Geotextile Tube Bags

1.Cost-Effective:

Saves 30%-50% in costs compared to traditional concrete or stone structures.

2.Easy Construction:

Can be filled on-site, adapts to complex terrains, and requires no heavy machinery.

3.Eco-Friendly:

Reduces excavation and transportation pollution, with fill materials available locally.

4.Durability:

Resistant to chemical corrosion, with a service life of over 10 years (depending on environmental conditions).

Product Introduction:

Geotextile Tube Bags are a large tubular container fabricated from high-strength geotextile materials. It is designed to be filled with slurry substances such as sediment, sludge, or industrial waste. By leveraging the fabric’s filtration and breathability properties, it achieves solid-liquid separation, ultimately forming a stable solid structure. Geotextile tubes are widely used in environmental protection, water conservancy, and coastal engineering projects.

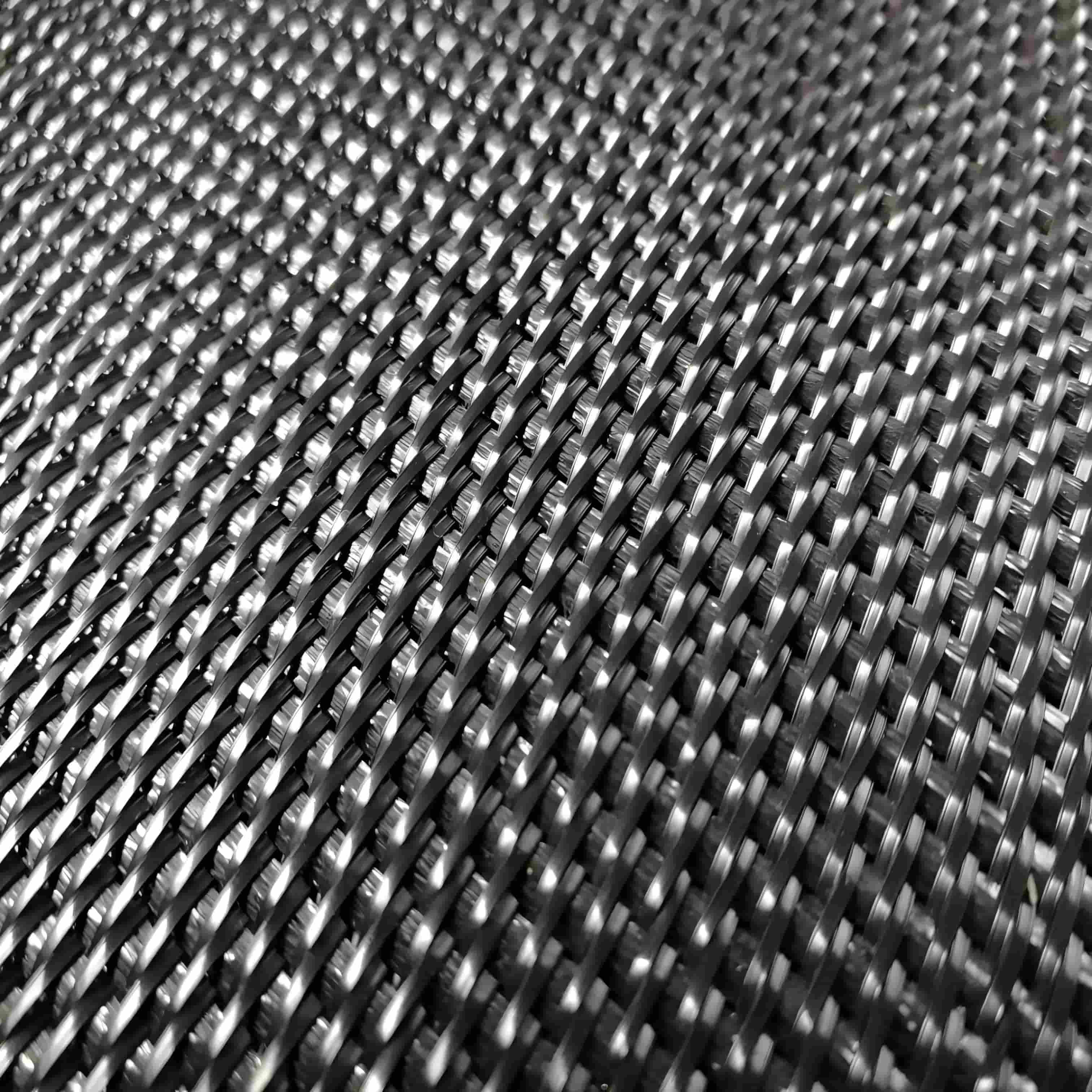

Material Characteristics:

1.Fabric Type: Typically made of polypropylene (PP) or polyester (PET), available in woven or non-woven geotextile forms, featuring UV resistance, corrosion resistance, and high tensile strength.

2.Permeability: Allows water to drain while retaining solid particles, accelerating dewatering and solidification.

3.Pore Size Control: The fabric’s permeability is selected based on the particle size of the fill material to prevent fine-particle loss.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1.Hydraulic Engineering

Commonly used for constructing the core of revetments, breakwaters, wave-dissipating dams, as well as river regulation and cofferdam projects. It can use local materials such as sand and soil to fill geotextile tubes, forming a stable dam structure that effectively resists the erosion of water flow and ocean waves.

2.Environmental Governance

Widely applied in dredging projects of rivers, lakes, reservoirs and other water bodies. Polluted sludge can be filled into geotextile tubes for dewatering, reducing the volume of sludge and lowering environmental pollution. Meanwhile, the treated sludge can be used as greening soil or for wetland restoration.

3.Marine Engineering

Such as reclamation from the sea, construction of artificial islands, and submarine pipeline protection. Geotextile tubes can serve as the main structure of embankments. By filling materials like sea sand, they form a closed embankment area, creating conditions for subsequent engineering construction.

4.Sewage Treatment

Used for sludge dewatering in sewage treatment plants, which can improve the dewatering efficiency of sludge, reduce its volume, and lower the difficulty and cost of sludge treatment and disposal.