HDPE Geomembrane in Mining: Case Study of Tailings Pond Containment Done Right

Mining operations have lengthy confronted the task of safely containing tailings—fine-grained waste substances generated in the course of ore processing. Improper tailings containment can lead to catastrophic environmental damage, regulatory penalties, and reputational harm. Enter HDPE Geomembrane, a high-performance artificial liner that has come to be the gold widespread for tailings pond containment. In this article, we’ll discover how HDPE Geomembrane transforms mining web site safety, dive into a real-world success story, and smash down its key blessings and implementation satisfactory practices.

1. Why HDPE Geomembrane Is Non-Negotiable for Tailings Pond Containment

Tailings ponds require a liner that can face up to harsh mining conditions: chemical publicity from heavy metals in tailings, excessive temperature fluctuations, and steady hydraulic pressure. HDPE Geomembrane tests all these boxes—and more. Unlike normal liners like clay or low-density polyethylene, HDPE Geomembrane affords most excellent chemical resistance, stopping poisonous elements from leaching into soil and groundwater. Its excessive tensile energy and flexibility suggest it can adapt to floor motion barring cracking, a essential function in mining web sites the place terrain balance is frequently unpredictable.

Another key gain of HDPE Geomembrane is its durability. With a lifespan of 50+ years when desirable installed, it reduces long-term renovation expenses and eliminates the want for regular liner replacements. For mining companies, this interprets to considerable value financial savings and multiplied compliance with strict environmental rules (such as the EPA’s Mining Waste Regulations in the U.S. or the EU’s Mine Waste Directive). Unlike different liners that degrade over time, HDPE Geomembrane retains its integrity, making sure constant containment overall performance for decades.

2. Case Study: A Large-Scale Gold Mine’s Tailings Pond Transformation

To illustrate the influence of HDPE Geomembrane, let’s have a look at a case find out about of a massive gold mine in Western Australia. Prior to 2018, the mine relied on a clay liner for its essential tailings pond. After a duration of heavy rainfall, the clay liner developed cracks, main to a small however regarding leak of tailings containing arsenic and mercury. The incident resulted in a $2 million cleanup cost, a 6-month regulatory shutdown, and injury to the mine’s relationship with nearby indigenous communities.

Determined to forestall future issues, the mine’s engineering crew performed a complete evaluate of liner preferences and chosen a 2.0mm thick HDPE Geomembrane. The determination used to be primarily based on the material’s established tune report in comparable mining applications, chemical resistance to gold tailings’ components, and compatibility with the site’s hot, arid climate. The set up procedure commenced with web site preparation: grading the pond base to make sure a clean surface, disposing of rocks and particles that may want to puncture the Geomembrane, and putting in a non-woven geotextile underlay to add an greater layer of protection.

Over 12 weeks, a group of licensed Geomembrane installers laid 150,000 rectangular meters of HDPE liner, the usage of thermal fusion welding to create seamless joints—critical for stopping leaks. Post-installation, the crew performed rigorous testing, inclusive of vacuum checking out of all welds and leak detection surveys the usage of electrical conductivity methods. Since the HDPE Geomembrane set up in 2019, the tailings pond has skilled no leaks. The mine has prevented regulatory fines, decreased preservation charges by means of 40% in contrast to the clay liner era, and restored neighborhood have confidence via its increased environmental performance.

3. Key Considerations for HDPE Geomembrane Installation in Mining

While HDPE Geomembrane is notably effective, its performance relies upon completely on appropriate installation. Mining web sites current special challenges, so right here are the essential steps to make sure success. First, cloth determination should be tailor-made to the precise tailings composition. For example, acidic tailings require HDPE Geomembrane with greater chemical resistance, whilst high-temperature web sites can also want liners with UV stabilization. Working with a official Geomembrane provider to habits cloth trying out is essential.

Site coaching is every other make-or-break factor. Mining tailings ponds are frequently massive and uneven, so grading and compacting the base is necessary to stop liner stress. A geotextile underlay is non-negotiable—it protects the HDPE Geomembrane from punctures induced through rocks, roots, or uneven ground. During installation, welding nice is paramount. Thermal fusion welding creates joints superior than the liner itself, however solely if executed through licensed technicians the usage of calibrated equipment. Post-weld testing, together with air stress checking out and spark testing, need to be a hundred percent comprehensive—no weld ought to go untested.

Finally, ongoing preservation is key to maximizing HDPE Geomembrane lifespan. Regular inspections (quarterly for mining sites) ought to take a look at for symptoms of damage, such as tears, punctures, or weld degradation. Prompt repairs the use of well suited HDPE patches and fusion welding make sure small troubles don’t grow to be primary leaks. The Western Australian gold mine, for example, carried out a month-to-month inspection agenda and has maintained its Geomembrane in pristine circumstance for over 5 years.

