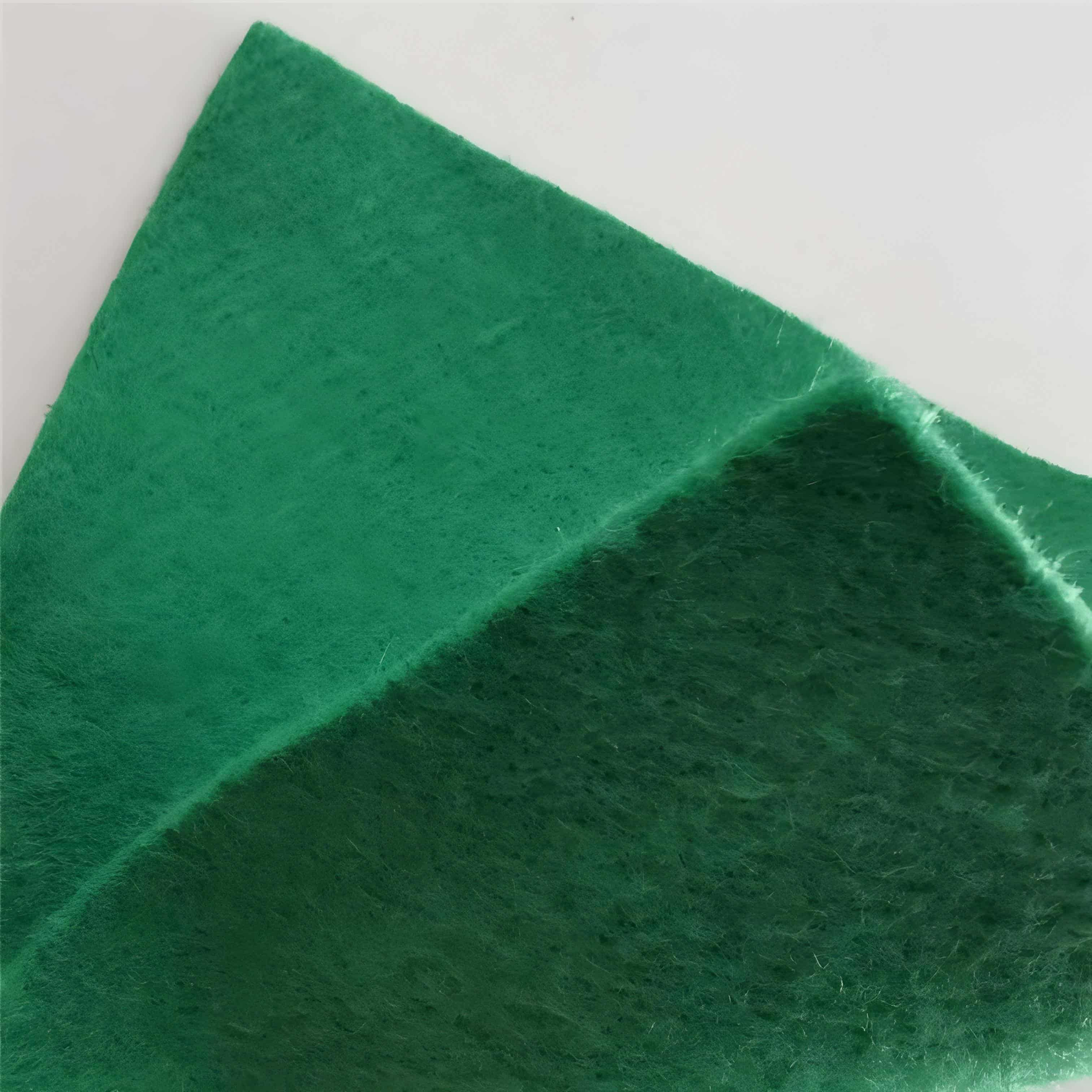

8 oz Needle Punch Filter Fabric

1.Accurate filtration: Uniform pores efficiently intercept small impurities, with stable accuracy.

2.Smooth drainage: Needle punched pores reduce resistance, filter while ensuring smooth water flow.

3.Durable and strong: Resistant to tearing and stretching, acid and alkali, suitable for complex working conditions.

4.Convenient construction: Flexible and easy to cut, fits the base layer, suitable for multiple scenarios.

