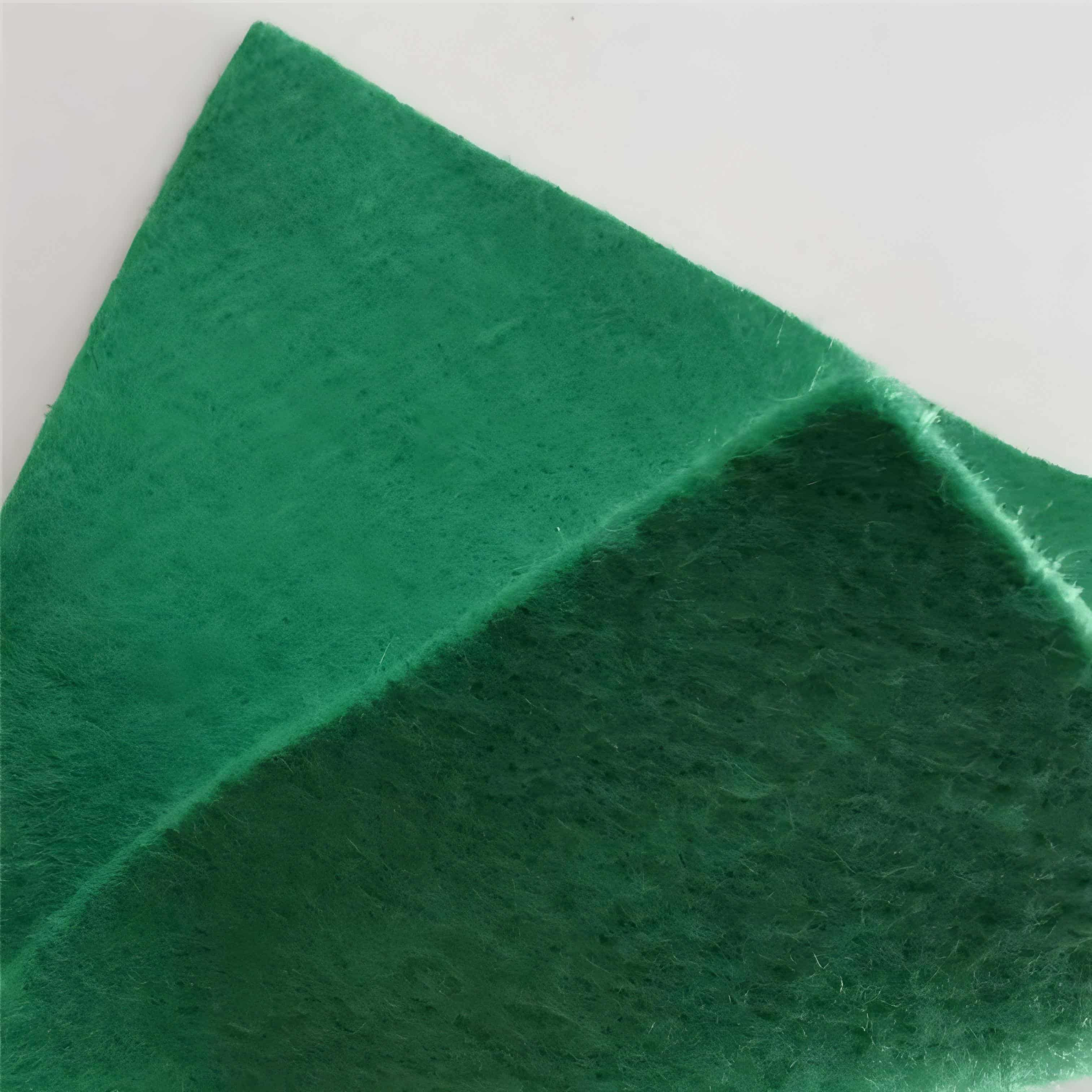

Non Woven Geotech Fabric

1.Efficient drainage:The porous structure enables fast drainage speed, lowers groundwater level, and reduces soil pressure.

2.Good filtering performance:It can intercept soil particles to prevent loss, while ensuring water and air flow, and maintaining structural stability.

3.Effortless construction:Light texture, good flexibility, easy cutting and laying, conducive to shortening the construction period.

