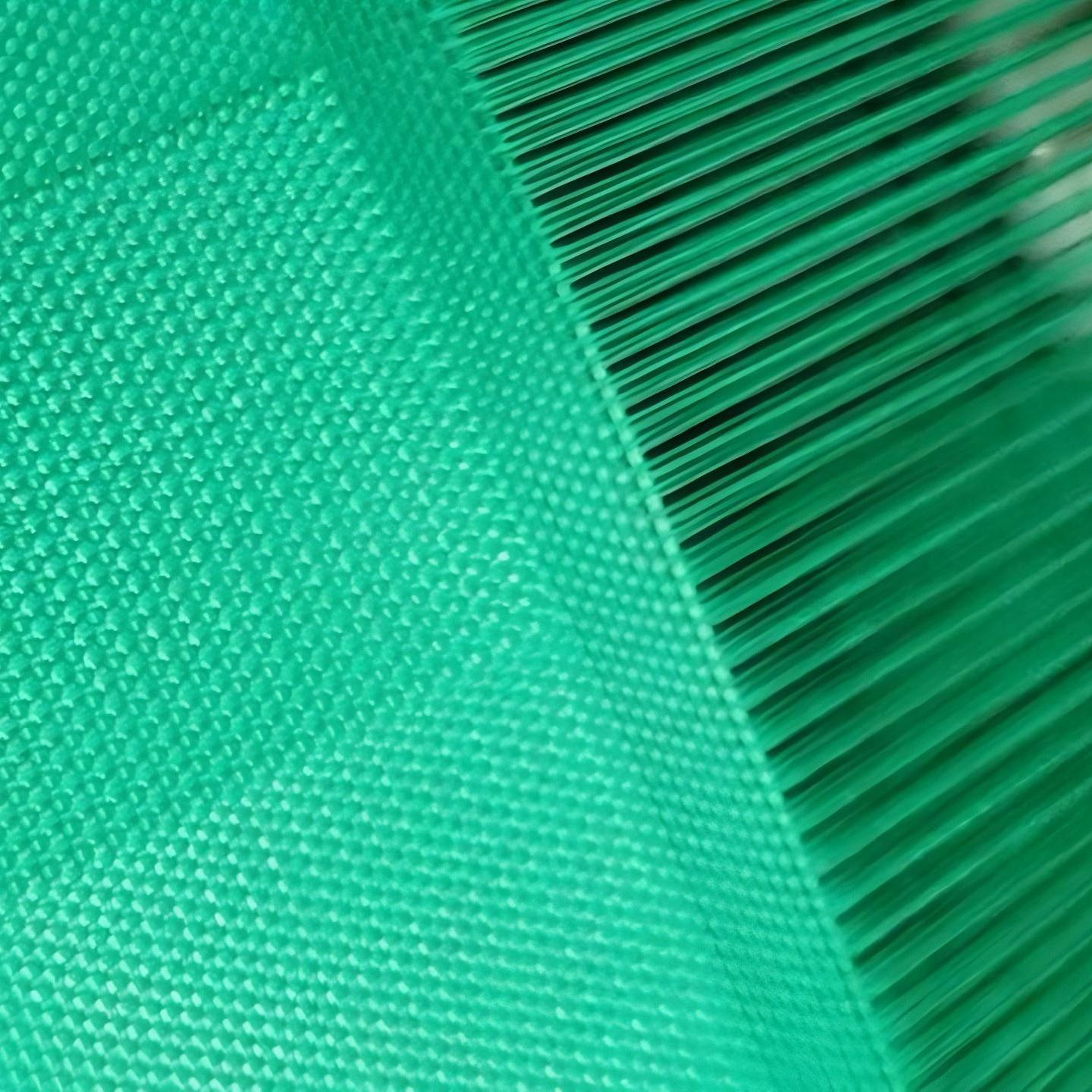

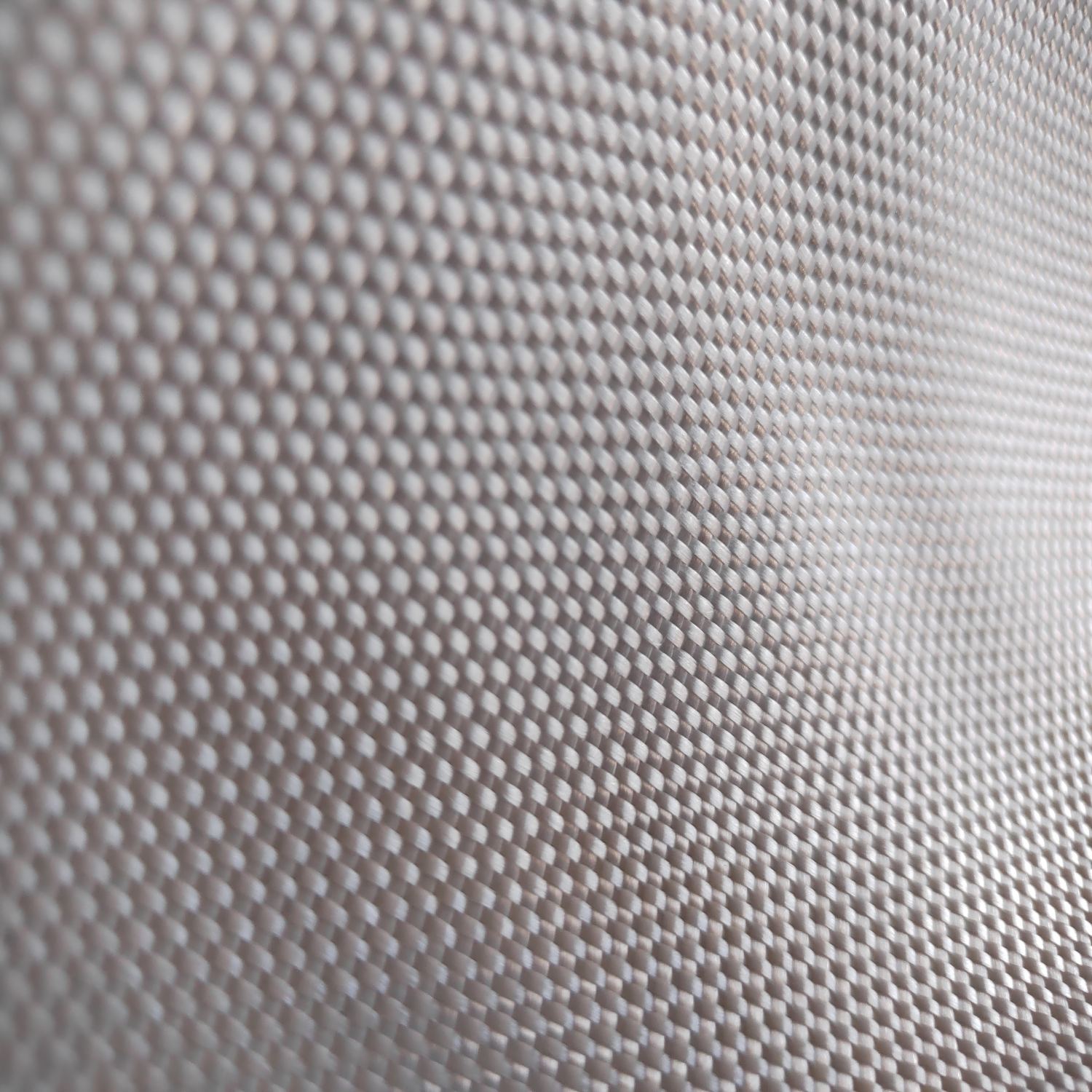

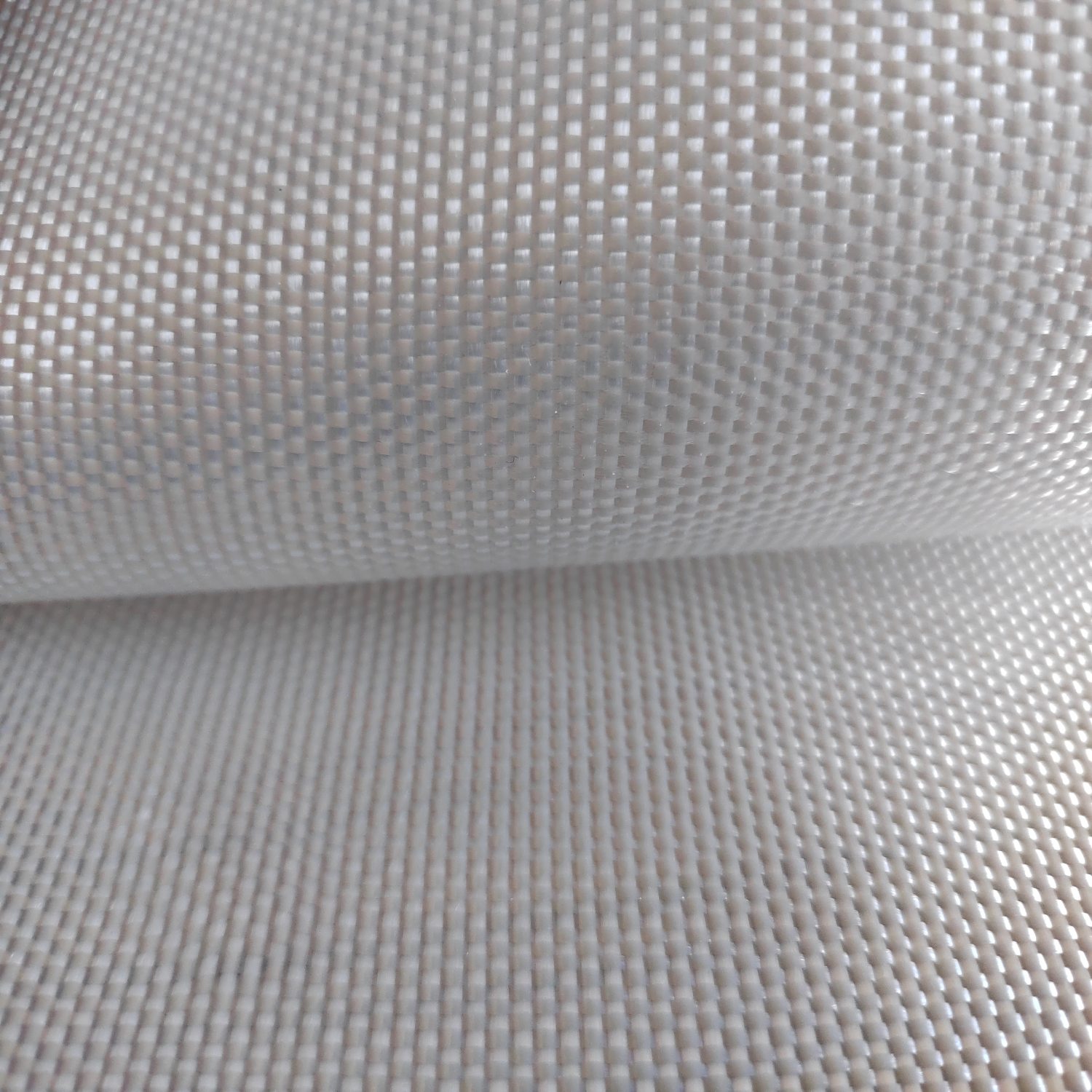

Woven Polypropylene Geotextile

1.Excellent corrosion resistance: Resistant to acids and alkalis, anti-aging, and not easy to deteriorate when used outdoors.

2.Good water permeability: It can drain water and intercept sand, forming an internal drainage channel.

3.High strength: Strong tensile strength in both longitudinal and transverse directions, which can enhance the stability of soil.

4.Convenient construction: Lightweight, easy to carry and lay, improving construction efficiency.

5.Environmentally friendly and recyclable: The raw materials are non-toxic, and it can be recycled and reused after being discarded.

Product Introduction:

Woven Polypropylene Geotextile is a type of geotextile made mainly from polypropylene. It consists of at least two sets of parallel yarns (or flat filaments). One set along the longitudinal direction of the loom is called the warp yarn, and the other set arranged transversely is called the weft yarn. It is manufactured through special machine weaving techniques.

Characteristic

Superior mechanical properties: It has quite strong tensile strength both longitudinally and transversely. Generally, the tensile strength in the longitudinal direction is greater than that in the transverse direction. It can withstand large tensile forces, tearing forces, and abrasion. It can effectively enhance the tensile strength and deformation resistance of the soil, and improve the stability of the building structure.

Good permeability: The woven structure endows the geotextile with good water permeability. Under the pressure of soil and water, it can still maintain good water permeability, allowing water to pass through. At the same time, it can effectively intercept sand and prevent its loss. It can form a drainage channel inside the soil mass, discharging the excess liquid and gas within the soil structure.

High corrosion resistance: Made from chemical fibers such as polypropylene, it has the characteristics of acid and alkali resistance, non - corrosion, non - moth - eating, and oxidation resistance. It can maintain stable performance in harsh chemical environments and has a long service life.

