Smooth Geomembrane

1.Excellent anti-seepage capability: The anti-seepage coefficient is extremely low, which can efficiently prevent liquid leakage, prevent water resource loss and pollutant diffusion.

2.Strong chemical stability: resistant to corrosion from strong acids, alkalis, oils, etc., and stable in complex chemical environments.

3.Excellent mechanical properties: high tensile strength, tear resistance, high elongation at break, able to adapt to geological settlement and other working conditions.

4.Weather resistance and durability: anti-aging, high and low temperature resistance, service life up to 30-50 years, reduce maintenance costs.

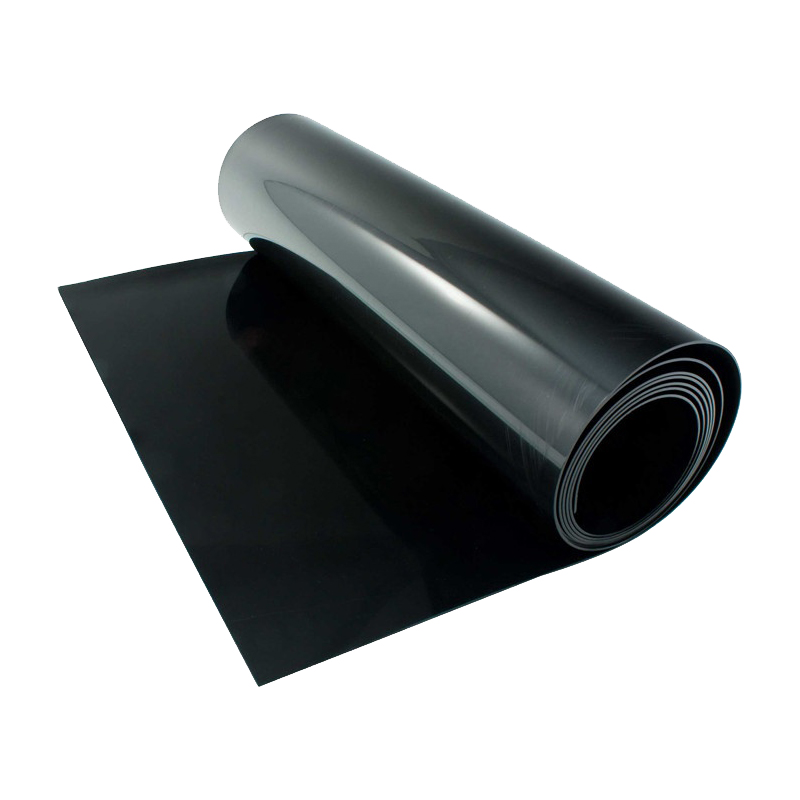

5.Convenient construction: lightweight, easy to transport and lay, high splicing efficiency, and can shorten the construction period.