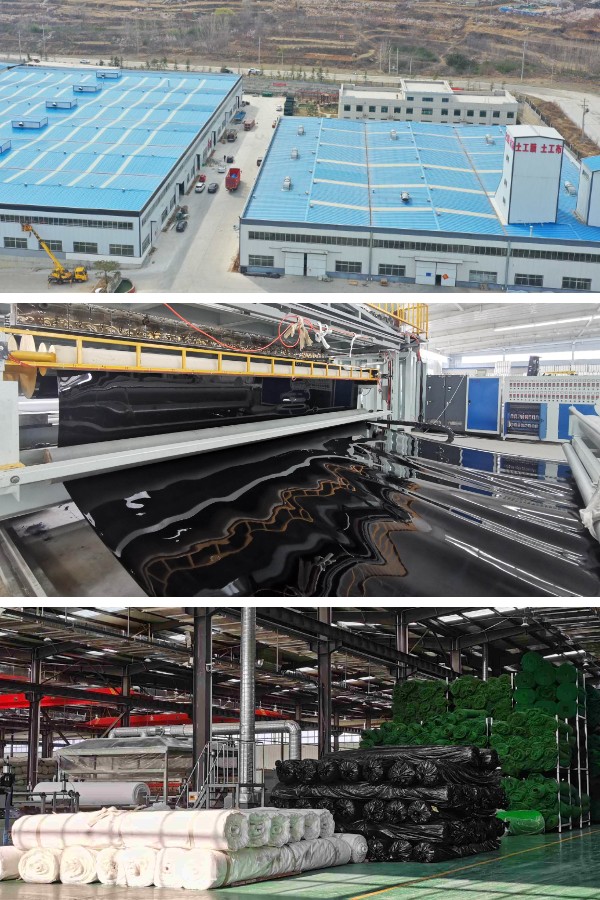

4.High cost-effectiveness:The production process is simple, the raw materials are wide, the cost is low and durable, which can reduce the total project cost.

5.Strong adaptability:Acid and alkali resistance, corrosion resistance, stable performance in various environments, and wide application fields.

Product Introduction

Basic attributes

Non Woven Geotech Fabric are mainly made of high molecular weight polymer fibers such as polyester and polypropylene, and processed through non-woven processes such as needle punching, hot melt, and spunbond. Its finished product has a lightweight texture, with a unit area mass usually between 100-600g/m ², outstanding flexibility, and can be bent and folded freely without being easily damaged. The unique porous structure makes its porosity generally reach over 70%, and the pore distribution is uniform, which can ensure smooth water flow and intercept small soil particles. The raw materials are widely sourced, and in addition to common synthetic fibers, some products also use recycled fibers. The production process does not require traditional spinning and weaving steps, and the process flow is relatively simple, enabling continuous large-scale production.

Core functions

Drainage: Relying on a dense and interconnected porous structure, it can quickly divert pore water, surface water, and groundwater in the soil, with a drainage rate of 10-100m ³/(m ² · d). It can effectively lower the groundwater level, reduce soil pore water pressure, and avoid settlement, deformation, or leakage of engineering structures due to long-term water accumulation.

Filtering: By forming a three-dimensional network structure between fibers, gradient interception of soil particles in water flow is carried out to prevent the loss of fine soil particles with water, while ensuring smooth passage of water and air, maintaining the permeability stability of soil. In scenarios such as dams, channels, and roadbeds in water conservancy engineering, it can effectively prevent disasters such as piping and soil flow.

Main features

Convenient construction: Due to its lightweight texture, the weight of a single roll is usually between 50-200kg, and it can be easily transported manually or mechanically; Good flexibility, able to adapt to the undulating changes of different terrains, no special tools are required for cutting, and the laying process can be quickly spliced, greatly reducing the construction process. Compared with traditional geotechnical materials, it can shorten the construction period by more than 30%.

High cost-effectiveness: The raw material cost is relatively low, and the production process has a high degree of automation. The manufacturing cost per unit product is only 60% -80% of that of woven geotextiles; At the same time, the product has good aging resistance and wear resistance, with a service life of over 50 years in natural environments, and low maintenance costs in the later stage, which can significantly reduce the overall project cost.

Strong adaptability: It has excellent acid and alkali resistance, stable performance in environments with pH values of 3-11, and strong resistance to corrosive media such as saline soil and industrial wastewater; It has outstanding resistance to microbial erosion and is not easily decomposed by bacteria and fungi in the soil. It can play a long-term role in complex environments such as wetlands and mining areas, and is widely used in various fields such as highways, railways, water conservancy, environmental protection, municipal engineering, and mining.

