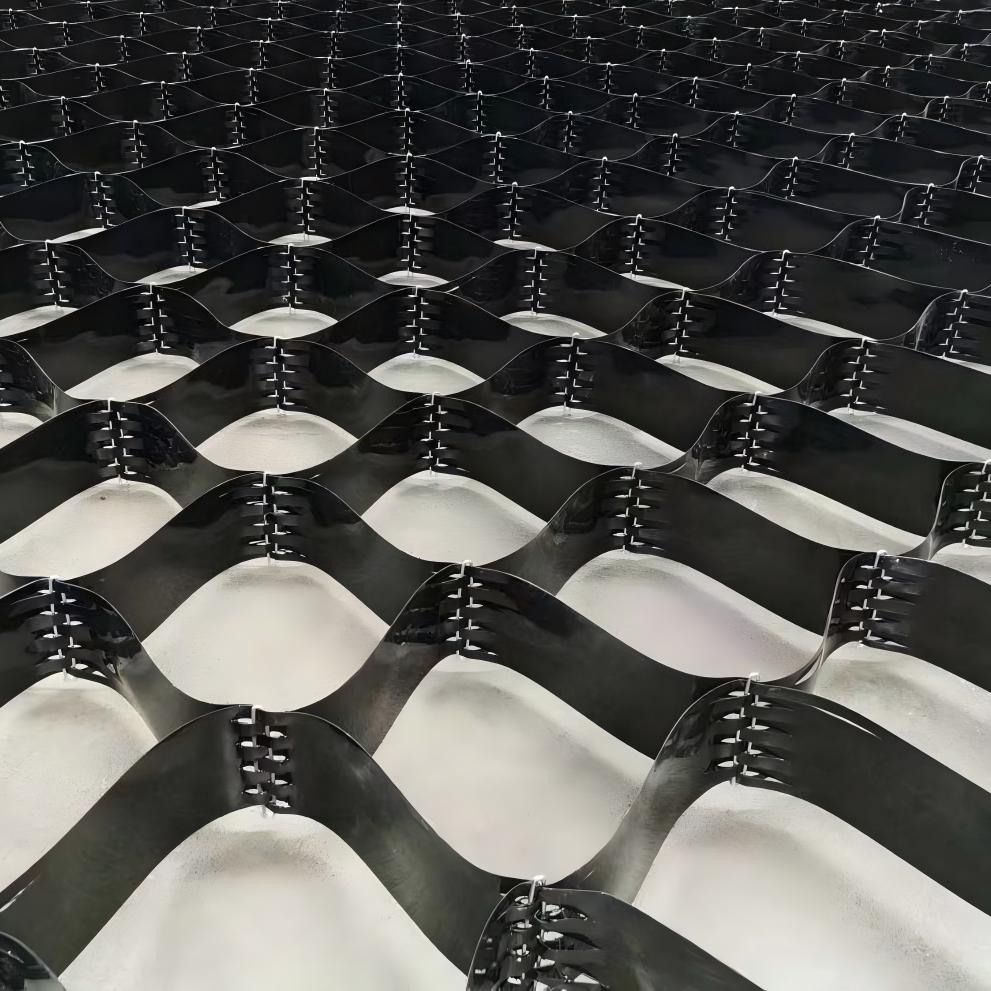

Honeycomb Confinement System

1.Soil Constraint: Restrict the lateral displacement of soil particles to prevent slope landslides and subgrade settlement, especially showing significant effects in the treatment of soft soil foundations.

2.Load dispersion: Evenly transfer the upper load to a larger area of the foundation, reducing the pressure per unit area. It is applicable to load - bearing scenarios such as roads and parking lots.

3.Ecological Protection: The grid can be filled with planting soil and sown with vegetation, combining slope greening and engineering reinforcement, which is suitable for ecological slope protection.

4.Drainage and Permeability: The grid structure itself is permeable and can assist in foundation drainage, reducing the softening effect of water on the soil mass.

Product Introduction:

Honeycomb Confinement System is a new type of geosynthetic material structure designed based on bionics principles. Its core is to confine and reinforce soil or granular materials through a honeycomb - like three - dimensional grid structure, thereby enhancing the stability of engineering structures such as foundations or slopes.

Design Principles and Structural Features

Bionic Inspiration: Imitating the hexagonal honeycomb structure of a bee's honeycomb, leveraging the stability of geometric shapes, each cell can evenly distribute loads to the entire structure when under stress, reducing local stress concentration.

Three - Dimensional Grid Construction: Made of high - strength polymers (such as high - density polyethylene HDPE) through hot - melt welding or injection molding, forming interconnected hexagonal or honeycomb - like three - dimensional grids. The grid size and height can be customized according to engineering requirements.

Combination of Flexibility and Rigidity: A single grid unit has a certain degree of flexibility to adapt to small deformations of the foundation. The overall structure forms a rigid whole by filling materials (such as sand, gravel, soil), enhancing shear and compression resistance.

Product Parameters:

order number | raw and processed material | |||||||

test item | unit | polytene | sulan | polyester | ||||

Extruded type | Stretch type | Extruded type | Stretch type | Extruded type | Stretch type | |||

1 | tensile strength | kN/m | ≥20 | ≥100 | ≥23 | ≥100 | ≥30 | ≥120 |

2 | Tensile yield strain | % | ≤15 | — | ≤15 | — | ≤15 | - |

3 | Tensile fracture strain | % | — | 8~ 20 | — | 6~ 15 | — | 8~ 20 |

4 | Carbon black content a | % | 2. 0~ 3. 0 | |||||

5 | Carbon black dispersion a | — | There should be no more than one level 3 data item in ten data items and no level 4 or 5 data items | |||||

6 | 200℃ oxidation induction time | min | ≥20 | ≥20 | — | |||

7 | Tensile load stress cracking | h | ≥300 | — | ||||

8 | B. Resistance to artificial climate aging retention rateb | % | ≥80 | |||||

9 | Chemical resistance performance retention rate c | % | — | ≥80 | ||||

Product Applications:

Traffic Engineering Field

1. Reinforcement of Highway and Railway Subgrades

Application Scenarios: New construction and repair projects of expressways, national highways, rural roads, and railway subgrades, especially in sections with poor geological conditions such as soft soil foundations and collapsible loess.

