Geomembrana 60 mils

1. Outstanding Anti-seepage Performance:It can effectively block liquid penetration. Whether it is water resources or pollutants, a tight barrier can be formed through it, reducing the risk of leakage and ensuring the anti-seepage effect of the project.

2. Strong Adaptability:It has certain flexibility and mechanical strength, can adapt to the laying of base surfaces with different terrains, and is resistant to acids, alkalis and aging, so it can maintain stable performance in various complex environments.

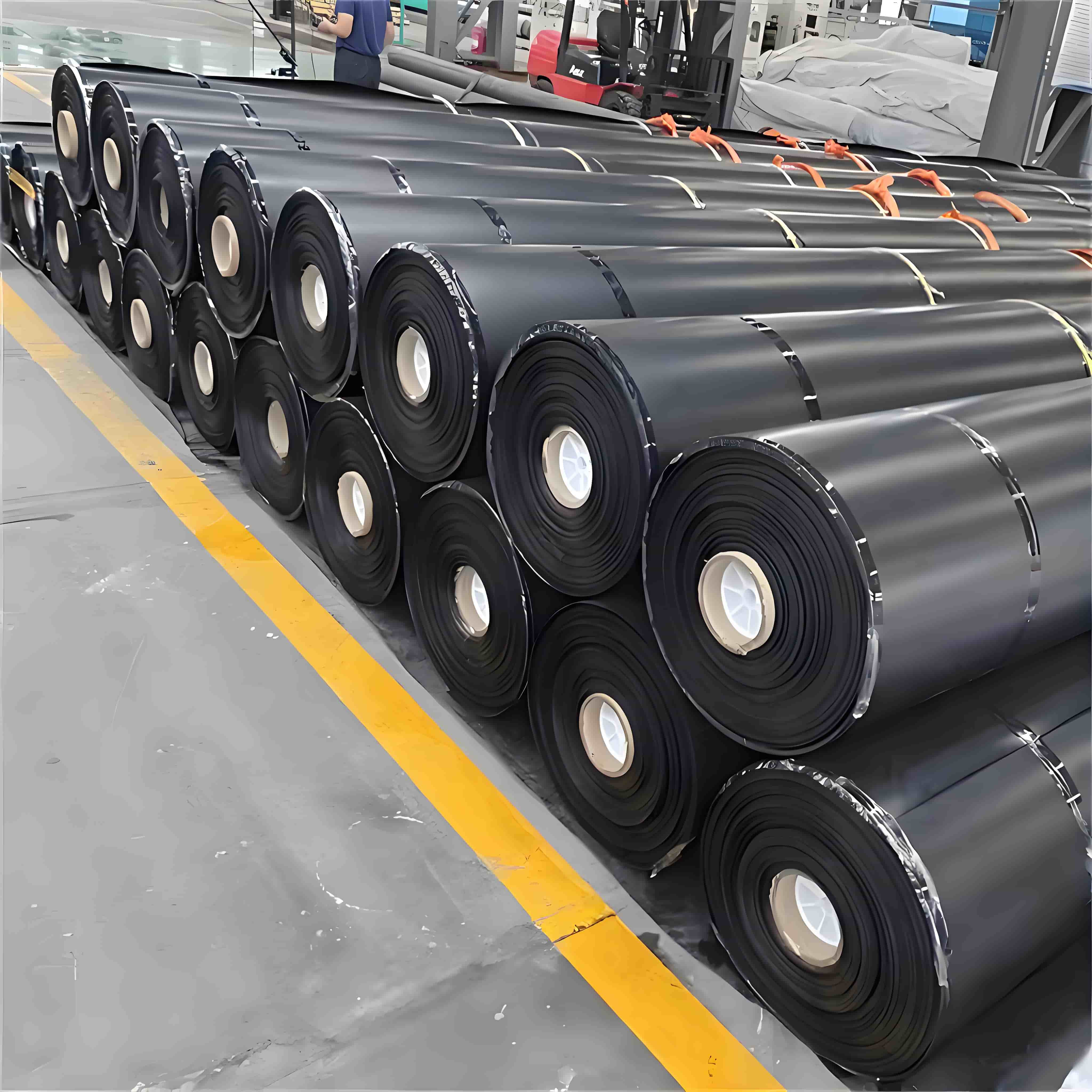

3. Convenient and Efficient Construction:The laying process is relatively simple and can be completed quickly through lapping or welding, which can shorten the project duration. At the same time, the maintenance cost is low, which helps to improve the overall efficiency of the project.

