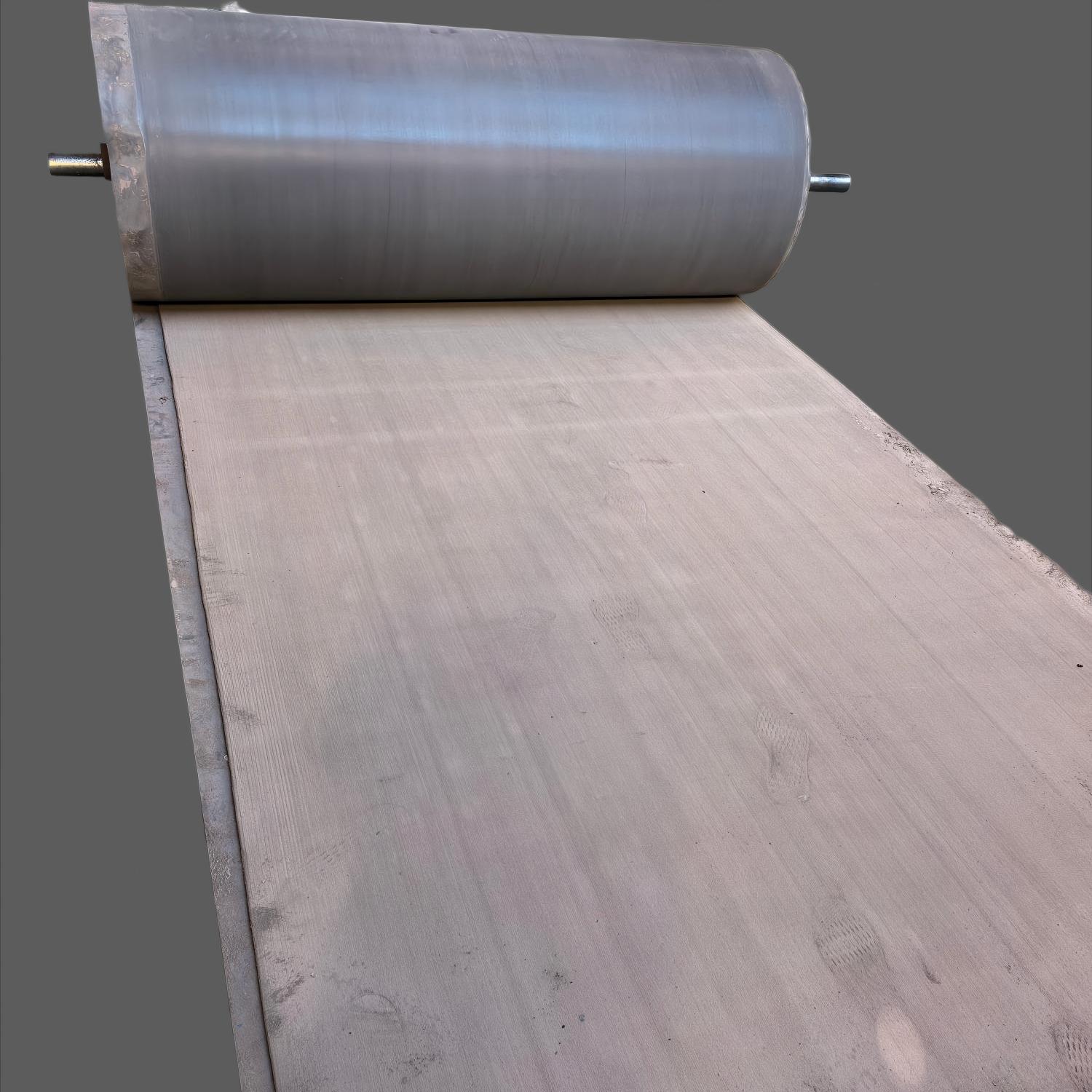

Concrete Curing Tarps

1.Rapid Installation:

No mixing, pouring, or curing required—simply add water, and it hardens within 24 hours, saving over 90% of construction time.

2.Lightweight & Flexible:

Roll-form transportation, only 1/10 the weight of traditional concrete, and can be cut to fit complex terrain.

3.Eco-Friendly:

Reduces material waste, lowers carbon emissions, and requires no heavy machinery.

4.High Durability:

Compressive strength exceeds 20 MPa, with corrosion resistance, UV stability, and a lifespan of over 50 years.