Product Parameters

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

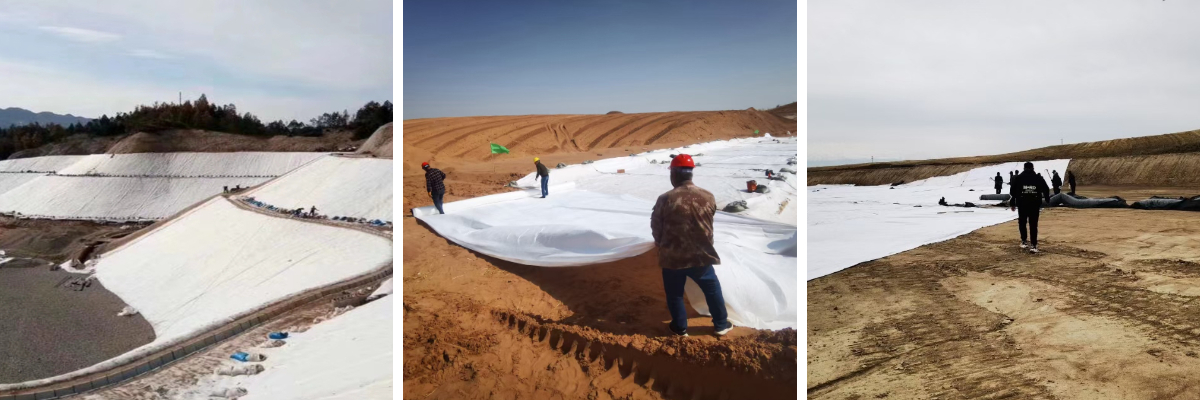

Product Application

Highway engineering

In highway construction, non-woven geotextiles are often laid between the roadbed and the base layer. It can play a role in filtering and drainage, effectively preventing soil particles from entering the base layer, avoiding damage to the base structure, and quickly draining accumulated water in the roadbed, reducing roadbed settlement, and improving the stability and service life of the highway. In addition, in highway widening projects, its flexibility and tensile strength can be utilized to alleviate uneven settlement at the junction of new and old roadbeds.

Water conservancy engineering

Non woven geotextiles are widely used in dams, channels, and other parts of hydraulic engineering. In dam construction, it can serve as an anti filter layer to prevent the soil of the dam from being washed away by water flow, while ensuring the smooth discharge of seepage from the dam and ensuring the safety and stability of the dam. For channels, laying non-woven geotextiles can reduce the erosion of water flow on channel slopes, play a role in anti-seepage and protection, and extend the service life of channels.

Railway Engineering

The railway subgrade requires extremely high stability, and non-woven geotextiles play an important role in this regard. It can filter the moisture in the roadbed, prevent the loss of fine soil particles, and maintain the bearing capacity of the roadbed. At the same time, its good drainage performance can reduce the moisture content of the roadbed, avoid problems such as frost heave and frost heave, ensure the smoothness of the railway track, and guarantee the safe operation of trains.

Environmental Protection Engineering

In environmental engineering, non-woven geotextiles are often used in landfills. It can serve as a protective layer for anti-seepage liners, preventing the anti-seepage membrane from being punctured by sharp objects, while also playing a filtering and drainage role, collecting and discharging leachate from garbage, and avoiding soil and groundwater pollution caused by leachate. In addition, its filtration performance can also be utilized in river dredging, ecological restoration and other projects to purify water quality and improve the ecological environment.

Municipal Engineering

Non woven geotextiles will be used in the construction of roads, parking lots, and green belts in municipal engineering. In road base treatment, it can enhance the overall integrity of the base and reduce the occurrence of pavement cracks; In the construction of parking lots, the bearing capacity of the foundation can be improved to prevent ground settlement; In green belts, it can play a role in water retention and filtration, which is beneficial for plant growth.

Non Woven Geotech Fabric have indispensable applications in many engineering fields such as highways, water conservancy, railways, environmental protection, and municipal engineering due to their excellent filtration, drainage, and reinforcement properties. It can not only improve the quality and stability of engineering, extend the service life of engineering, but also reduce the maintenance cost of engineering, providing strong guarantee for the smooth and long-term operation of various projects. It is a highly practical engineering material.