Product Introduction

1、 Basic attributes

8 oz Needle Punch Filter Fabric is a geotextile filter material made from polymer fibers such as polypropylene and polyester, processed through needle punching technology. 8 ounces "represents its unit area weight, which forms a uniform and stable three-dimensional pore structure. The fabric material is flexible and has a certain thickness, with good overall chemical stability, and can adapt to filtration needs in various environments.

2、 Core functions

Precise filtration interception: With uniform pore distribution, it can efficiently intercept small particles and impurities in water or soil, such as sediment, suspended particles, etc., ensuring the cleanliness of the filtered medium and maintaining the normal operation of the filtration system.

Ensure smooth water flow: The connected pores formed by the needle punching process can achieve efficient filtration while reducing the resistance of water flow, ensuring the smooth passage of moisture or other fluids, and avoiding the impact of filter material blockage on the drainage or transportation efficiency of the system.

3、 Main features

High structural strength and durability: The needle punching process intertwines and reinforces the fibers, endowing the fabric with outstanding tear and tensile resistance, as well as good acid and alkali corrosion resistance. It can be used stably for a long time under complex working conditions, extending its service life.

Strong adaptability to construction and scene: The texture is flexible, easy to cut and process, and can be laid according to different engineering needs to fit various base surfaces. It is widely suitable for various scenarios such as dam filtration in water conservancy projects and sewage treatment filtration in environmental protection projects.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Application

1、 Water conservancy engineering field

In hydraulic engineering, 8-ounce needle punched filter cloth has important applications. In the process of dam construction, it is often laid between the anti-seepage layer of the dam and the soil, which can effectively intercept small particles in the soil, prevent these particles from entering the anti-seepage layer with water flow, avoid the anti-seepage layer being blocked and affecting the anti-seepage effect, and ensure that the water inside the dam can be smoothly discharged, maintaining the stability of the dam structure. In addition, in river regulation projects, this filter cloth can be used for filtering and drainage of river slopes, reducing the erosion of slope soil by water flow and protecting the integrity of river slopes.

2、 Environmental engineering field

Environmental engineering is a key application scenario for 8-ounce needle punched filter cloth. In sewage treatment engineering, it can be used as a primary filtering material, laid in the filtering layer of the sewage treatment tank, efficiently intercepting suspended particles, sediment and other impurities in the sewage, reducing the burden of subsequent sewage treatment processes, and improving the efficiency and quality of sewage treatment. In landfill engineering, filter cloth is laid on top of the anti-seepage system at the bottom of the landfill, which can filter solid particles in the leachate, prevent these particles from blocking the drainage channels of the anti-seepage system, ensure the smooth collection and treatment of leachate, and reduce environmental pollution.

3、 Transportation engineering field

The 8-ounce needle punched filter cloth also plays an important role in transportation engineering. In highway construction, it is used for filtering and draining the roadbed, laid between the roadbed fill and the drainage layer, to prevent soil particles from entering the drainage layer, avoid blockage of the drainage layer, ensure timely drainage of accumulated water inside the roadbed, reduce problems such as roadbed settlement and deformation caused by accumulated water, and extend the service life of the highway. In the treatment of track subgrade in railway engineering, filter cloth can isolate fillers of different particle sizes while allowing moisture to permeate and be discharged, maintaining the structural stability of the track subgrade.

4、 Municipal construction field

Municipal construction cannot do without the support of 8-ounce needle punched filter cloth. In urban underground drainage pipeline engineering, filter cloth is wrapped around the backfill material around the drainage pipeline, which can filter out soil particles that enter the backfill material, prevent the backfill material around the pipeline from being blocked, and ensure smooth drainage of the drainage pipeline. In the construction of artificial lakes and landscape water pools in urban greening projects, it can be laid between the anti-seepage layer at the bottom of the pool and the soil, playing a filtering role, preventing soil particles from damaging the anti-seepage layer, and ensuring the drainage performance of the pool.

In summary, 8-ounce needle punched filter cloth has important and widespread applications in various engineering fields such as water conservancy, environmental protection, transportation, and municipal engineering due to its precise filtering and interception ability, good water flow smoothness, high structural strength, and wide adaptability. It provides reliable guarantees for the structural stability and normal operation of various projects by effectively filtering impurities and ensuring smooth drainage, while extending the service life of the projects and reducing maintenance costs. It has irreplaceable practical value in engineering construction.