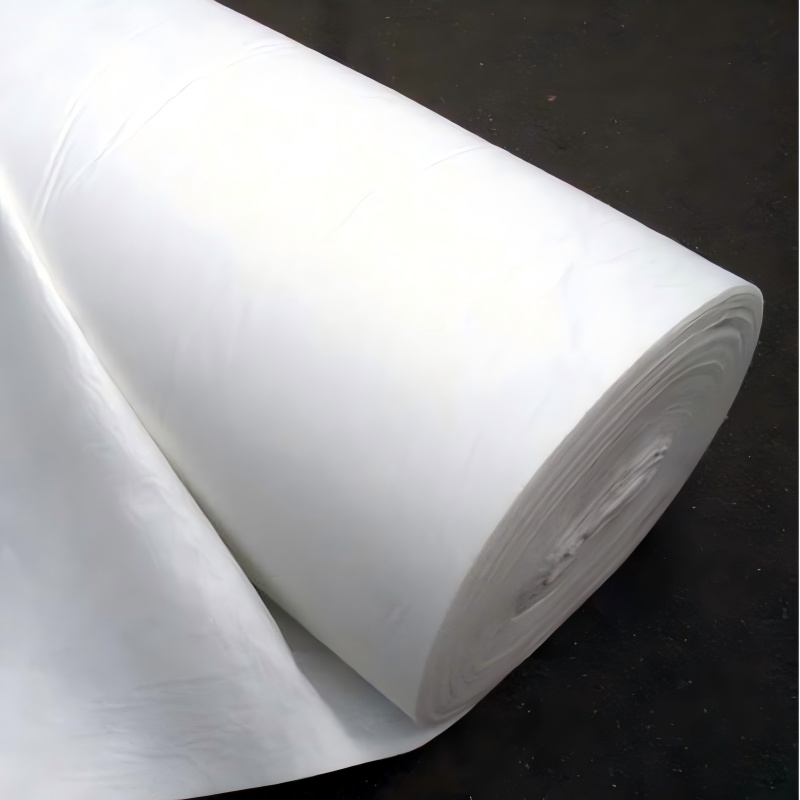

Needle Punched Geotextile

Excellent Permeability & Filtration

Its three-dimensional porous structure allows water to pass through freely while effectively intercepting and retaining soil particles, preventing piping and soil loss, thereby ensuring long-term, stable filtration.Effective Separation

When installed between different soil layers or materials, it prevents their intermixing, maintaining the structural function and overall load-bearing capacity of each layer. It is particularly suitable for soft soil foundation treatment.Reinforcement & Protection

Through fiber friction and tensile strength, it can distribute localized stresses, restrict lateral soil displacement, and enhance surface stability and resistance to shallow erosion.Durability & Resistance

Synthetic fibers are chemically stable, offering resistance to acids, alkalis, microorganisms, and insect infestation. They provide a long service life when properly installed and buried.Ease of Installation & Cost-Effectiveness

The material is soft, lightweight, and can be easily cut and seamed to conform to complex terrain. Mechanized installation is efficient, resulting in lower overall project costs.

Product Introduction:

Needle-punched non-woven geotextile is a fabric-like material manufactured through a mechanical needle-punching process, where barbed needles entangle and consolidate a fiber web. It is primarily made from polyester (PET) or polypropylene (PP) staple fibers. This product features a three-dimensional fiber network structure, presenting a fluffy, felt-like appearance, and offers excellent permeability and soil compatibility.

Product Parameters:

project | metric | ||||||||||

| Nominal strength/(kN/m) | |||||||||||

| 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

| 1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

| 2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

| 3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

| 4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

| 5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

| 7 | Width deviation rate /% ≥ | -0.5 | |||||||||

| 8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

| 9 | Thickness deviation rate /% ≥ | -10 | |||||||||

| 10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

| 11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

| 12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

| 13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

| 14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

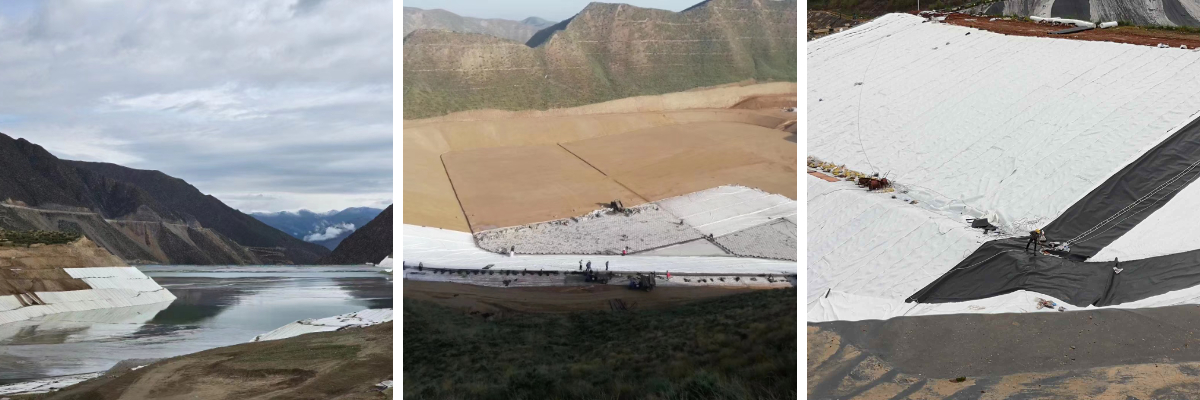

Product Applications:

Road & Railway Construction

Used as a separation layer in roadbeds and railway subgrades to prevent mixing between the base aggregate and subsoil, reducing frost heave and mud pumping, thereby extending pavement life.Hydraulic & Marine Engineering

Serves as a filter layer and protection cushion in dams, reservoirs, riverbanks, and coastal revetments to prevent soil erosion. Also used to wrap subsurface drains, replacing traditional granular filters.Environmental & Landfill Projects

Acts as a protective layer within landfill liner systems, a filter material for leachate collection layers, and a drainage layer in final cover systems.Erosion Control

Applied on slopes, channels, and shorelines for scour protection. When combined with vegetation, it provides temporary soil stabilization and facilitates revegetation.Subsurface Drainage Systems

Used to wrap drainage pipes or form French drains, preventing siltation and ensuring long-term drainage performance.Large-Scale Platforms (Airports, Ports)

Provides preliminary reinforcement for soft ground, separates fill materials, and improves overall platform stability.

Conclusion

With its unique fibrous structure, needle-punched non-woven geotextile excels in filtration, separation, drainage, and protection. It has become an essential material in modern civil engineering, hydraulic projects, and environmental construction. Its cost-effectiveness and ease of installation further promote its widespread use across various infrastructure projects.