Product Introduction:

Concrete Curing Tarps are a flexible fabric impregnated with a specially formulated cement-based material, composed of a three-dimensional fibrous framework (e.g., polyethylene/polypropylene) bonded with dry concrete mix. Upon hydration with water, the cement undergoes a chemical reaction, hardening within 24 hours into a thin, waterproof, and fire-resistant concrete structure that combines the fabric’s cuttability with concrete’s durability.

Core Features

1.Flexible & Malleable

Can be freely rolled, cut, and shaped before curing, adapting to complex terrains (e.g., curved surfaces, trenches) without requiring formwork or heavy machinery, offering high construction flexibility.

2.Rapid Curing

Adjustable plasticity within 2 hours after watering, achieving 80% of its strength in 24 hours—significantly reducing project timelines (traditional concrete requires 7+ days).

3.Lightweight

Weighs only 5–10 kg per square meter (traditional concrete: ~2,400 kg/m³), lowering transportation and labor installation costs.

4.High Durability

Resists impact, chemical corrosion, and UV exposure post-curing, with a service life exceeding 50 years, making it suitable for harsh environments.

5.Eco-Friendly & Energy-Efficient

Reduces material consumption by 95% and carbon emissions by 70% compared to traditional concrete, aligning with green building standards.

Product Parameters:

| Property | State | 8mm | 10mm | 12mm | 15mm | Test Method | |

| Compressive strength(MPa) | cured 28 days | 60 MPa | D8329 | ||||

| Flexural strength(MPa) | cured 28 days | 15 MPa | D8058 | ||||

| Pyramid puncture(kN) | cured 28 days | 4.0 kN | 4.5 kN | 5.0 kN | 6.0 kN | D5494,Type B | |

| Abrasion (maximum value) | cured 28 days | 0.3 mm/1000 cycles | C1353/C1353M | ||||

| Tensile strength | Final | uncured | 20 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | D6768/D6768M |

| Initial | cured 28 days | 15 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | D4885 | |

| Final | 25 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | |||

| Freeze-thaw | Residual initial flexural strenath(D8058) | cured 28 days, 200 cycles | >80 % (Pass) | C1185 | |||

| Water quality requirements for hydration | Tap water、River water、Seawater | / | |||||

| Construction temperature conditions | Construction above 0℃ | ||||||

| Fire protecting performance | B1 | GB 8624-2012 | |||||

| Harmful substance leaching test items | Limitation index (mg/L) | GB 5085.3-2007 | |||||

| Copper (total copper) (mg/L) | ≤100 | ||||||

| Zinc (total zinc) (mg/L) | ≤100 | ||||||

| Cadmium (total) (mg/L) | ≤1 | ||||||

| Lead (total lead) (mg/L) | ≤5 | ||||||

| Total chromium (mg/L) | ≤15 | ||||||

| Nickel (total nickel) | ≤5 | ||||||

| Arsenic (total) | ≤5 | ||||||

Product Applications:

1.Infrastructure Emergency Repair

Flood Control Dams: Rapid construction of temporary flood barriers, such as emergency dike reinforcement during the 2023 Beijing-Tianjin-Hebei flood disaster.

Road Repair: Restoration of war-damaged roads or post-disaster reconstruction, exemplified by temporary road paving in earthquake-stricken areas.

2.Water Conservancy Projects

Canal Lining: Applied for irrigation canal seepage prevention, reducing leakage rates by 90% in a Xinjiang irrigation district.

Reservoir Slope Protection: Replacing traditional concrete slope protection, improving construction efficiency by 400%.

3.Slope Protection

Mine Rehabilitation: Covering exposed slopes to prevent landslides and dust pollution.

Highway Slopes: Enhancing slope stability and reducing maintenance costs by 70% on a section of the Sichuan-Tibet Highway.

4.Military & Emergency Response

Field Fortifications: Rapid deployment of bunkers or temporary camps, as utilized by the U.S. military in Afghanistan for base construction.

Post-Disaster Shelters: Used for temporary housing foundations after the Turkey earthquake.

5.Civil Applications

Roof Waterproofing: Replacing traditional waterproofing membranes to extend service life to 30 years.

Fish Pond Slope Protection: Preventing seepage and achieving 30% water conservation in a fish farming operation.

This translation preserves technical accuracy while ensuring clarity for international audiences, emphasizing key performance metrics and real-world applications.

Concrete cloth, through its revolutionary design, resolves the cumbersome and time-consuming challenges of traditional concrete construction, particularly excelling in emergency projects and complex environments, marking a significant innovation in modern engineering materials.