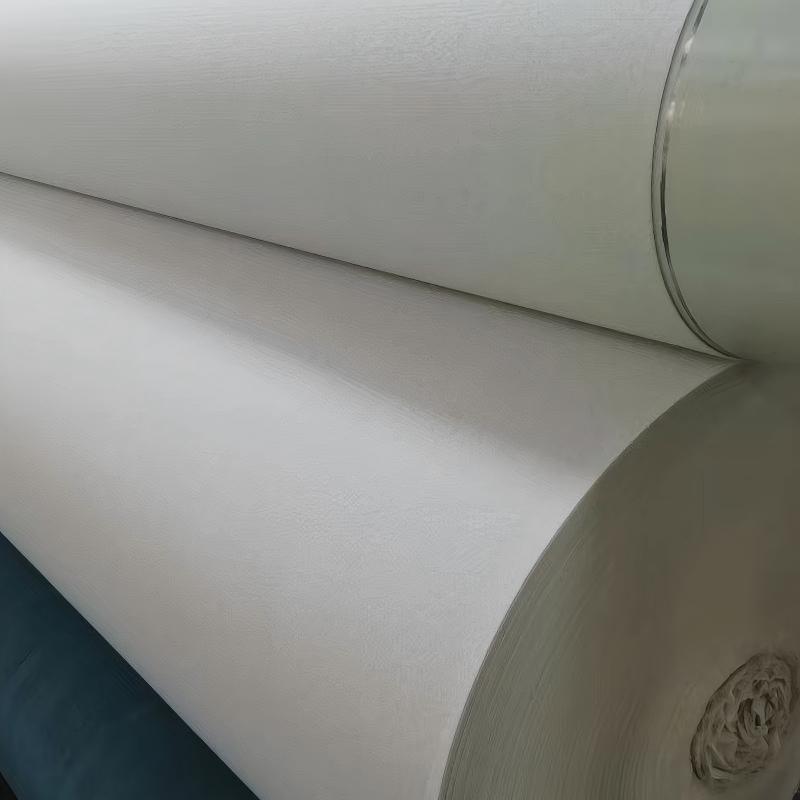

Geotech Non Woven Filter Fabric

1.Efficient filtration, soil retention and permeability:The unique fiber structure accurately intercepts soil particles to prevent loss, while ensuring smooth water infiltration and stable soil structure.

2.Durable and damage resistant, with strong adaptability:High strength materials are resistant to stretching, tearing, acid, alkali, and ultraviolet radiation, and can be used for a long time in diverse climates and geological environments.

3.Easy construction and lower cost:The material is lightweight and flexible, easy to lay, cut, and assemble, suitable for irregular construction surfaces, reducing waste and overall costs.

4.Widely applicable, scene adaptation:Covering fields such as water conservancy, highways, environmental protection, agriculture, etc., it meets diverse needs such as dam filtration, roadbed drainage, and anti-seepage filtration.

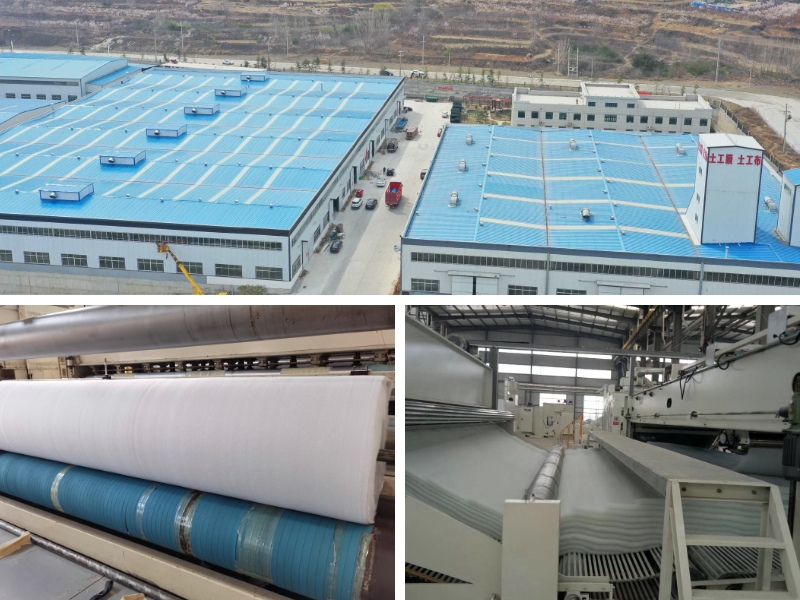

Product Introduction

1、 Basic attributes

Geotech Non Woven Filter Fabric are made from high molecular weight polymers such as polypropylene and polyester through processes such as spinning, mesh laying, and bonding. The overall material is lightweight, typically weighing between 100-600 grams per square meter, making it easy to transport and handle; At the same time, it has excellent flexibility and can be bent and folded freely without easily breaking. Its unique three-dimensional fiber structure forms a large number of uniformly distributed micropores, with a porosity of over 70%, providing a solid structural foundation for filtration function. In addition, the material itself has excellent tensile strength (longitudinal tensile strength can reach 10-30kN/m) and tear resistance, which can easily cope with external forces such as pulling and rolling during construction, and adapt to long-term use needs in different climates and geological environments.

2、 Core functions

The core function focuses on the dual role of efficient filtration and soil and water conservation. In terms of filtration, with precise pore size design (usually 0.01-0.1mm), it can effectively intercept solid impurities such as soil particles, sand, and gravel with diameters larger than the pores, preventing soil structures from being washed away by water flow; At the same time, the microporous structure ensures smooth infiltration of fluids such as water and air, avoiding the problem of water accumulation and blockage. At the level of soil and water conservation, by stabilizing the distribution of soil particles, reducing the damage to soil structure caused by factors such as rainwater erosion and water flow impact, and maintaining the stability of engineering structures such as roadbeds and dams, it plays a key role in filtration and drainage in water conservancy irrigation, highway construction, environmental protection and anti-seepage projects.

