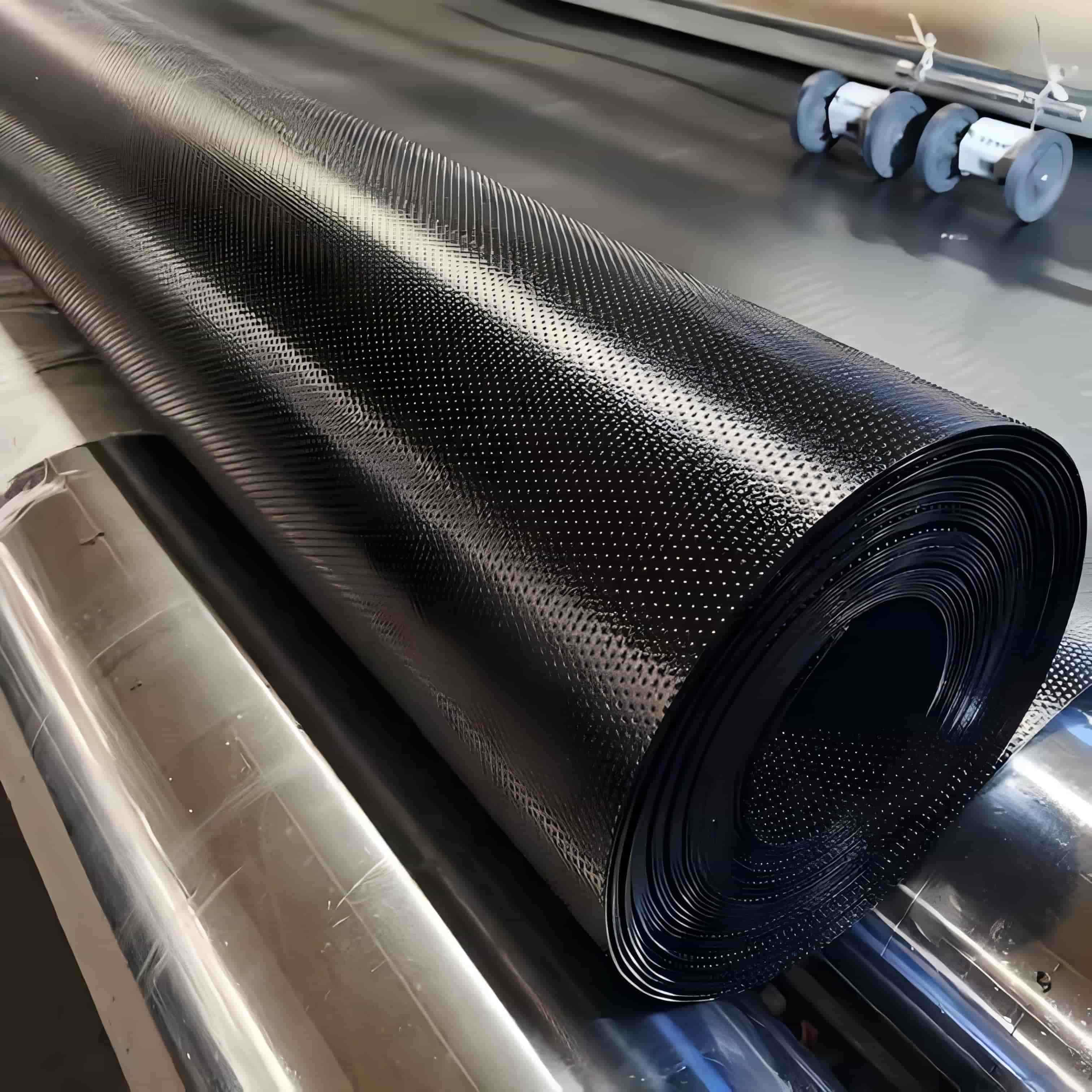

30 mil Geomembrane Liner

1. High anti-seepage efficiency: Compared with traditional anti-seepage materials such as clay and concrete, the anti-seepage effect is improved several times to tens of times, which can significantly reduce the risk of leakage.

2. Cost controllable: The material unit price is moderate, and the construction period is short with less maintenance in the later stage, resulting in a lower overall cost than traditional anti-seepage solutions.

