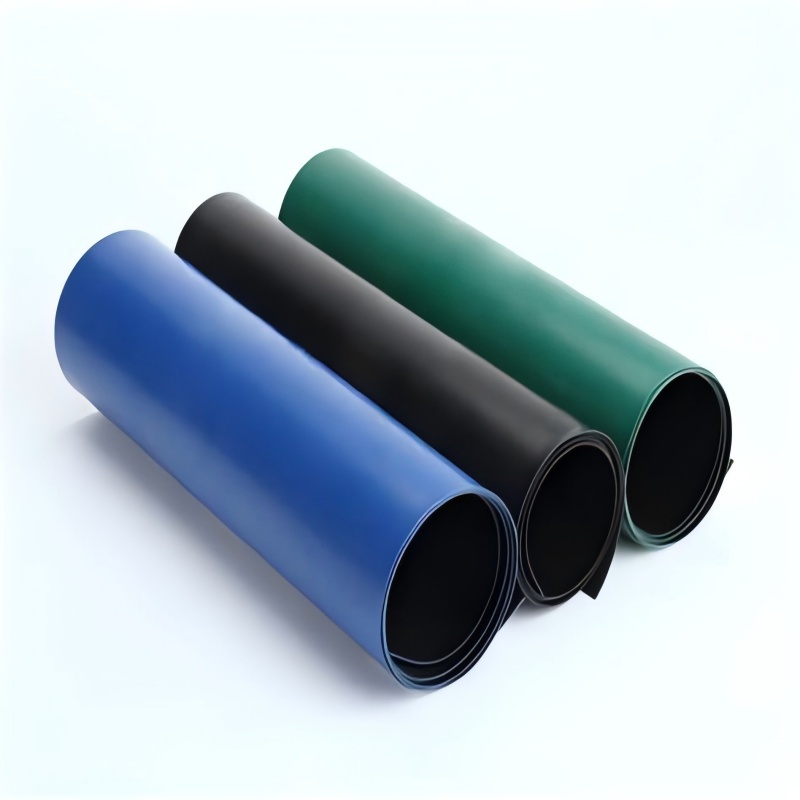

Impermeable Geomembrane Liner

1.High Impermeability:

Extremely low permeability coefficient (≤10⁻¹³ cm/s), effectively preventing the penetration of liquids and gases.

2.Chemical Resistance:

Resistant to acids, alkalis, salts, oils, and other chemicals, making it suitable for harsh environments.

3.Strong Anti-Aging Properties:

UV-resistant additives extend outdoor service life.

4.Flexible & Durable:

Adapts to ground deformation with excellent tear and puncture resistance.

5.Easy Installation:

Lightweight, weldable or bondable, ensuring high laying efficiency.

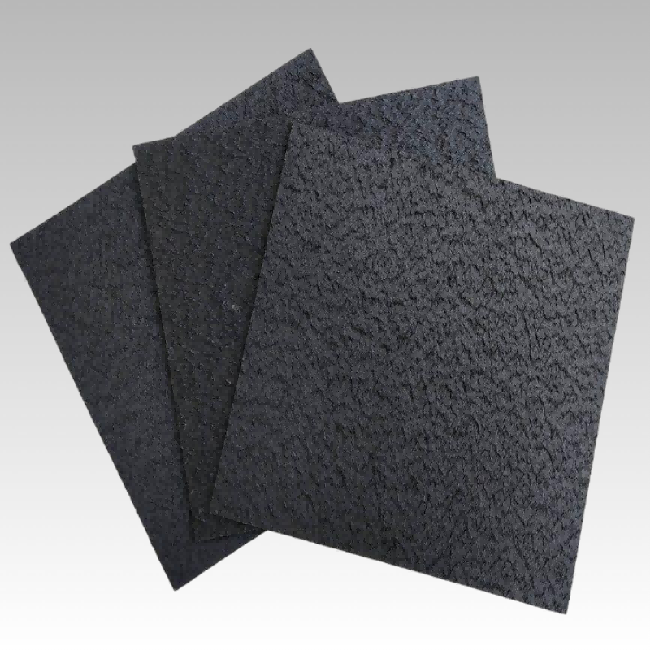

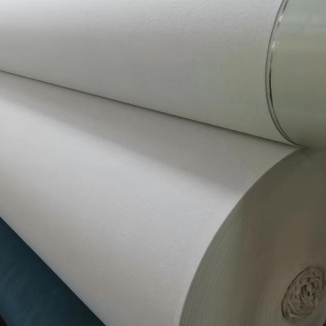

Product Introduction:

Impermeable Geomembrane Liner is a flexible waterproof and barrier material made from high-molecular polymers (such as polyethylene, polyvinyl chloride, EVA, etc.) through processes like extrusion, blow molding, or calendaring. Its core function is to prevent the penetration of liquids, gases, or solid particles through physical barrier action, making it widely applied in engineering fields for seepage prevention, isolation, and reinforcement.

Features

1.Excellent Flexibility: Adapts to uneven ground settlement, preventing cracks caused by soil deformation.

2.UV Resistance: Contains antioxidants and light stabilizers to resist material degradation from prolonged sun exposure.

3.Eco-Friendly & Safe: Made from non-toxic materials, compliant with environmental standards, suitable for potable water tanks and aquaculture.

4.Various Specifications: Customizable thickness, width, and special functions (e.g., reinforced or composite geomembranes) based on project requirements.