Functions: By confining subgrade filling materials (such as crushed stones and gravel) with honeycomb grids, the stress generated by vehicle loads is dispersed, reducing subgrade settlement and uneven deformation and extending the service life of the road. For example, in swampy or soft soil areas, the traditional subgrade is prone to the "springy soil" phenomenon, and the honeycomb system can effectively limit the lateral displacement of the soil and improve the subgrade bearing capacity.

2. Construction of Parking Lots and Logistics Sites

Application Scenarios: Heavy - load areas such as large - scale parking lots, logistics parks, and industrial sites.

Advantages: After filling the grid with gravel or concrete, a rigid pavement is formed, which can withstand high - frequency loads from container trucks, heavy machinery, etc. At the same time, the permeable structure can quickly drain rainwater, avoiding waterlogging on the site. Compared with traditional concrete - hardened ground, the cost is reduced by about 30%, and the construction period is shortened by more than 50%.

Slope and Foundation Pit Engineering

1. Highway and Railway Slope Protection

Application Scenarios: Reinforcement and greening of high slopes, rocky slopes, and weathered soil slopes.

Technical Solutions: Lay the honeycomb system on the slope surface, fill it with planting soil, and then sow grass seeds or shrubs to form a composite protection system of "grid + vegetation". For example, in mountainous highway slopes, this system can not only prevent soil landslides through grid constraints but also fix the soil through the roots of vegetation, achieving the dual goals of engineering safety and ecological restoration.

2. Foundation Pit Support and Temporary Slope Reinforcement

Application Scenarios: Temporary slope support after excavation of building foundation pits, or slope stability control in mining operations.

Features: The flexible grid can adapt to minor slope deformations, avoiding cracking problems caused by foundation settlement in rigid support (such as shotcrete and rock bolts). At the same time, it is convenient for later demolition or ecological restoration.

Water Conservancy and Flood Control Engineering

1. Riparian and River Channel Revetment

Application Scenarios: Embankment protection on both sides of rivers, reservoir dams, and ecological river channel construction. Functions: After filling the grid with pebbles or graded sand and gravel, it can resist water flow scouring and protect the riparian soil from erosion. At the same time, the permeable structure allows the exchange of water bodies and bank slope soil, maintaining the river ecosystem. For example, in ecological revetment projects, the honeycomb system combined with aquatic plants can construct a composite ecological system of "bank stabilization + water purification".

2. Construction of Flood Control Dams and Flood Storage and Detention Areas

Application Scenarios: Reinforcement of flood control dams in flood - prone areas, or construction of temporary roads and dams in flood storage and detention areas.

Advantages: Modular installation facilitates rapid construction, and it can be reused after the flood recedes; the grid structure can disperse the impact load of the flood, reducing the risk of dam breaches.

Ecology and Environmental Engineering

1. Desert Treatment and Sand Fixation in Sandy Areas

Application Scenarios: Desert highway construction, sand fixation at the edge of oases, and sand prevention and control projects.

Technical Principle: Lay the honeycomb system on the sand, and after filling it with clay or sand - fixing materials, it can fix sand grains and prevent shifting sand from eroding roads or farmland.

2. Mine Greening and Ecological Restoration

Application Scenarios: Slope restoration after mine exploitation, and ecological reconstruction in the backfill area of abandoned mine pits.

Implementation Methods: Lay honeycomb grids on steep mine slopes, fill with imported soil (containing nutrient matrix), and then plant drought-tolerant plants. This solves the problem of easy slippage of imported soil in traditional spray seeding greening, and improves the survival rate of vegetation.

Agriculture and Civil Engineering

1. Irrigated Farmland and Terrace Construction

Application Scenarios: Reinforcement of terraced fields in hilly areas, bank protection of farmland irrigation channels.

Functions: The honeycomb system can prevent the collapse of terrace ridges, resist water erosion in channels, and reduce soil erosion. After filling with soil, crops can be planted without affecting farmland cultivation.

2. Landfill Sites and Slope Stability

Application Scenarios: Slope reinforcement and cover layer stabilization of landfill sites.

Features: The grid can restrain the waste body on the slope of the landfill site to prevent landslides; when used in conjunction with an anti-seepage membrane, it can enhance the integrity of the cover layer and reduce the impact of rainwater infiltration on the landfill site.

Special Scenario Applications

1. Military and Emergency Engineering

Application Scenarios: Rapid construction of temporary roads during wartime and emergency rescue passages.

Advantages: It can be folded for transportation, and the filling materials can be quickly deployed on - site to form a load - bearing road surface, meeting the passage requirements of armored vehicles or rescue vehicles.

Coastal and Ocean Engineering

Application Scenarios: Foundation reinforcement for coastal beach roads and land reclamation projects.

Challenges and Responses: To address the problem of seawater corrosion, salt - fog - resistant polymer materials are used. After filling the grid with graded crushed stones, it can resist the impact of ocean waves while allowing seawater to penetrate, reducing damage to the coastal ecosystem.

The application of the honeycomb confinement system always revolves around the dual goals of "engineering safety + ecological protection". Through flexible structural design and material adaptation, it demonstrates remarkable technical economy and environmental friendliness in various complex scenarios.