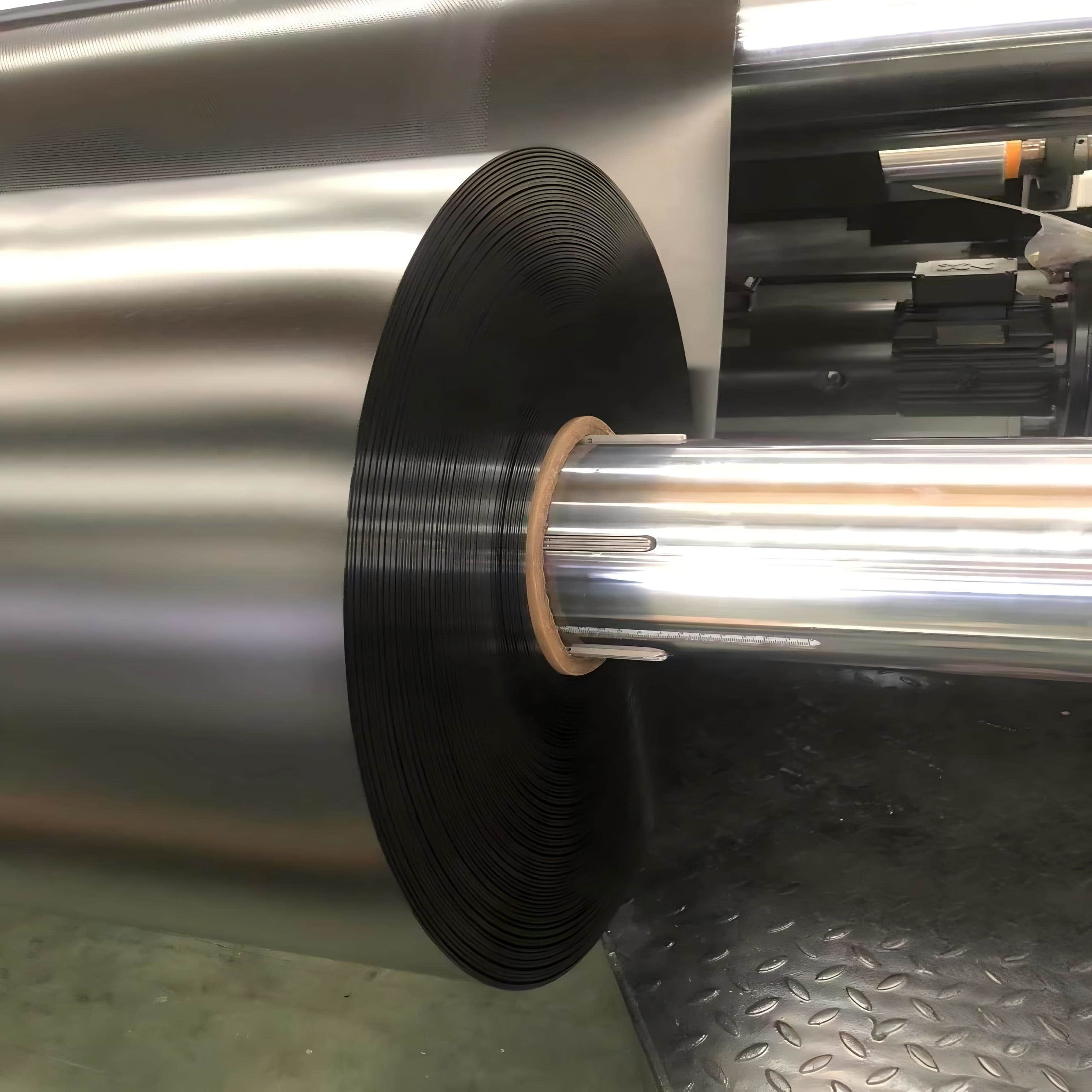

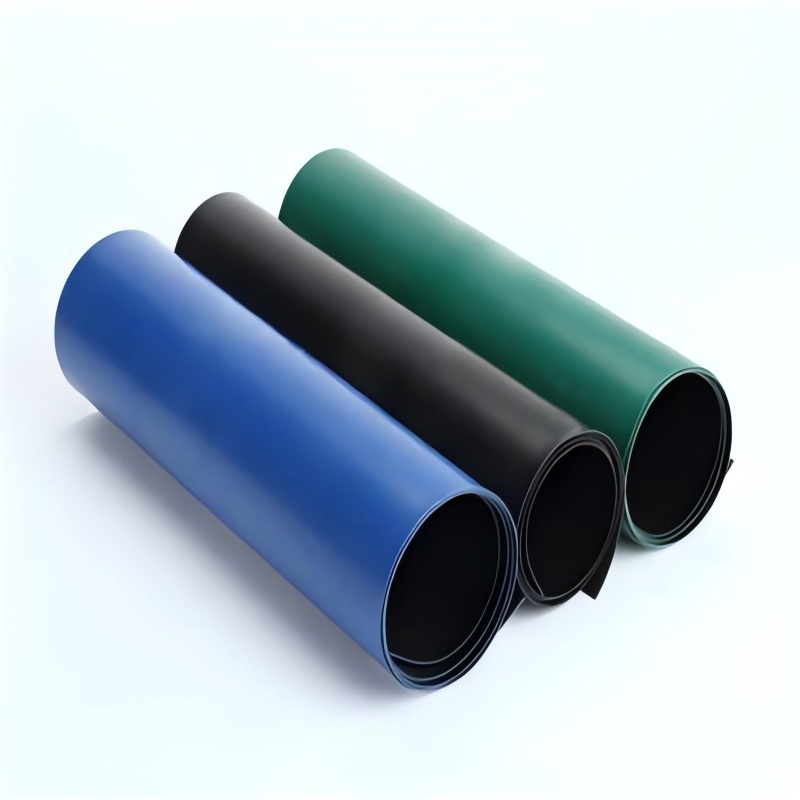

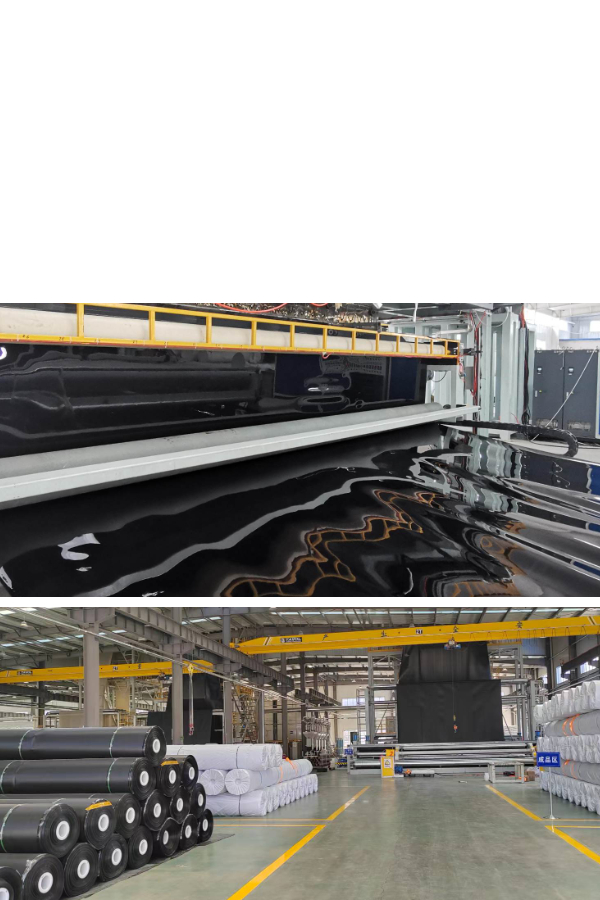

Product Introduction:

