Geotextile Cloth Bunnings

1. High strength and durability

Strong tensile and tear resistance, able to withstand mechanical stress during construction and long-term use.

Corrosion resistance, UV resistance, and long service life.

2. Permeability and Filtration

Allow water to pass through while preventing soil particle loss, preventing clogging, and maintaining structural stability.

3. Lightweight and easy to construct

Lightweight, easy to transport and lay, reducing construction time and costs.

4. Environmental friendliness

Some materials can be recycled to reduce environmental damage

Product Introduction:

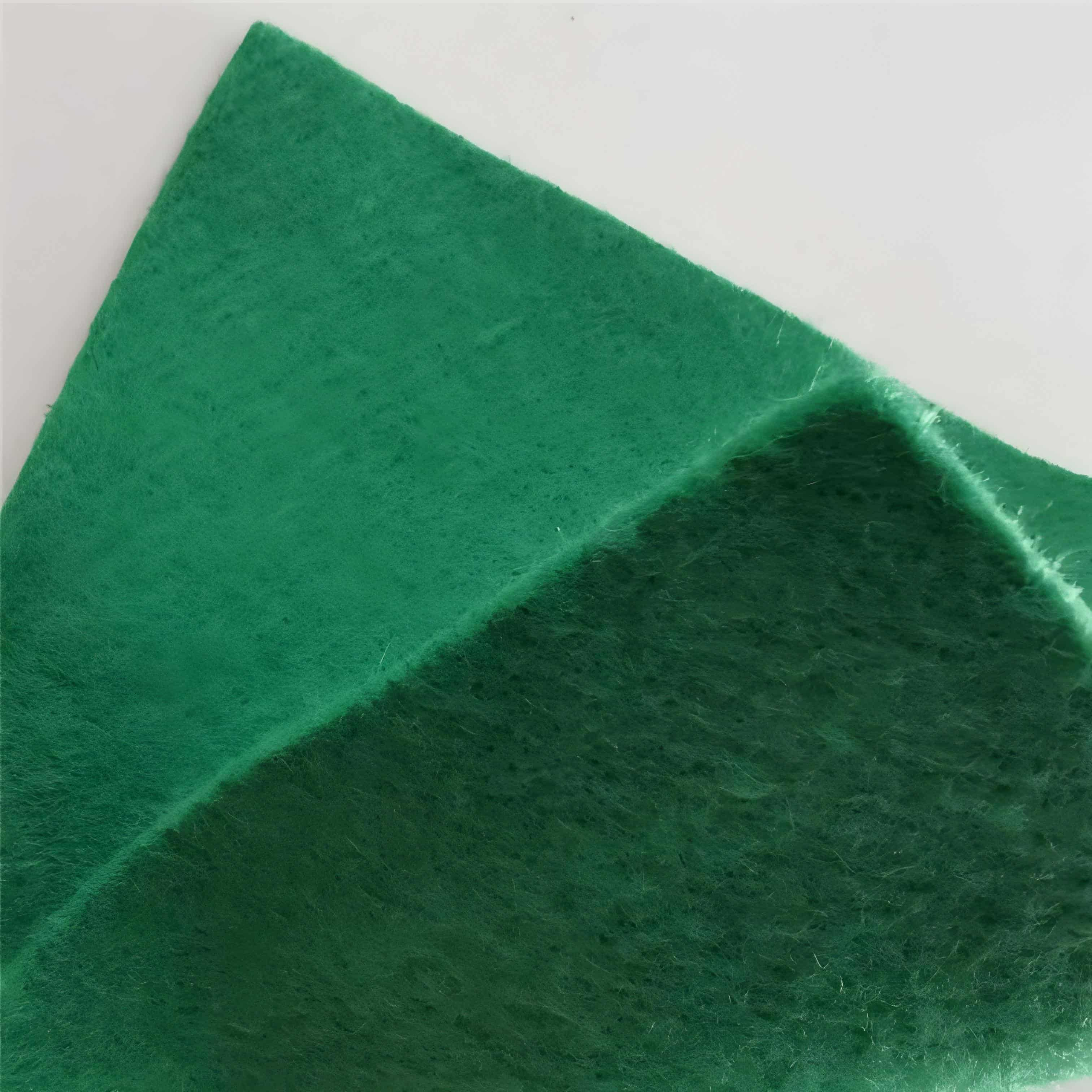

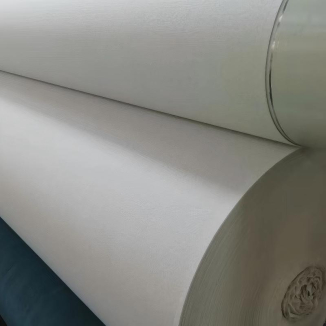

Geotextile Cloth Bunnings are a permeable geosynthetic material made of synthetic fibers through needle punching or weaving. Its raw materials are mostly high molecular weight polymers such as polypropylene, polyester, nylon, etc., which are processed through different processes to form fabric structures with certain thickness, porosity, and mechanical properties, which can adapt to various environmental and load conditions in civil engineering.

characteristic

1. Filtration: When water flows through geotextiles, their pores can block impurities such as soil particles, prevent soil erosion, and ensure normal water infiltration. For example, in the construction of dams in hydraulic engineering, geotextiles can filter the water flow on both sides of the dam to prevent soil erosion.

