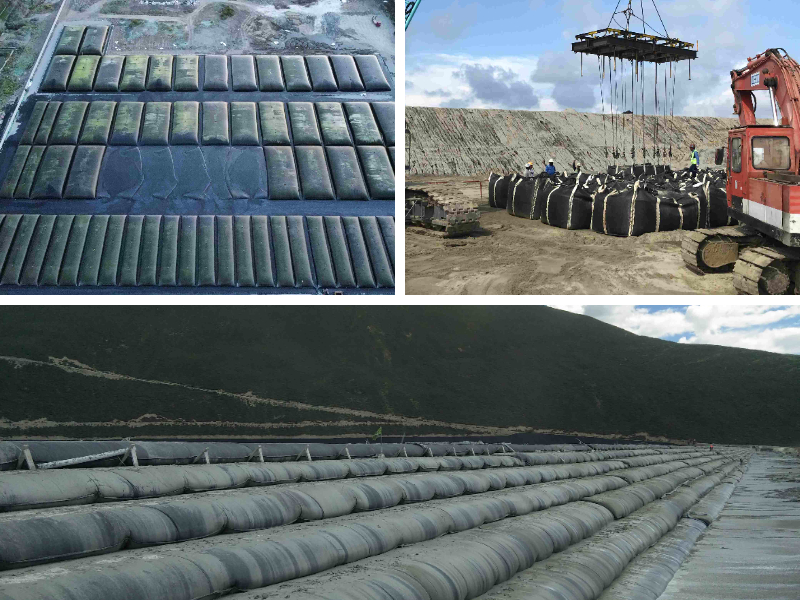

2.Convenient and efficient construction: using hydraulic filling method, with fast construction speed, can cope with emergency rescue projects; The process is simple, and ordinary personnel can operate it after training. It is also easy to transport and install after folding, adapting to different scenarios.

3.Flexible customization of size: able to accurately meet the design and site requirements of different projects.

4.Economic cost is controllable: local materials can be used to reduce transportation costs, and the processing unit price is low, which can save a lot of capital investment for the project.

5.Outstanding environmental performance: high solid retention rate, effectively reducing pollution, minimal damage to the surrounding ecology during construction.

Products Introduction:

As an innovative geotechnical material, Chinese Geotextile Tube play a crucial role in various engineering fields. It is made of high-performance materials such as high-strength polypropylene, with a unique structure and excellent performance, providing efficient, economical, and environmentally friendly solutions for many complex engineering problems.

The main structure of the geotextile tube is sewn with high-strength geotextile fabric. These geotextiles have special weaving techniques, and their pore sizes are precisely designed to effectively retain solid particles in the filling material while allowing moisture to seep out smoothly. When mud, silt or other filling materials are injected into the pipe bag through a high-pressure pump, water is discharged through the pores of the geotextile under the pressure difference and gravity, and solid particles gradually deposit and compact, causing the filling material inside the pipe bag to continuously solidify, ultimately forming a structure with certain strength and stability.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1.Embankment protection and reinforcement: Geotextile bags can be used to construct temporary or permanent embankments, enhancing their stability and resistance to erosion. In flood rescue, it can quickly fill and deploy, playing a role in blocking floods and protecting dam safety.

2.Sea reclamation and cofferdam engineering: In coastal land reclamation projects, geotextile bags are widely used in the construction of cofferdams. By connecting and stacking the pipe bags together, a sturdy cofferdam structure is formed, providing a reliable foundation for subsequent land reclamation operations.

3.River regulation and flood control engineering: In river regulation, geotextile bags can be used to reinforce river slopes, repair damaged riverbanks, prevent soil erosion and riverbank collapse. At the same time, by adjusting the direction of water flow, the water flow conditions of the river can be improved, and the flood control capacity of the river can be enhanced.

4.Sludge treatment and disposal: Whether it is sludge generated by municipal sewage treatment plants or various types of sludge generated in industrial production processes, geotextile bags can play an important role. By filling high water content sludge into tube bags for dewatering treatment, the volume of sludge can be effectively reduced, and the difficulty and cost of subsequent disposal can be lowered. Dehydrated sludge can be further utilized as a resource, such as for making building materials, soil amendments, etc.

5.Polluted sediment treatment: Polluted sediment in rivers, lakes, and seas is an important factor affecting the quality of water environment. Geotextile bags can be used to collect and treat these polluted sediment. Through processes such as dehydration and solidification, harmful substances in the sediment are fixed to prevent their re release into the water body, thereby achieving the goal of purifying the water environment.

6.Ecological restoration engineering: In ecological engineering such as wetland protection and beach restoration, geotextile bags can be used as an eco-friendly material to construct artificial coastlines and protect wetland ecosystems. The filling material inside the tube bag can provide nutrients and support for plant growth, promote vegetation recovery and growth, and thus improve the ecological environment.

7.Agriculture and Animal Husbandry: In large-scale poultry and livestock farming, a large amount of livestock manure and sewage discharge have caused serious pressure on the environment. Geotube bag technology can effectively separate solid and liquid waste from livestock and poultry breeding. By filling the mixture of animal manure and sewage into a tube bag and utilizing the filtering effect of the tube bag, solid matter is intercepted and water that meets discharge standards is filtered out. After solidification, solid materials can be used as organic fertilizer raw materials for subsequent processing, achieving the resource utilization of waste.

8.Recycling and utilization of mining waste: Mines and beneficiation plants generate a large amount of waste rock and tailings during the production process, which not only occupy a large amount of land but also cause serious pollution to the environment. Geotextile bags can be used to recycle waste materials from mining and beneficiation processes, by filtering and dehydrating valuable metals to achieve resource recycling and reduce the harm of waste to the environment.

9.Dehydration pretreatment of construction waste: A large amount of construction waste generated during urban construction activities, such as cement slurry, shield tunneling slurry, etc., usually has a high water content, is difficult to transport, and can easily cause secondary pollution. Geotextile bags can be dehydrated and pre treated before transportation of construction waste to reduce their moisture content, facilitate transportation and subsequent disposal, and reduce their impact on the environment.

In summary, geotextile bags have demonstrated irreplaceable value in many engineering fields such as water conservancy, environmental protection, and municipal engineering due to their strong durability, efficient and convenient construction methods, flexible customization capabilities, significant economic benefits, and outstanding environmental attributes. It not only provides efficient solutions for various complex projects, but also plays an important role in reducing costs and protecting the ecological environment. It is an ideal material with great potential in modern engineering construction.