Smooth Geomembrane is a waterproof and barrier engineering material made from high molecular weight polymers (such as polyethylene, polyvinyl chloride, etc.) as the core raw material. With excellent anti-seepage performance and comprehensive characteristics, it plays a key role in various civil engineering projects.

Characteristic:

1.Excellent anti-seepage performance: It has extremely low permeability, such as the anti-seepage coefficient of HDPE geomembrane can reach 1 × 10-17 cm/s, which can effectively prevent liquid leakage, prevent water resource loss and pollutant diffusion.

2.Strong chemical stability: able to resist corrosion from strong acids, alkalis, oils and other chemical substances, maintaining stable performance in different chemical environments. It can be used in anti-seepage projects such as sewage treatment tanks and storage tanks in industries such as chemical and electroplating.

3.Good mechanical properties: It has high tensile strength, tensile strength, and elongation at break, and can adapt to uneven geological settlement and various harsh geological and climatic conditions. It plays an important role in the construction of dams, channels, and other structures in hydraulic engineering.

4.Good weather resistance and anti-aging performance: It has strong weather resistance and anti-aging performance, can be exposed for a long time to maintain the original performance, and reduces the maintenance cost and replacement frequency of the project.

5.Convenient construction: light weight, good overall continuity, easy transportation, laying and splicing, fast construction speed, can greatly shorten the project duration, and the impact on the environment during the construction process is relatively small.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

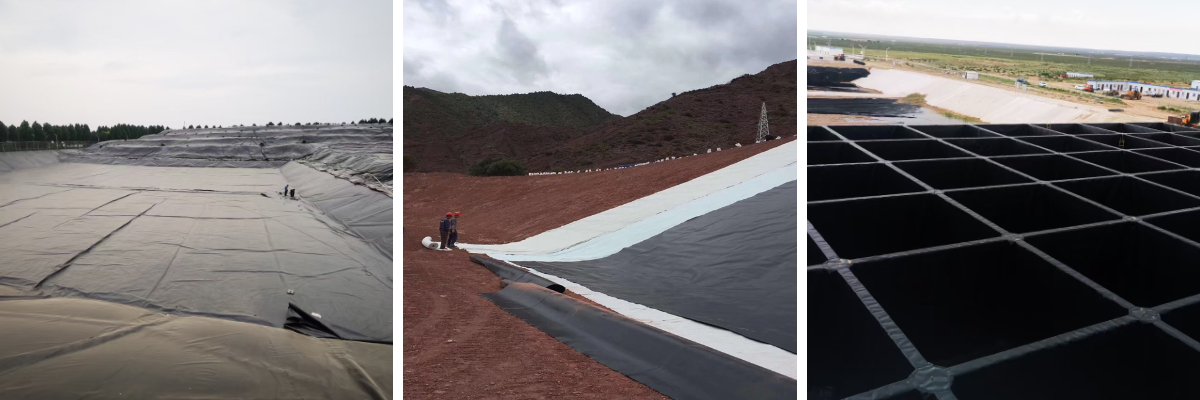

Product Applications:

1.In the field of environmental protection and sanitation, it is widely used for anti-seepage treatment in domestic waste landfills, solid waste landfills, sewage treatment plants, toxic and harmful substance treatment sites, industrial waste yards, etc., to prevent soil and groundwater pollution caused by leachate and pollutant leakage from garbage.

2.Water conservancy engineering: it is used for seepage prevention and reinforcement of Rivers and Lakes, reservoirs, dams, seepage prevention of canals, vertical core walls, slope protection and other projects, to improve the waterproof performance and stability of water conservancy facilities and reduce the leakage loss of water resources.

3.In the field of municipal engineering, it can be applied to underground engineering of subways and buildings, as well as waterproofing of roof reservoirs and gardens, lining of sewage pipelines, etc., to ensure the normal operation of urban infrastructure, prevent groundwater infiltration and sewage leakage.

4.In the field of landscaping, it is commonly used for the bottom lining and slope protection of artificial lakes, ponds, and golf courses, creating beautiful landscape water bodies while preventing water leakage and saving water resources.

5.In the mining industry, it plays an important role in the bottom lining anti-seepage of washing tanks, heap leaching tanks, ash yards, dissolution tanks, sedimentation tanks, storage yards, and tailings ponds to prevent pollution of the surrounding environment caused by slag, tailings, etc.

In short, geomembranes have achieved the engineering value of "efficient barrier+long-term stability" through material technology, and are one of the core materials for controlling leakage and protecting ecology in modern engineering.