4. Wide Application Value:It can play a role in many fields such as water conservancy, environmental protection, transportation, and agriculture. It not only saves resources but also protects the ecological environment, providing reliable guarantees for various projects.

Product Introduction

1、 Basic Definition

Made of high molecular weight polymers such as polyethylene and ethylene vinyl acetate copolymer, it is a waterproof barrier material with anti-seepage and isolation functions. It also has certain tensile strength and tear resistance, and can adapt to various engineering scenarios.

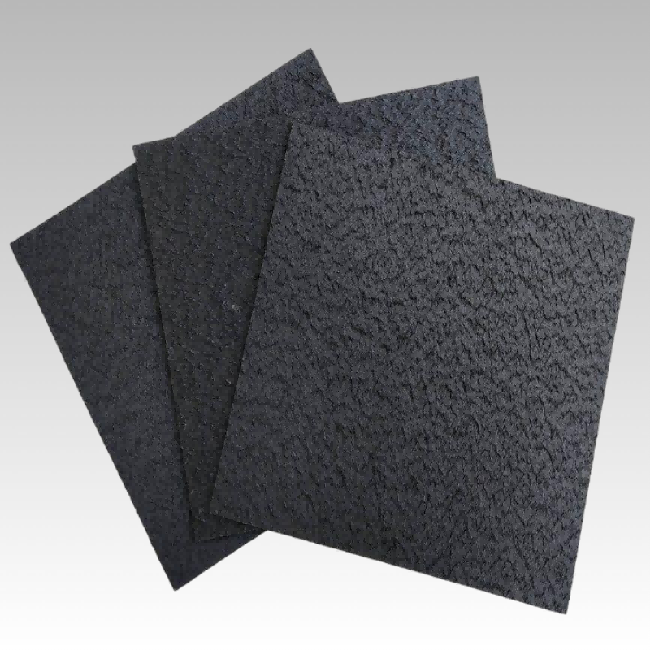

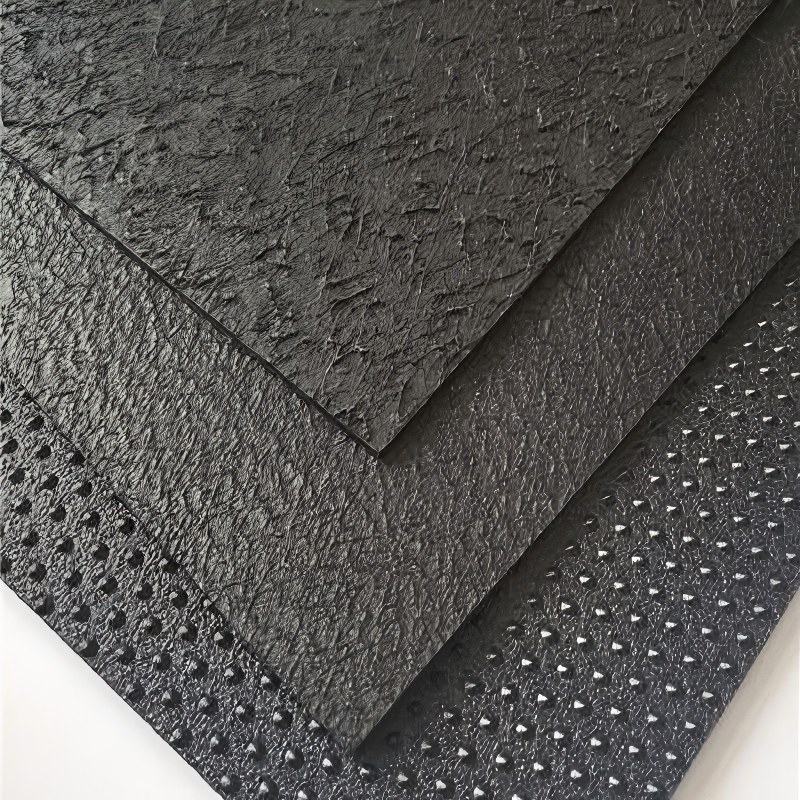

2、 Common types

Including HDPE geomembrane, LDPE/EVA geomembrane, and composite geomembrane, they have outstanding performance in corrosion resistance, flexibility, and comprehensive performance, respectively.

