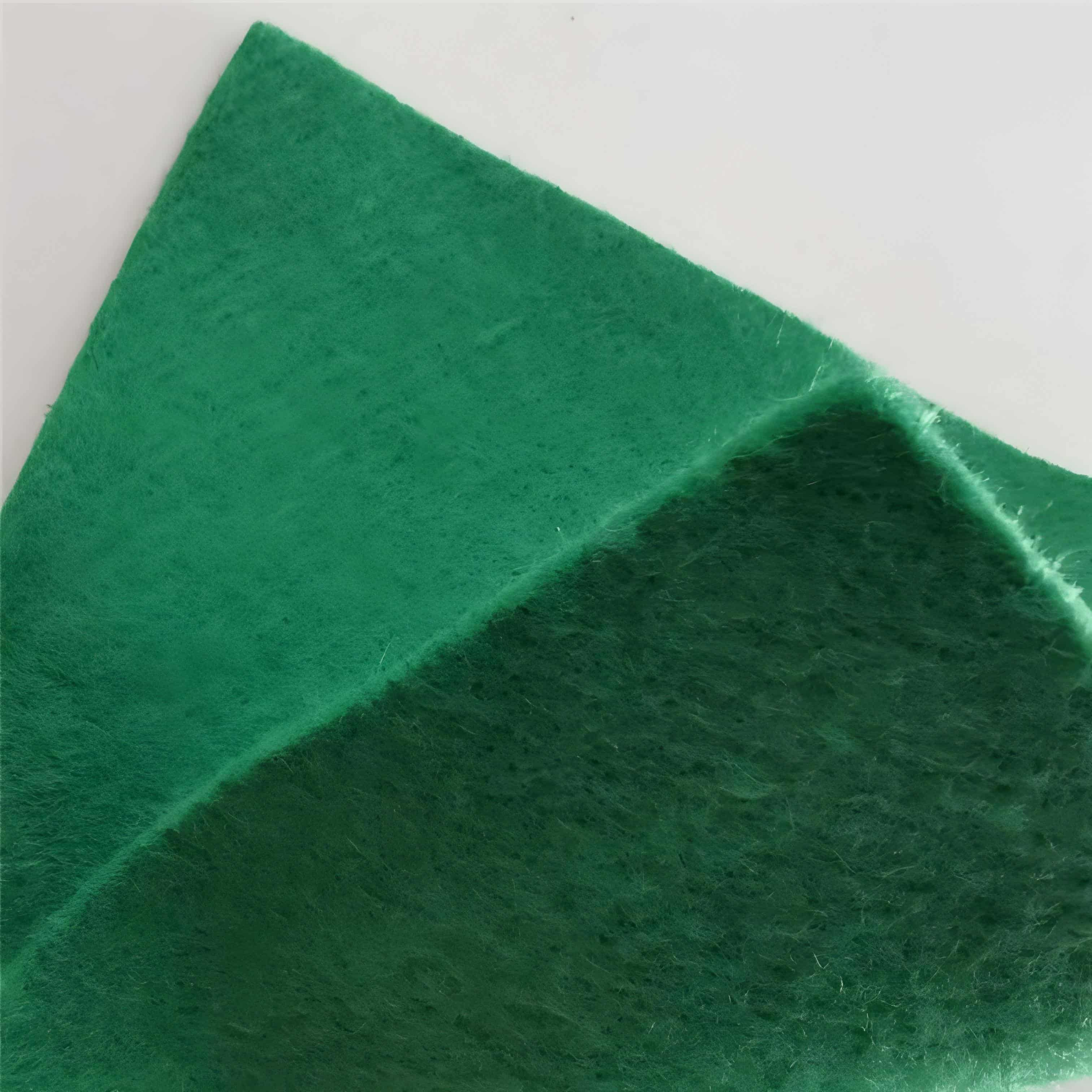

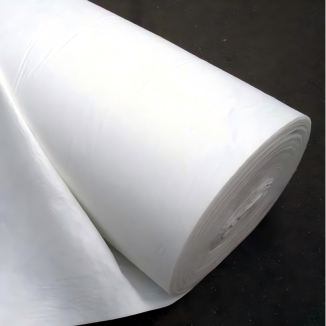

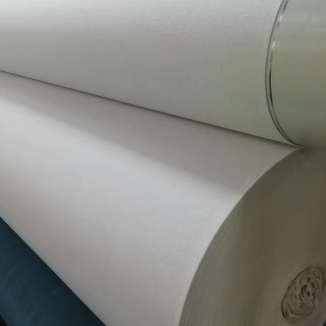

Geotextile 300gr

1. Low cost: replacing traditional materials such as sand and gravel, reducing transportation and construction costs.

2. Long lifespan: Synthetic fibers are resistant to aging and have a service life of several decades.

3. Environmental friendliness: Reduce the extraction of natural materials and partially recycle them.

4. Multifunctionality: It has multiple functions such as reinforcement, filtration, and drainage.

5. Efficient construction: Mechanized laying speed is fast, shortening the construction period.

Product Introduction:

Geotextile 300gr is a permeable geosynthetic material made from synthetic fibers such as polyester, polypropylene, nylon, etc., through processes such as needle punching, weaving, weaving, or spinning. It is not a traditional "fabric", but a functional material with specific engineering properties, mainly used for contact with media such as soil, rock, water, etc., to play a role in reinforcement, isolation, filtration, drainage, etc.

characteristic

1. Excellent physical performance

High strength: Strong tensile, tear resistance, and puncture resistance, capable of withstanding construction and long-term loads.