Product Parameters:

Metric | ASTM | unit | Test value | Minimum test frequency | ||||||

test method | 0.75 mm | 1.00 mm | 1.25 mm | 1.50 mm | 2.00 mm | 2.50mm | 3.00 mm | |||

Minimum average thickness | D5199 | mm | 0.75 | 1 | 1.25 | 1.5 | 2 | 2.5 | 3 | Per volume |

Minimum value (any one of 10) | -10% | -10% | -10% | -10% | -10% | -10% | -10% | |||

minimum density | D 1505/D 792 | g/cm3 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 0.94 | 90,000 kg |

Minimum average tensile performance (1) | D638 Type IV | |||||||||

Breakage strength, | N/mm | 20 | 27 | 33 | 40 | 53 | 67 | 80 | 9,000 kg | |

yield strength | N/mm | 11 | 15 | 18 | 22 | 29 | 37 | 44 | ||

Strain extension, | % | 700 | 700 | 700 | 700 | 700 | 700 | 700 | ||

yield extension | % | 12 | 12 | 12 | 12 | 12 | 12 | 12 | ||

Minimum strength of right-angle tear | D 1004 | N | 93 | 125 | 156 | 187 | 249 | 311 | 374 | 20,000 kg |

Minimum puncture strength | D4833 | N | 240 | 320 | 400 | 480 | 640 | 800 | 960 | 20,000 kg |

Constant tensile load stress cracking (2) | D5397 | hour | 300 | 300 | 300 | 300 | 300 | 300 | 300 | Based on GRI GM-10 |

Carbon black content | D 1603(3) | % | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 2.0-3.0 | 9,000 kg |

Carbon black dispersion | D5596 | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | Note (4) | 20,000 kg | |

Oxygen induction time (OIT) (5) | 90,000 kg | |||||||||

(a) Standard OIT | D3895 | minute | 100 | 100 | 100 | 100 | 100 | 100 | 100 | |

(b) high-handed OIT | D5885 | minute | 400 | 400 | 400 | 400 | 400 | 400 | 400 | |

85℃ Oven aging (minimum average) (5)(6) | Per formula | |||||||||

(A) Standard OIT is retained after 90 days | D 5721 | % | 55 | 55 | 55 | 55 | 55 | 55 | 55 | |

(B) High voltage OIT is retained for 90 days | D 3895 D5885 | % | 80 | 80 | 80 | 80 | 80 | 80 | 80 | |

Ultraviolet resistance (7) | Per formula | |||||||||

(a) standard OIT | D3895 | Note (8) 50 | ||||||||

(b) Retention of high pressure OIT after 1600 hours (9) | D5885 | % | ||||||||

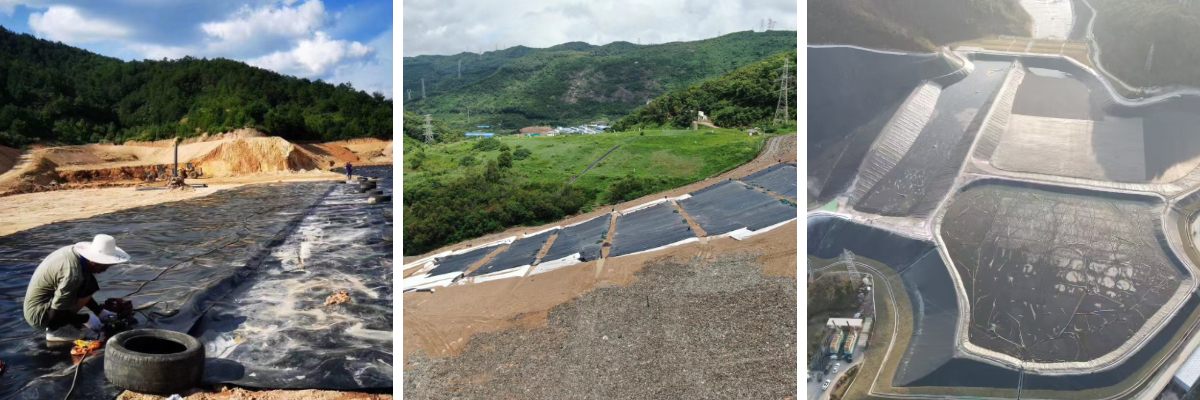

Product Applications:

1.Hydraulic Engineering

Anti-seepage for reservoir dams, river channel lining, water storage tank leakage prevention, irrigation channel anti-seepage, etc.

2.Environmental Protection Engineering

Anti-seepage layers for landfills, anti-leakage for sewage treatment ponds, isolation for industrial waste residue yards, protection for hazardous waste treatment sites, etc.

3.Transportation Engineering

Reinforcement and anti-seepage for highway and railway subgrades, tunnel waterproofing, isolation for airport runway foundations, etc.

4.Agricultural Engineering

Anti-leakage for fish ponds and shrimp ponds, anti-seepage for biogas digesters, moisture-proof layers for agricultural greenhouses, isolation layers for saline-alkali land improvement, etc.

5.Energy Engineering

Anti-seepage for petrochemical storage tank foundations, isolation for nuclear power plant waste treatment sites, anti-seepage layers for LNG storage tank bottoms, etc.

6.Mining Engineering

Anti-seepage for tailings ponds, anti-leakage for mine wastewater treatment ponds, isolation for mine road foundations, etc.

With its exceptional impermeability and durability, geomembranes have become an indispensable material in modern engineering construction, widely used in seepage control, isolation, and protective applications.