3、 Main features

Good anti-seepage effect, can prevent liquid infiltration and pollutant diffusion; Strong adaptability, easy construction, and low maintenance costs.

4、 Application scope

Widely used, it plays an important role in water conservancy, environmental protection, transportation, agriculture and other fields, and is an important material for multi field engineering construction.

Product Parameters

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

Product Application

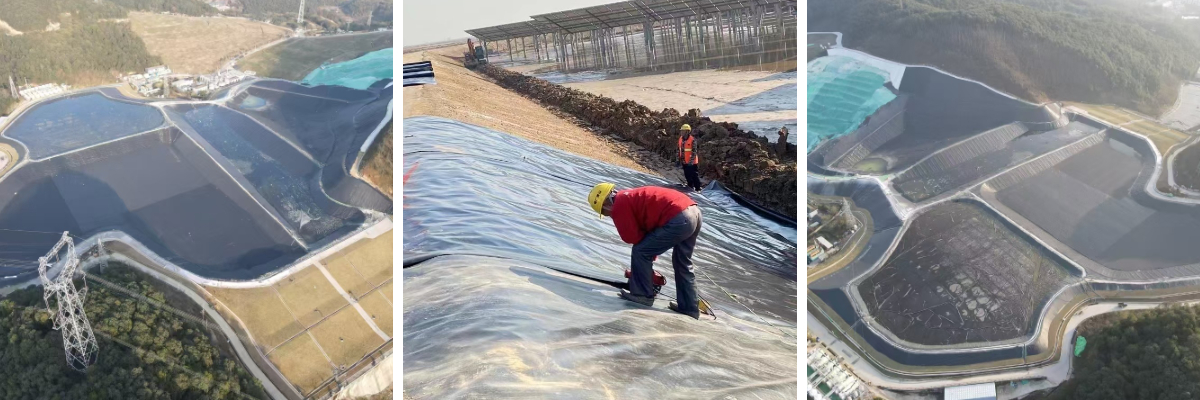

(1) Water conservancy engineering

Reservoir and channel anti-seepage: prevent water leakage and improve water resource utilization efficiency.

Embankment and cofferdam anti-seepage: reduce seepage and enhance structural stability.

Artificial lakes and landscape water pools: prevent water loss and maintain landscape effects.

Fish ponds and shrimp ponds: reduce leakage and improve aquaculture efficiency.

(2) Environmental Protection Engineering

Landfill site: serves as a bottom liner and cover layer to prevent leachate from contaminating soil and groundwater.

Sewage treatment tank: prevent sewage leakage and protect the surrounding environment.

Hazardous waste storage site: isolate harmful substances to prevent environmental pollution.

Tailings pond anti-seepage: prevent heavy metals and chemicals from infiltrating underground.

(3) Municipal and Construction Engineering

Underground engineering waterproofing: such as anti-seepage engineering for basements, tunnels, subways, etc.

Roof greening and anti-seepage: prevent moisture from seeping into the building structure.

Artificial wetlands: control water infiltration and improve sewage treatment efficiency.

(4) Agricultural applications

Agricultural reservoir: Reduce irrigation water leakage.

Biogas pool anti-seepage: Improve the efficiency of biogas collection and prevent leakage.

Salt field anti-seepage: improving the production efficiency of salt industry.

(5) Mining and Energy Engineering

Heap leaching tank anti-seepage: used for solution anti-seepage during metal extraction processes such as gold and copper mines.

Petrochemical anti-seepage: used for anti-seepage protection in oil tank areas and chemical plants.

Coal ash yard: prevent coal ash from polluting groundwater.

Geomembranes have played an irreplaceable role in key fields such as water conservancy, environmental protection, transportation, and agriculture due to their excellent anti-seepage and isolation performance. It not only ensures the stable operation of various projects, but also makes significant contributions to water resource protection, ecological environment maintenance, and other aspects. It is an important material for improving efficiency and safety in modern engineering construction.