Strong corrosion resistance: Made from chemical fibers such as polypropylene, it has the characteristics of acid and alkali resistance, non-corrosion, non-moth-eaten, and oxidation resistance. It can maintain stable performance in harsh chemical environments and has a long service life.

Good UV resistance and weather resistance: After special treatment, it has good UV resistance. When exposed to outdoor environments for a long time, it is not easy to age or fade, and can maintain the stability of its physical properties. It is suitable for various outdoor engineering environments.

Environmental Protection and Recyclability: The polypropylene material is non-toxic and recyclable. Discarded woven polypropylene geotextiles can be recycled through appropriate recycling channels, meeting environmental protection requirements.

Easy to construct: It is relatively light in weight, which is convenient for handling and construction. During the construction process, it can be easily deployed and fixed, which can improve the construction efficiency.

Product Parameters:

| project | metric | |||||||||||||

| Nominal strength/(kN/m) | ||||||||||||||

| 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | ||||

| 1 Tensile strength per (kN/m) ≥ | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 250 | |||

| 2. Weft tensile strength / (kN/m) ≥ | After tensile strength is multiplied by 0.7 | |||||||||||||

| 3 | Maximum elongation at maximum load/% | warp direction ≤ | 35 | |||||||||||

| broadwise ≤ | 30 | |||||||||||||

| 4 | Top penetration force /kN is greater than or equal to | 2 | 4 | 6 | 8 | 10.5 | 13 | 15.5 | 18 | 20.5 | 23 | 28 | ||

| 5 | Equivalent aperture O90 (O95)/mm | 0.05~0.50 | ||||||||||||

| 6 | Vertical permeability coefficient/(cm/s) | K× (10⁵~102) where: K=1.0~9.9 | ||||||||||||

| 7 | Width deviation rate /% ≥ | -1 | ||||||||||||

| 8 | Tear strength in both directions /kN ≥ | 0.4 | 0.7 | 1 | 1.2 | 1.4 | 1.6 | 1.8 | 1.9 | 2.1 | 2.3 | 2.7 | ||

| 9 | Unit area mass deviation rate /% ≥ | -5 | ||||||||||||

| 10 | Length and width deviation rate/% | ±2 | ||||||||||||

| 11 | Joint/seam strength a/(kN/m) ≥ | Nominal strength x 0.5 | ||||||||||||

| 12 | Anti-acid and alkali properties (strong retention of warp and weft Rate) a /% ≥ | Polypropylene: 90; other fibers: 80 | ||||||||||||

| 13 | Ultraviolet resistance (Xenon arc lamp method) b | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

| 14 | Ultraviolet resistance (fluorescencePhotometric ultraviolet lamp method) | The strength retention rate in both directions is /%≥ | 90 | |||||||||||

Product Applications:

Environmental Protection Engineering

Landfill: Prevent seepage, isolate garbage from soil, and prevent sewage leakage from polluting the environment.

Sewage Treatment: Assist in solid-liquid separation, intercept impurities and drain water, improving treatment efficiency.

Mining Engineering

Tailings / Waste Residue Treatment: Strengthen the stockpile to prevent the loss of slag and reduce the risk of environmental pollution.

Hydraulic Engineering

Dike/River Channel Protection: Prevent scouring and seepage, block the loss of sand and soil, and maintain the stability of the embankment.

Coastal Engineering: Resist wave erosion, act as a filter layer to guide water flow, and protect the coastal structure.

Traffic Engineering

Highway / Railway Subgrade: Reinforce the subgrade, disperse soil stress, and prevent settlement and slippage.

Slope Protection: Inhibit soil erosion, avoid slope collapse, and ensure road safety.

Agriculture and Soil and Water Conservation

Irrigated Agriculture: Canal Seepage Control, Farmland Drainage, and Improvement of Water Resource Utilization Efficiency.

Soil and Water Conservation: Preventing Soil Erosion of Cultivated Land, or Using as Horticultural Ground Cover to Suppress Weeds and Conserve Soil Moisture

Other Scenarios

Foundation Reinforcement in Civil Engineering: Enhance the bearing capacity of soft soil foundations and reduce the potential for deformation.

Anti-seepage for Artificial Lakes/Reservoirs: Combine with other materials to form an anti-seepage system and reduce water leakage.

Through functions such as "reinforcement, filtration, drainage, anti-seepage, and isolation", the stability of engineering structures is enhanced, soil erosion and environmental pollution are reduced, and it is applicable to various civil, environmental protection, and water conservancy projects.