3. Good environmental friendliness: Made of non-toxic polymer materials, it has no pollution to soil and water bodies, and some products can be recycled and reused, meeting green engineering standards.

4. Wide adaptability: not limited by geological conditions or climate environment, it can be used stably in various scenarios such as drought, humidity, salt alkali, etc.

Product Introduction:

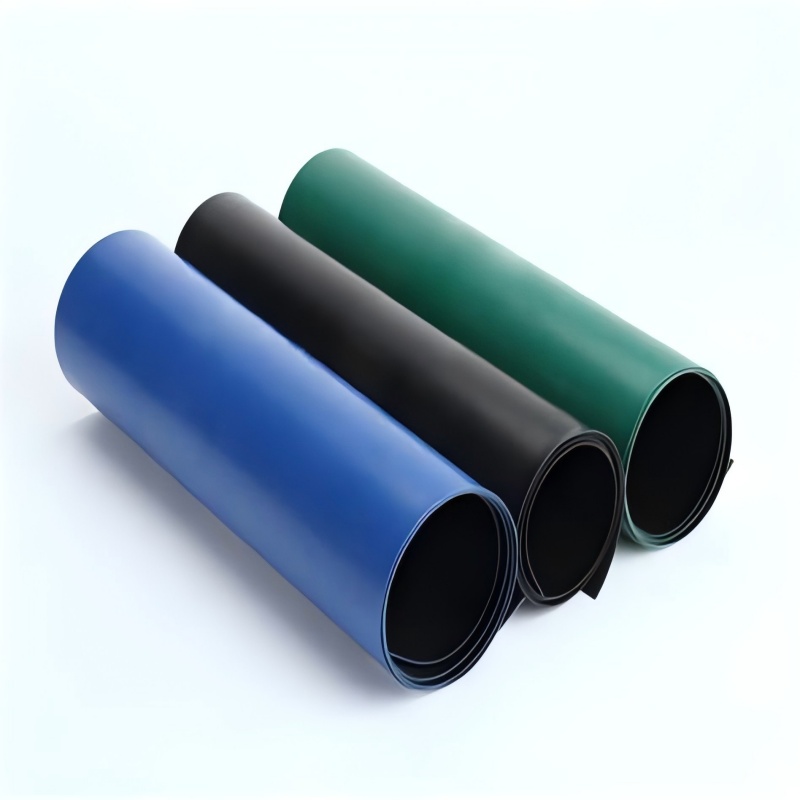

30 mil Geomembrane Liner is a flexible waterproof barrier material made from high molecular weight polymers such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyvinyl chloride (PVC), etc., through high-temperature melting, extrusion, or blow molding processes. Its core function is to prevent the penetration of liquids, gases, or solid particles through physical barriers, and it is widely used in engineering scenarios that require anti-seepage, isolation, or enhancement.

characteristic

1. Super strong anti-seepage performance

The anti-seepage coefficient is as low as 1 × 10 ⁻¹⁷ cm/s, which can effectively intercept the infiltration of water, chemicals, and even gases. For example, in landfills, HDPE geomembranes can prevent leachate from polluting groundwater, and the anti-seepage effect is hundreds of times that of traditional clay layers.

2. Weather resistance and chemical stability

Suitable for a wide temperature range (-70 ℃ to 110 ℃), it can resist UV rays, ozone, and oxidation, and has stable performance for long-term exposed use.

Resistant to strong acid, alkali, and oil corrosion, it is an ideal anti-corrosion material for chemical storage tanks, tailings ponds, and other scenarios.

3. High tensile strength and adaptability

The tensile strength of HDPE geomembrane can reach 17-25 MPa, which can adapt to uneven geological settlement and avoid rupture caused by foundation deformation.

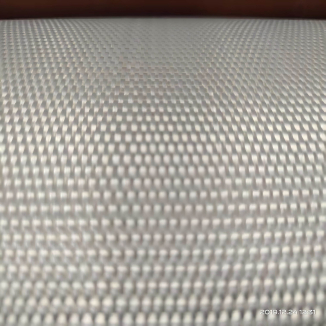

Composite geomembrane (one fabric one membrane or two fabrics one membrane) is reinforced with geotextile to further enhance its puncture and tear resistance, and is suitable for rock filling or mechanical operation areas.