4. Cost-Benefit Analysis: HDPE Geomembrane vs. Traditional Liners

Many mining groups firstly hesitate to make investments in HDPE Geomembrane due to its greater upfront fee in contrast to clay or low-density liners. However, a long-term cost-benefit evaluation tells a distinctive story. Let’s examine the Western Australian mine’s prices earlier than and after HDPE Geomembrane installation. The clay liner value $1.2 million to deploy in 2010, however required $300,000 in annual preservation (patching cracks, regrading, and leak repairs). The 2018 leak introduced a $2 million cleanup value and $1.5 million in misplaced manufacturing due to shutdowns.

In contrast, the HDPE Geomembrane set up price $3 million in 2019—but annual protection fees dropped to $180,000. Over 5 years, the mine has saved $2.7 million in preservation and cleanup fees alone, now not such as the fee of averted regulatory fines and misplaced production. Beyond direct costs, HDPE Geomembrane presents intangible benefits: accelerated environmental credibility, which helps tightly closed mining licenses and appeal to investors, and greater neighborhood relations, which reduces the hazard of challenge delays due to public opposition.

For new mining projects, the case for HDPE Geomembrane is even stronger. Advances in manufacturing have decreased HDPE Geomembrane expenses via 15% over the previous decade, whilst set up strategies have turn out to be extra efficient. Many regulatory our bodies now require HDPE Geomembrane for new tailings ponds, making it no longer simply a within your means choice, however a obligatory one.

Conclusion: HDPE Geomembrane—The Foundation of Safe Mining Containment

The Western Australian gold mine’s success story is a testomony to the transformative electricity of HDPE Geomembrane in mining tailings containment. Its most appropriate durability, chemical resistance, and cost-effectiveness over time make it the clear desire for mining corporations searching to guard the environment, comply with regulations, and guard their backside line. From fabric determination to set up and maintenance, each step of the HDPE Geomembrane system is designed to supply reliable, long-lasting containment.

For mining operators nonetheless the use of common liners, the message is clear: investing in HDPE Geomembrane isn’t simply an environmental responsibility—it’s a smart commercial enterprise decision. As the mining enterprise continues to prioritize sustainability, HDPE Geomembrane will stay at the forefront of safe, wonderful tailings pond containment.

Contact Us

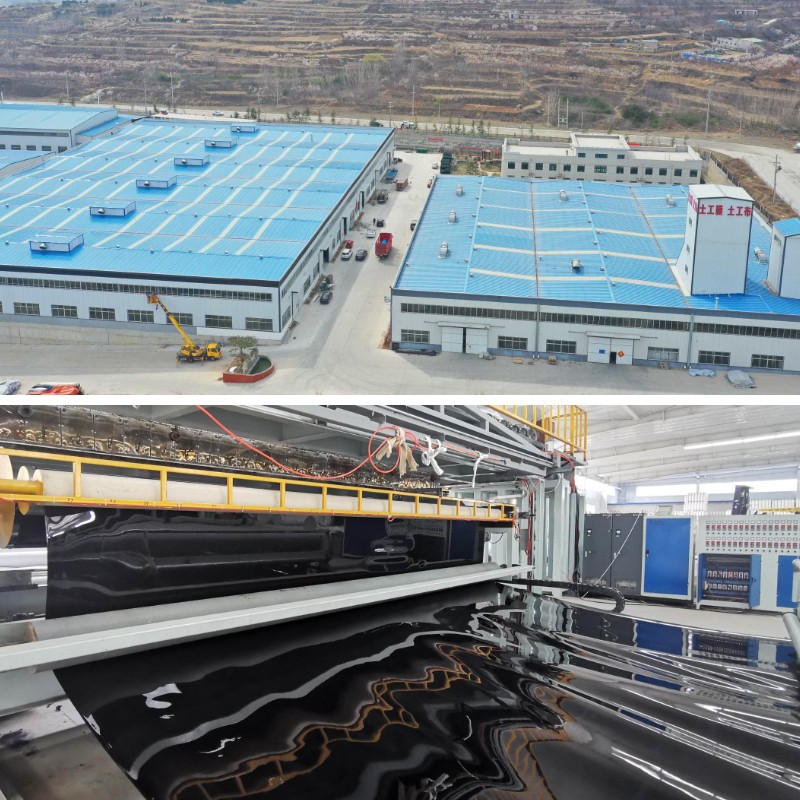

Company Name: Shandong Chuangwei New Materials Co., LTD

Contact Person :Jaden Sylvan

Contact Number :+86 19305485668

WhatsApp:+86 19305485668

Enterprise Email: cggeosynthetics@gmail.com

Enterprise Address: Entrepreneurship Park, Dayue District, Tai 'an City,

Shandong Province