Geo-Tube

1.Efficient Dewatering:

The geotextile allows water to seep out while retaining solid particles, accelerating sludge dewatering.

2.Cost-Effective & Eco-Friendly:

Compared to traditional cofferdams or concrete structures, it offers lower costs and reduces carbon emissions.

3.Easy Installation:

Adaptable to complex terrains, requiring no heavy machinery, and forms a stable structure directly after filling.

4.High Durability:

UV-resistant and corrosion-resistant, suitable for harsh environments.

Product Introduction:

Geo-Tube is a large tubular container made of high-strength geotextile fabric. It is filled with slurry, sludge, or fine-grained materials through hydraulic filling technology. By utilizing the filtration and drainage functions of the fabric, it achieves solid-liquid separation and ultimately forms a stable geotechnical structure.

Product Features

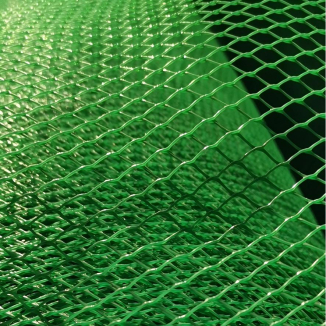

Material: Made of high-strength woven/non-woven geotextile fabric (PP or PET) with excellent tensile strength and permeability.

Specifications: Typically 1~5 meters in diameter, with customizable length (up to several tens of meters).

Filtration Performance: Controlled pore size ensures effective retention of fine particles while enabling rapid drainage.

Flexible Structure: Adapts to ground deformation, offering superior seismic resistance compared to rigid structures.

Product Parameters:

project | unit | CWGD50S | CWGD90/120 | CWGD90S | CWGD100S | CWGD120S-B | CWGD120S-C | CWGD130S | CWGD200S-C | |

Tensile strength-radial | kN/m | 55 | 90 | 90 | 100 | 130 | 130 | 130 | 220 | |

Tensile strength-Weft | 50 | 120 | 90 | 100 | 120 | 120 | 130 | 210 | ||

Strain elongation-radial | % | 16±1 | 12±1 | 9±1 | 10±1 | 10±1 | 10±1 | 10±1 | 12±1 | |

Extensional elongation-Weft | 10±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | 8±1 | ||

Breakage strength at 2% elongation | warp direction | kN/m | 5/15 | 14/40 | 30/30 | 30/30 | 20/40 | 22/40 | 20/45 | 15 |

Breakage strength at 5% elongation | warp direction | kN/m | 14/33 | 38/90 | 75/75 | 75/75 | 80/100 | 84/40 | 80/110 | 90 |

mass area ratio | g/m² | 285 | 440 | 390 | 430 | 540 | 540 | 560 | 850 | |

Joint tensile strength | kN/m | 35 | 90 | 60 | 70 | 100 | 100 | 110 | 170 | |

Static Burst Strength (CBR) | KN | 5 | 10 | 10 | 13 | 15 | 15 | 16 | 22 | |

Dynamic perforation | mm | 10 | 8 | 12 | 12 | 10 | 10 | 11 | 8 | |

Equivalent aperture (0g0) | mm | 0.9 | 0.48 | 0.52 | 0.45 | 0.4 | 0.3 | 0.43 | 0.4 | |

Permeability (Q50) | L/m²/s | 200 | 40 | 20 | 15 | 12 | 6.5 | 15 | 15 | |

Ultraviolet resistance (500h strong storage rate ) | % | 90 | 90 | 85 | 85 | 85 | 85 | 85 | 85 | |

Product Applications:

1.Water Conservancy Engineering

Embankments and Cofferdams: Replaces traditional riprap revetments, saving material costs and accelerating construction speed. Suitable for soft soil foundations or areas lacking stone materials.

River Dredging and Sediment Treatment: Dewatering and solidification of sediment using geotextile tubes reduce sludge volume and prevent secondary pollution.

2.Marine Engineering

Bank Protection and Breakwaters: Filled geotextile tubes form the core of structures to resist wave impacts and protect coastlines.

Artificial Islands and Land Reclamation: Enables rapid construction of temporary or permanent structures, reducing engineering costs.

3.Environmental Engineering

Sludge and Tailings Treatment: Efficient dewatering and solidification minimize landfill requirements and achieve harmless disposal.

Ecological Restoration: Solidified materials can be reused for greening or landfill, improving ecological environments.

4.Transportation Engineering

Soft Foundation Treatment: Serves as temporary access roads or work platforms to enhance ground bearing capacity.

Subgrade Reinforcement: Strengthens roadbed stability through reinforcement effects.

5.Mining and Chemical Industries

Tailings Pond Construction: Filled geotextile tubes form isolation layers to prevent tailings leakage.

Contaminated Site Remediation: Solidifies heavy metal-contaminated soil to reduce environmental risks.

Geotextile tubes have become a crucial solution in modern geotechnical engineering and environmental remediation due to their efficiency, cost-effectiveness, and eco-friendliness, particularly suitable for projects requiring rapid dewatering and consolidation.