2. Drainage: The pores inside the geotextile form drainage channels, which can quickly drain the accumulated water inside the structure, reduce pore water pressure, and improve the stability of the structure. In highway construction, geotextile can be laid in the roadbed to drain accumulated water and prevent roadbed settlement.

3. Isolation: It can separate materials of different properties, prevent them from mixing with each other, and ensure that each material can exert its own performance. In railway construction, geotextile can isolate the crushed stones under the railway tracks from the roadbed soil, preventing crushed stones from entering the roadbed soil and affecting the stability of the railway tracks.

4. Reinforcement: Through its own high strength, it can enhance the bearing capacity and deformation resistance of the soil, and improve the mechanical properties of the soil. In the treatment of soft soil foundation, geotextile can be used as a reinforcement material to improve the bearing capacity of the foundation and reduce its settlement.

5. Protection: It can protect soil or other structures from erosion and damage caused by external factors. For example, in river regulation projects, geotextiles can be laid on river slopes to prevent water flow from scouring the slopes.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

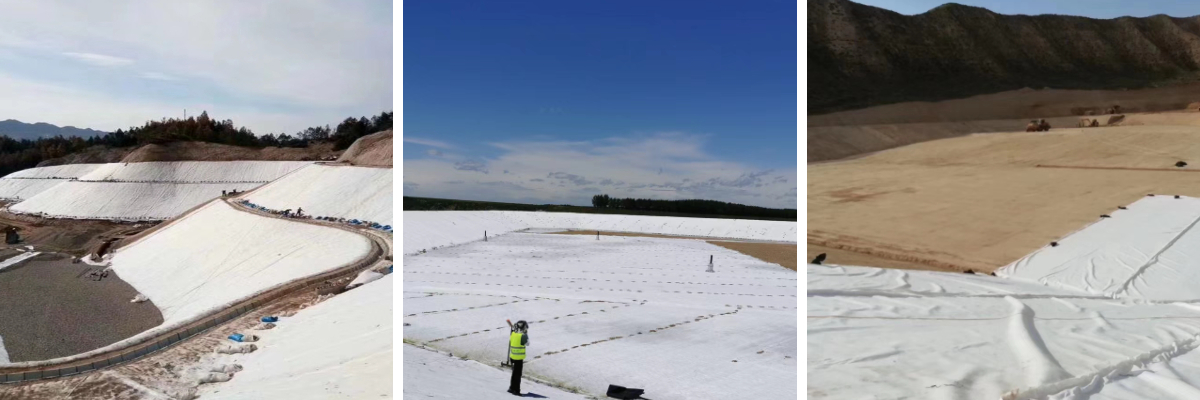

1. Water conservancy engineering

The anti erosion materials for dams and slope protection prevent water flow from emptying the foundation through reverse filtration.

The drainage filter layer of reservoirs and wells accelerates the discharge of seepage and reduces water pressure.

2. Transportation Engineering

Reinforcement materials for highway and railway roadbeds enhance the bearing capacity of weak foundations and reduce settlement.

The drainage base of airport runways and sports fields can quickly drain rainwater and prevent water accumulation.

3. Environmental Protection Engineering

The component of the anti-seepage system at the bottom of the landfill site, combined with geomembrane to prevent leachate pollution.

The filter layer of tailings dam and ash storage dam controls the migration of solid particles in seepage.

4. Construction and Municipal Engineering

The outer waterproof material of the basement and tunnel is combined with concrete to form an anti-seepage barrier.

The substrate material for artificial lakes and landscape water pools replaces traditional clay anti-seepage layers.

5. Agricultural Engineering

The filter layer of the farmland drainage system prevents soil particles from blocking the drainage pipes.

The isolation layer in the improvement of saline alkali land prevents the rise of salt and protects crop roots.

6. Mining Engineering

The drainage material for mining beneficiation accelerates tailings dewatering and improves processing efficiency.

Reinforcement materials for rockfill dams and tailings dams enhance the stability of the dam body.

7. Coastal and Ocean Engineering

Anti erosion materials for breakwaters and revetments to resist wave erosion.

The protective layer of artificial reefs and underwater pipelines reduces biological attachment and mechanical damage.

8. Temporary works

The reinforcement materials for construction access roads and temporary cofferdams can be quickly built and recycled.

Emergency materials for disaster response, such as dam repair after floods and road reinforcement after earthquakes.

Geotextile has become an indispensable basic material in fields such as water conservancy, transportation, and environmental protection due to its core advantages of high strength, permeability, corrosion resistance, as well as convenient construction and environmental safety. From dam protection to urban drainage, from mine restoration to agricultural improvement, geotextiles silently guard the quality of engineering as "invisible guardians" and promote the achievement of green building and sustainable development goals. With the continuous advancement of material technology, the application scenarios of geotextiles will continue to expand, providing more efficient and economical solutions for modern engineering construction.