Good flexibility: able to adapt to foundation deformation, closely adhere to soil, and reduce the risk of uneven settlement.

Strong durability: Wear resistant, UV resistant (some parts have been specially treated), long service life.

2. Permeability and Filtration

Excellent permeability: allowing water to pass freely while effectively preventing soil particle loss and clogging.

Anti filtering effect: It can replace traditional sand and gravel filter layers in hydraulic engineering and protect the stability of soil structure.

3. Chemical stability

Corrosion resistance: acid and alkali resistance, mold resistance, suitable for harsh environments such as saline alkali land and swamps.

Anti biodegradation: Not easily damaged by microorganisms, insects, and ants, maintaining stable performance over the long term.

4. Construction convenience

Lightweight and easy to lay: Lightweight, convenient for transportation, cutting, and mechanized construction, improving efficiency.

Strong adaptability: can be applied to different terrains (such as steep slopes, soft foundations) and complex engineering requirements.

5. Environmental Protection and Economy

Reduce natural material consumption: Replace traditional materials such as sand, gravel, and clay to reduce resource extraction.

Recyclable: Some geotextiles are recyclable, in line with the concept of sustainable development.

Low overall cost: fast construction, minimal maintenance, and significant long-term economic benefits.

Product Parameters:

project | metric | ||||||||||

Nominal strength/(kN/m) | |||||||||||

6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |||

1 | Longitudinal and transverse tensile strength / (kN/m) ≥ | 6 | 9 | 12 | 18 | 24 | 30 | 36 | 48 | 54 | |

2 | Maximum elongation at maximum load in longitudinal and transverse directions/% | 30~80 | |||||||||

3 | CBR top penetration strength /kN ≥ | 0.9 | 1.6 | 1.9 | 2.9 | 3.9 | 5.3 | 6.4 | 7.9 | 8.5 | |

4 | Longitudinal and transverse tearing strength /kN | 0.15 | 0.22 | 0.29 | 0.43 | 0.57 | 0.71 | 0.83 | 1.1 | 1.25 | |

5 | Equivalent aperture O.90(O95)/mm | 0.05~0.30 | |||||||||

6 | Vertical permeability coefficient/(cm/s) | K× (10-¹~10-), where K=1.0~9.9 | |||||||||

7 | Width deviation rate /% ≥ | -0.5 | |||||||||

8 | Unit area mass deviation rate /% ≥ | -5 | |||||||||

9 | Thickness deviation rate /% ≥ | -10 | |||||||||

10 | Thickness coefficient of variation (CV)/% ≤ | 10 | |||||||||

11 | Dynamic perforation | Puncture hole diameter/mm ≤ | 37 | 33 | 27 | 20 | 17 | 14 | 11 | 9 | 7 |

12 | Longitudinal and transverse fracture strength (grab method)/kN ≥ | 0.3 | 0.5 | 0.7 | 1.1 | 1.4 | 1.9 | 2.4 | 3 | 3.5 | |

13 | Ultraviolet resistance (Xenon arc lamp method) | Longitudinal and transverse strength retention rate% ≥ | 70 | ||||||||

14 | Ultraviolet resistance (fluorescence UV lamp method) | Longitudinal and transverse strength retention rate% ≥ | 80 | ||||||||

Product Applications:

1. Transportation Engineering

Highway/railway subgrade:

Isolate soil layers and gravel to prevent mixing and improve roadbed stability.

Disperse loads, reduce road surface settlement and cracks.

Airport runway: Enhance the bearing capacity of the foundation and extend its service life.

Tunnel engineering: used for waterproofing, drainage, and lining protection.

2. Water conservancy engineering

Embankment and River Slope Protection:

As an anti filter layer, it prevents soil erosion while allowing water flow through.

Prevent wave erosion and protect the stability of the bank slope.

Drainage system: used for underground drainage ditches, blind ditches, etc., to enhance drainage efficiency.

Reservoir/channel anti-seepage: Used in conjunction with geomembrane to prevent leakage.

3. Environmental Engineering

Landfill site:

As a drainage layer for leachate, it prevents contamination of groundwater.

Combined with anti-seepage membrane to enhance the anti-seepage effect.

Tailings pond management: prevent tailings loss and reduce environmental pollution.

Artificial wetlands: used for water quality filtration and ecological restoration.

4. Construction Engineering

Basement waterproofing: serves as a drainage layer to prevent groundwater infiltration.

Roof greening: isolate soil from building structures to prevent root damage.

Foundation treatment: Strengthen soft soil foundation and improve bearing capacity.

5. Agriculture and Landscape Architecture

Farmland drainage: Improve soil drainage conditions and prevent waterlogging.

Soil and Water Conservation: Used for slopes and terraces to reduce soil erosion.

Horticultural ground cloth: inhibits weed growth and maintains soil moisture.

6. Other special applications

Coastal protection: prevent wave erosion and reinforce seawalls.

Mining engineering: used for anti-seepage and reinforcement of slag yards.

Emergency flood control: make sandbag substitutes and quickly construct flood barriers.

The application of geotextile covers almost all engineering fields involving soil, water and structural stability, and its multifunctionality and economy make it an important material for modern engineering construction. With the development of technology, the application of geotextiles in emerging fields such as ecological restoration and intelligent engineering is constantly expanding.