3、 Main features

Strong durability: The material itself has good chemical stability, can withstand acid and alkali corrosion, microbial erosion, and has a certain ability to resist UV aging. It is not easy to suffer from brittleness, degradation, and other problems when used in outdoor environments for a long time. Even in complex geological environments with large temperature differences and high humidity, stable physical properties and filtration effects can be maintained, and the service life can reach 5-10 years or more.

Convenient construction: The texture is soft and lightweight, and the laying process does not require large mechanical equipment, making it easy to complete manually. The material cutting is convenient and can be flexibly adjusted according to the shape and size of the construction surface. When splicing, tight connections can be achieved through methods such as hot melt and stitching, which can adapt well to various irregular construction terrains and reduce material loss and project delays during the construction process.

Cost controllable: Compared with traditional materials such as sand and gravel filter layers and woven filter fabrics, geotextile non-woven filter fabrics have lower raw material and production processing costs, and relatively lower transportation and storage costs. Low labor input and high efficiency during construction can effectively reduce overall construction costs and maximize economic benefits while ensuring project quality.

Widely applicable: With excellent filtration, drainage, and protection performance, it is widely used in dam filtration and channel anti-seepage in water conservancy engineering; Roadbed drainage and slope protection in highway and railway engineering; Anti seepage and sewage treatment filtration in landfill sites in environmental protection engineering; Multiple fields such as soil and water conservation, irrigation system filtration, etc. in agricultural engineering meet diverse functional requirements in different engineering scenarios.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

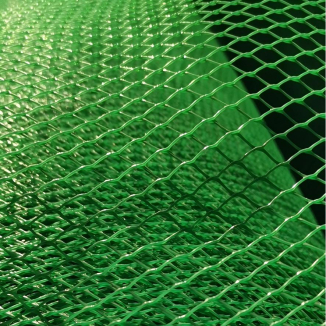

Product Application

1、 Water conservancy engineering: Strengthening the safety defense line of dams and channels

In hydraulic engineering, geotextile non-woven filter fabric is the core material for dam filtration and channel anti-seepage. In dam construction, it is laid on the contact surface between the dam body and the foundation, which can effectively intercept soil particles in the dam body, prevent dam leakage or collapse caused by water flow erosion, and ensure the smooth discharge of seepage water, maintaining the stability of the dam structure. In channel engineering, the filter fabric laid on the slope and bottom of the channel can reduce the erosion of the inner wall of the channel by water flow, prevent soil erosion, extend the service life of the channel, and improve irrigation and water delivery efficiency.

2、 Highway and railway engineering: ensuring stable roadbed and smooth drainage

The construction of roadbeds for highways and railways cannot be separated from the support of geotextile non-woven filter fabrics. It is widely used in roadbed drainage systems, laid between roadbed filling and drainage layers. It can intercept fine particles in the roadbed soil, prevent them from blocking drainage channels, and allow accumulated water in the roadbed to quickly infiltrate and drain, reducing soil moisture content and preventing roadbed settlement, grouting and other diseases. In addition, in slope protection engineering, filter fabrics can be used in conjunction with other protective materials to enhance slope stability and reduce soil erosion caused by rainwater erosion.

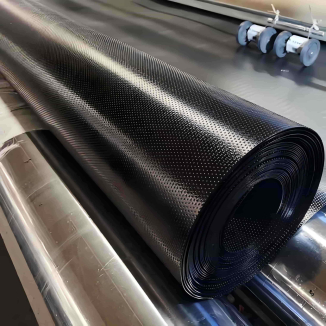

3、 Environmental engineering: strengthening anti-seepage and filtration purification functions

In environmental engineering, geotextile non-woven filter fabrics play an important role in landfill sites and sewage treatment. In landfills, it serves as an auxiliary material for the anti-seepage system, laid between the anti-seepage membrane and the soil. It not only protects the anti-seepage membrane from sharp object punctures, but also prevents soil particles from entering the anti-seepage layer and affecting the anti-seepage effect through filtration, while assisting in the discharge of leachate from the landfill. In sewage treatment, filter fabrics can be used as filtering media to intercept suspended impurities and solid particles in sewage, improve sewage purification efficiency, and reduce the difficulty of subsequent treatment.

4、 Agricultural Engineering: Assisting in Soil and Water Conservation and Irrigation Optimization

In agricultural production, geotextile non-woven filter fabrics are widely used in soil and water conservation and irrigation systems. In the construction of farmland slopes and terraced fields, laying filter fabrics can effectively reduce the erosion of soil by rainwater, prevent soil loss, and protect arable land resources. In the irrigation system, it is installed at the inlet or filter of the irrigation pipeline to filter out sediment, debris, etc. in the water, avoid clogging of irrigation equipment, ensure irrigation uniformity, improve water resource utilization efficiency, and reduce equipment maintenance costs caused by impurity blockage.

Geotextile non-woven filter fabric has become an indispensable key material in various engineering fields such as water conservancy, highway and railway, environmental protection, agriculture, etc. due to its efficient filtration performance, stable physical properties, and wide adaptability. It not only enhances the safety and stability of the project by intercepting impurities, ensuring permeability, and stabilizing the structure, but also reduces construction and maintenance costs, providing reliable guarantees for the smooth implementation and long-term operation of various projects, fully demonstrating its important value in infrastructure construction and ecological protection.