4. Environmental protection and construction convenience

The material is non-toxic, odorless, and meets environmental requirements. It can be directly used in scenarios such as drinking water tanks and aquaculture ponds.

The construction period is short, and can be quickly installed using methods such as hot melt welding, adhesive bonding, or mechanical fixation. It is also lightweight (about 0.5-3kg per square meter), making it easy to transport and lay.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Applications:

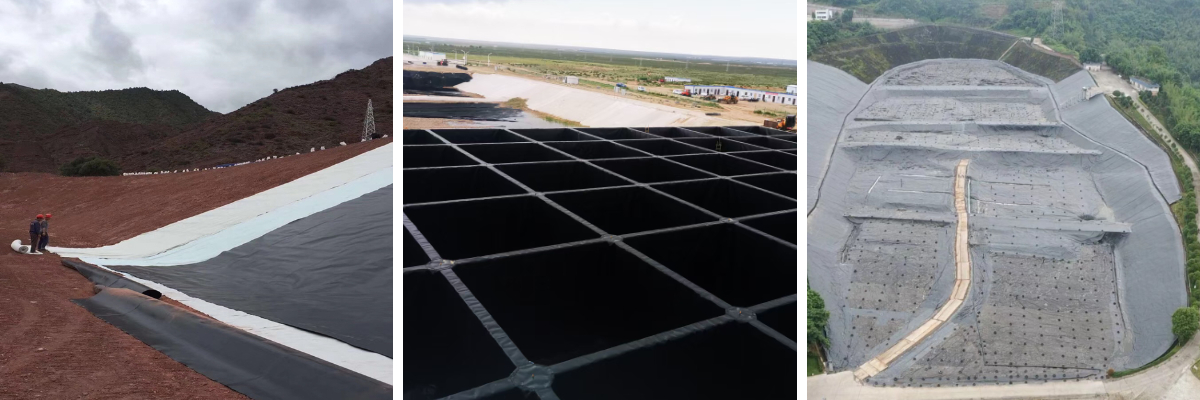

1. Water conservancy engineering

River bank protection: to prevent the collapse of bank slopes caused by water flow erosion, such as the use of geomembranes to reinforce embankments in the Yellow River control project.

Reservoir anti-seepage: replacing traditional clay core walls to reduce leakage. For example, the use of HDPE geomembrane in some areas of the Three Gorges Reservoir has reduced the leakage rate by over 90%.

Canal lining: Improve water delivery efficiency, reduce evaporation and leakage losses.

2. Environmental Engineering

Landfill site: As an anti-seepage liner for the bottom and slope, it prevents leachate from contaminating soil and groundwater. For example, the Shanghai Laogang landfill uses a double-layer HDPE geomembrane system to ensure long-term anti-seepage effect.

Sewage treatment tank: prevent sewage leakage and protect the surrounding environment.

3. Mining and Energy

Tailings dam: isolates tailings from the external environment to avoid heavy metal pollution. For example, the tailings pond of Zijin Mining uses a composite structure of geomembrane and geotextile to meet environmental protection requirements.

Oil storage tank anti-seepage: In gas stations and chemical plants, geomembranes are used as secondary anti-seepage layers to prevent oil leakage.

4. Agriculture and Landscape Architecture

Aquaculture: lined fish ponds and shrimp ponds to maintain clean water quality and prevent soil erosion. For example, after using geomembranes in shrimp aquaculture ponds, the disease rate decreased by 30% and the yield increased by 20%.

Artificial lakes and golf courses: constructing landscape water bodies to prevent water infiltration and ground collapse.

5. Transportation and Architecture

Highway and railway subgrade reinforcement: reduce soft soil foundation settlement and improve road stability. For example, some sections of the Qinghai Tibet Railway use geomembranes to enhance the roadbed in permafrost areas.

Underground engineering waterproofing: As a waterproofing membrane in subways and tunnels, it is combined with concrete structures to form dual protection.

6. Salt Industry and Special Engineering

Salt field crystallization pool: prevents brine leakage and improves salt production efficiency. For example, after using geomembranes in Shouguang Salt Field, Shandong, the utilization rate of brine increased by 15%.

Biogas digester: a sealed fermentation tank that collects biogas and prevents gas leakage.

Geomembranes have become an indispensable material in modern engineering due to their reliable anti-seepage performance and adaptability.